A high-efficiency polishing method suitable for post-sintering type metal 3D printing

A 3D printing, high-efficiency technology, applied in the field of powder metallurgy, can solve the problems of easy deformation of product appearance, increase the difficulty of polishing, and difficult operation of printed parts, so as to improve practicability and popularity of industrial applications, improve polishing efficiency and polishing Integrity, reduced mechanical force and time effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

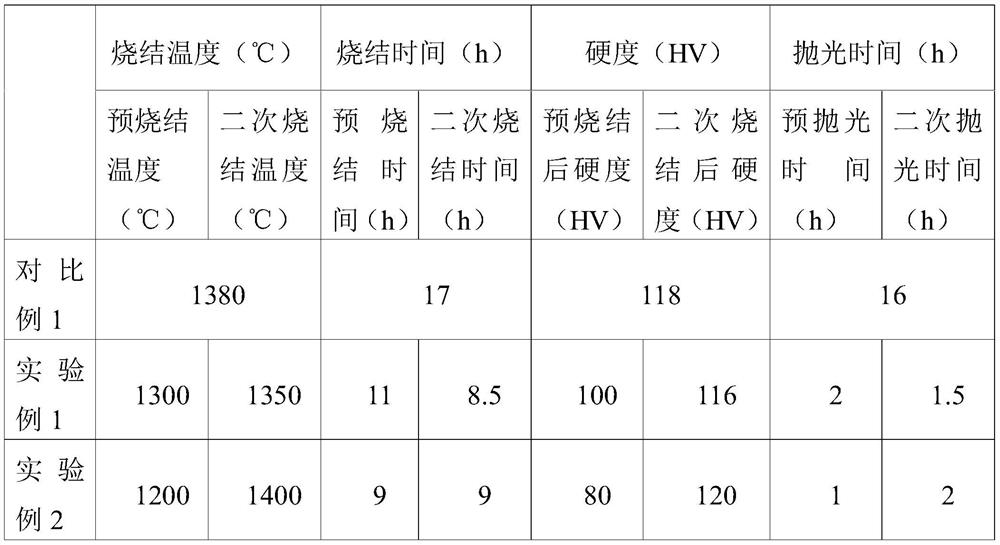

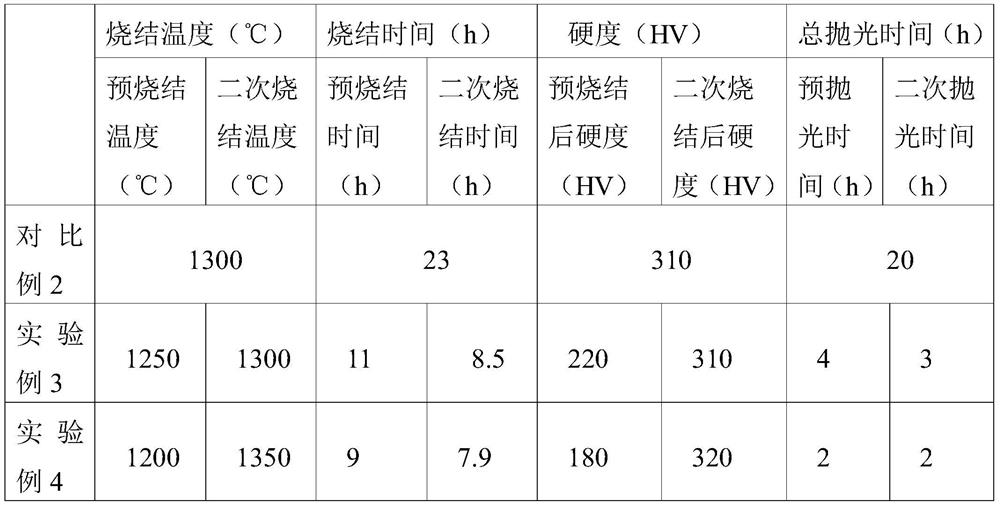

[0034] Example 1: Randomly select 3 classic stainless steel hooks (material 316L) common in the metal 3D printing technology industry for experimental illustration. Comparative Example 1 is to randomly select one of the classic stainless steel hooks through traditional methods. The sintered parts after sintering are polished, and the remaining 2 classic stainless steel hooks are used in Experimental Example 1 and Experimental Example 2 respectively, and Experimental Example 1 and Experimental Example 2 are polished by the polishing method provided by the present invention; The polishing time required for the final finished surface of 3 stainless steel classic hooks to reach the mirror roughness is used as a comparison standard.

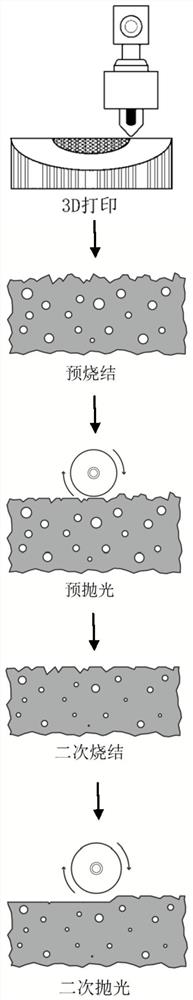

[0035] A high-efficiency polishing method suitable for post-sintering type metal 3D printing, comprising the following steps:

[0036] Step S1, using 3D printing technology to obtain printed parts;

[0037] Step S2, putting the obtained printed parts...

experiment example 1

[0041] The pre-sintering and secondary sintering in Experimental Example 1 were carried out in vacuum sintering furnaces with temperatures of 1300°C and 1350°C respectively, and the pre-sintering and secondary sintering times were 11 hours and 8.5 hours respectively;

experiment example 2

[0042] The pre-sintering and secondary sintering in Experimental Example 2 were carried out in vacuum sintering furnaces with temperatures of 1200°C and 1400°C respectively, and the pre-sintering and secondary sintering times were 9 hours and 9 hours respectively;

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com