Flaming system of ardealite calcinator

A calciner and phosphogypsum technology, which is applied in the field of flame injection systems, can solve problems such as affecting combustion efficiency, low crushing efficiency, and insufficient oxygen supply, and achieve the effects of improving combustion efficiency, achieving environmental protection standards and saving, and reducing coal consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

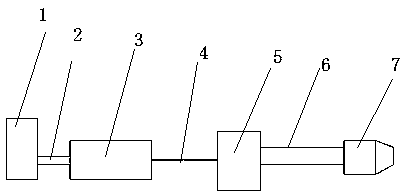

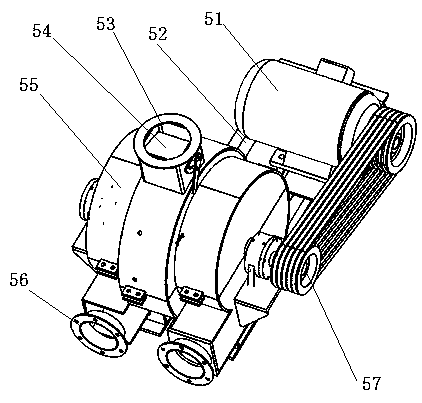

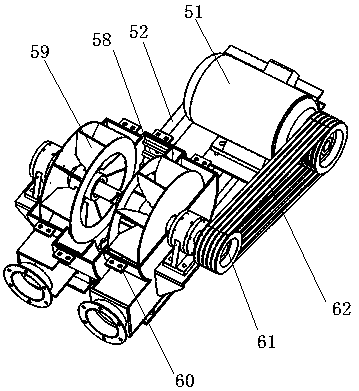

[0021] In order to further illustrate the technical solution of the present invention, the specific implementation manner of the present invention is now described in conjunction with the accompanying drawings, as Figure 1-Figure 3 , select the common commercially available variable frequency speed regulating motor in this industry as the variable frequency speed regulating motor 51 in this example, the described frequency variable speed regulating motor 51 is installed on the base 52, and is fixedly connected with the base 52; Select steel welding in this example As the base 52, the base 52 is installed on the lower part of the variable-frequency speed-regulating motor 51 and the lower housing 60, and fastened with bolts; in this example, a circular or rectangular pipe end with a flange commonly used in this industry is selected. The interface is used as the coal inlet air inlet 53, the coal inlet air inlet 53 is installed on the upper casing 55, the lower end is airtightly w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com