High-temperature-resistant heat-insulation fireproof sleeve and preparation method thereof

A fireproof casing, high temperature resistance technology, applied in the direction of thermal insulation protection of pipes, heat exchange equipment, hoses, etc., can solve the problem of low temperature resistance effect of fireproof casing, achieve good heat insulation effect, low accident loss, The effect of high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

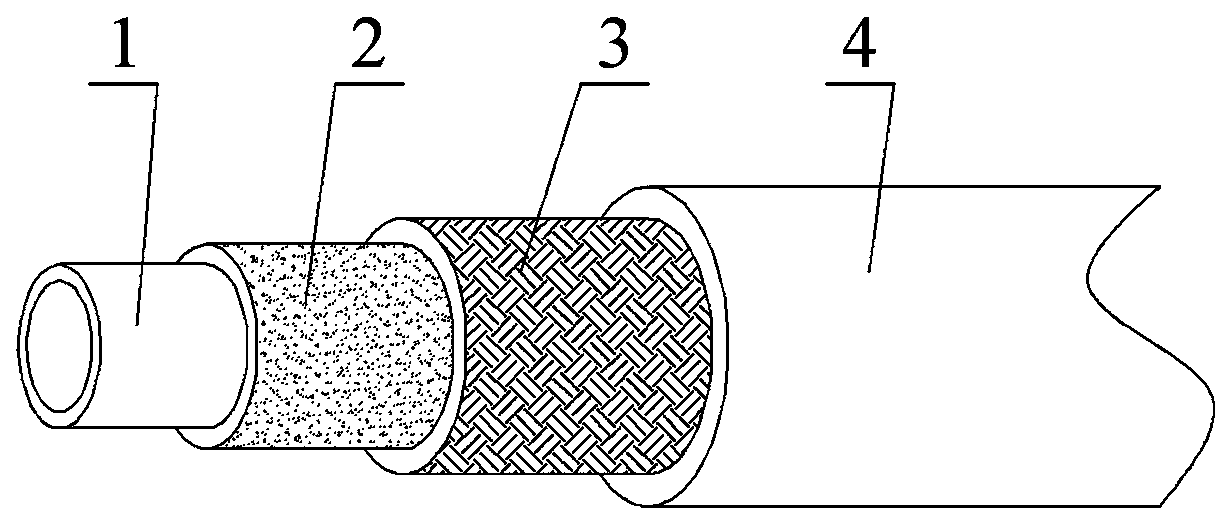

[0031] A method for preparing a high-temperature-resistant heat-insulating fireproof casing, comprising the following steps:

[0032] Step 1: using a continuous molding process to prepare a heat-resistant resin hose as the skeleton layer 1;

[0033] Step 2: Wrap the airgel on the outer layer of the skeleton layer as the heat insulation layer 2;

[0034] Step 3: use three-dimensional weaving equipment to weave heat-resistant fibers on the outer layer of the heat insulation layer 2 as the braided layer 3;

[0035] Step 4: Coating the outer layer of the braided layer 3 with a high-temperature-resistant flame-retardant material as the coating layer 4; if the coating layer 4 is rubber, further vulcanization is required.

Embodiment 1

[0037] The heat-resistant material used in the skeleton layer of the fireproof casing is PTFE resin, the airgel used in the heat-insulating layer is silica airgel, and the heat-resistant fiber used in the braided layer is continuous glass The fiber has a monofilament diameter of 13 μm, and the material used for the cladding layer is flame-retardant silicone rubber.

Embodiment 2

[0039] The heat-resistant material used in the skeleton layer of the fireproof casing is PFA resin, the airgel used in the heat insulation layer is alumina airgel, and the continuous fiber used in the braided layer is continuous carbon fiber, which The diameter of the monofilament is 7μm, and the material used for the cladding layer is flame-retardant fluororubber.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com