Capillary microfluidic reactor with controllable fixed area of catalytic material and preparation method

A technology of catalytic materials and fixed areas, applied in chemical instruments and methods, chemical/physical/physical chemical reactors, chemical/physical processes, etc., can solve the problem that small volumes cannot meet large-scale production needs, and materials cannot be fixed in capillaries Problems such as the inner wall and uncontrollable material area, etc., to achieve good fixing effect, good and consistent catalytic effect, and stable reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

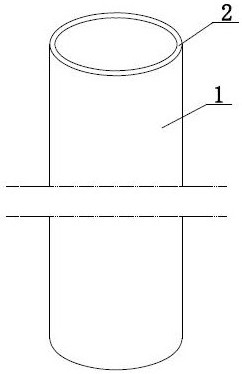

[0034] The reactor preparation method in this example is used to prepare a full-area capillary microfluidic reactor, including the following steps:

[0035] (1) PDMS prepolymer and curing agent are prepared in a mass ratio of 5:1-30:1 to prepare PDMS liquid, stir and mix with a clean glass rod, and stir for 5-10 minutes. The ratio of PDMS prepolymer and curing agent preparation will affect the viscosity of the prepared PDMS liquid, and the PDMS liquid prepared by the aforementioned ratio has the viscosity of sticking capillary and powder.

[0036] (2) Put the mixed PDMS liquid into a vacuum desiccator, and use a vacuum pump to remove the air bubbles in the liquid. The air bubbles in the liquid will affect the coating effect of PDMS on the inner wall of the capillary. The vacuuming time is 10-20 minutes. The prepared mixed PDMS liquid was stored in a -20°C refrigerator for later use.

[0037] (3) Take a clean and dry round glass capillary with a diameter of 0.3-1.1mm. Pick up...

example 2

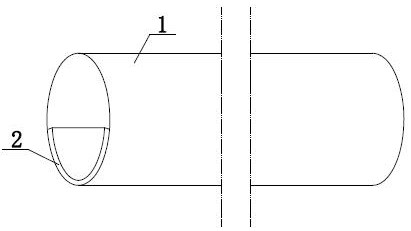

[0041] The reactor preparation method in this example is used to prepare a capillary microfluidic reactor in a partial area, including the following steps:

[0042] (1) Prepare PDMS liquid with PDMS prepolymer and curing agent at a ratio of 5:1-30:1, stir and mix with a clean glass rod, and stir for 5-10 minutes.

[0043] (2) Put the mixed PDMS liquid into a vacuum desiccator, and use a vacuum pump to remove the air bubbles in the liquid. The air bubbles in the liquid will affect the coating effect of PDMS on the inner wall of the capillary. The vacuuming time is 10-20 minutes. The prepared mixed PDMS liquid was stored in a -20°C refrigerator for later use.

[0044] (3) Take a clean and dry round glass capillary with a diameter of 0.3-1.1mm. Pick up an appropriate amount of PDMS liquid with a clean syringe needle, fill it from one end of the capillary until the length of the PDMS liquid column in the capillary is 1.1-4.4mm, and the length of the capillary is 11cm. Fix the ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com