Ultrasonic flow measurement method and device

A flow measurement device and flow measurement technology, applied in the ultrasonic field, can solve problems such as increasing system complexity, increasing flow measurement error, and large number of side tones, so as to avoid inconsistent probe frequencies, ensure measurement range, and shorten response time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

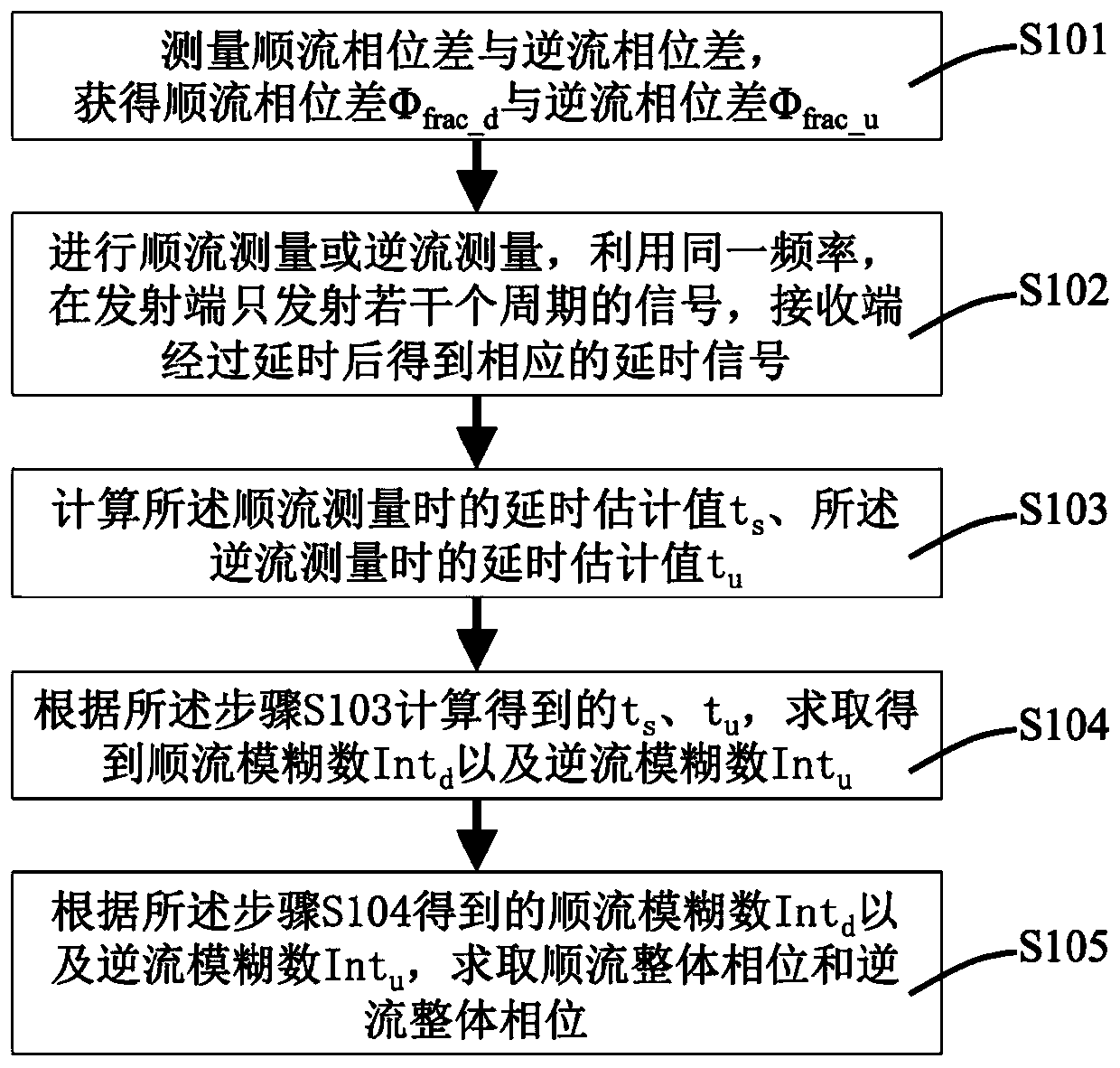

[0069] Example 1: Ultrasonic flow measurement method

[0070] In order to solve the problem that the measurement response time caused by multiple frequencies is slow, the embodiment of the present invention only uses one frequency (generally the highest frequency is taken, and this frequency is generally set to the resonant frequency of the ultrasonic probe, or a frequency close to the resonant frequency of the ultrasonic probe. ) to achieve the above measurement problem.

[0071] Specifically, please refer to the flowchart image 3 shown. An ultrasonic flow measurement method, comprising the following steps:

[0072] S101: Measure the downstream phase difference and the upstream phase difference to obtain the downstream phase difference Φ frac_d Phase difference Φ with reverse flow frac_u ;

[0073] S102: Perform downstream measurement or countercurrent measurement, using the same frequency, only transmit signals of several cycles at the transmitting end, and the receivi...

Embodiment 2

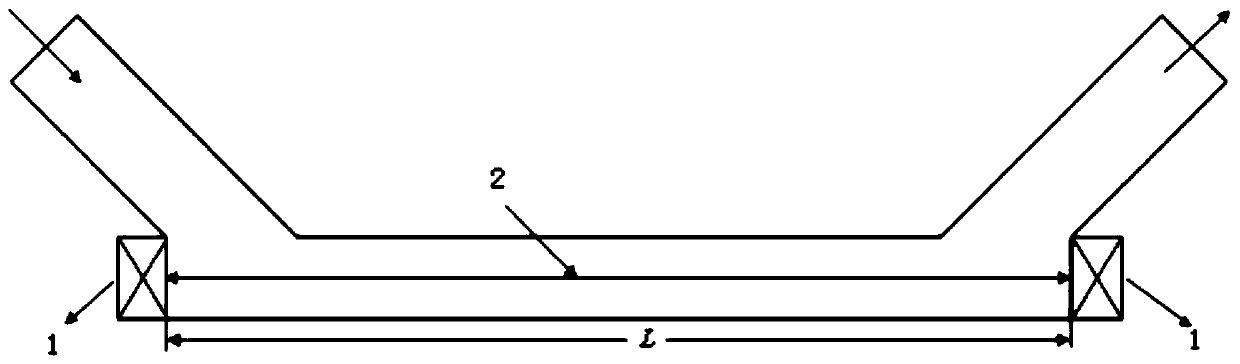

[0091] Example 2: Ultrasonic flow measurement device

[0092] For the embodiments of the present invention, please refer to Image 6 As shown, an ultrasonic flow measurement device includes:

[0093] Phase difference measurement module 3, used to measure the downstream phase difference and the upstream phase difference, and obtain the downstream phase difference Φ frac_d Phase difference Φ with reverse flow frac_u ;

[0094] Ultrasonic detection module, the ultrasonic probe has a transmitting end 4 and a receiving end 5, the transmitting end 4 is used to transmit only several cycles of signals using the same frequency, and the receiving end 5 is used to receive the corresponding signal after a delay. delay signal;

[0095] Delay estimation value calculation module 6, used to calculate the delay estimation value t during downstream measurement s , the estimated delay value t during downstream measurement u ;

[0096] The fuzzy number obtaining module 7 is used for calcul...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap