Snow-melting and deicing epoxy asphalt mixture and preparation method thereof

A technology of epoxy asphalt and mixture, which is applied in the field of road construction materials, can solve the problems of rapid attenuation of snow melting and deicing functions, corrosion of road surfaces, and reduction of road surface durability and service life, so as to reduce the occurrence of rutting diseases and resist vehicles. Good effect of load action and water stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Material preparation

[0038] The epoxy asphalt mixture for melting snow and deicing according to the present invention, according to the ratio of parts by mass, takes epoxy asphalt A component bisphenol A type epoxy resin (E-51) (place of origin: Nantong Xingchen Synthetic Materials Co., Ltd. Company) 1.7 parts, epoxy asphalt B component long carbon chain acid anhydride curing agent (origin: Shanxi Hualuxiang Technology Co., Ltd.) 0.2 parts, epoxy asphalt C component 70# base asphalt (origin: Shanxi Hualuxiang Technology Co., Ltd.) 2.9 parts, basalt aggregate (origin: Jiangsu Jurong Maodi) 96 parts, IceBane environment-friendly asphalt pavement ice and snow inhibitor (snow melting agent provided by Xi'an Huabo Transportation Technology Co., Ltd.) 6 parts, epoxy asphalt , The performance index of IceBane environment-friendly asphalt pavement ice and snow inhibitor is shown in Table 1-2.

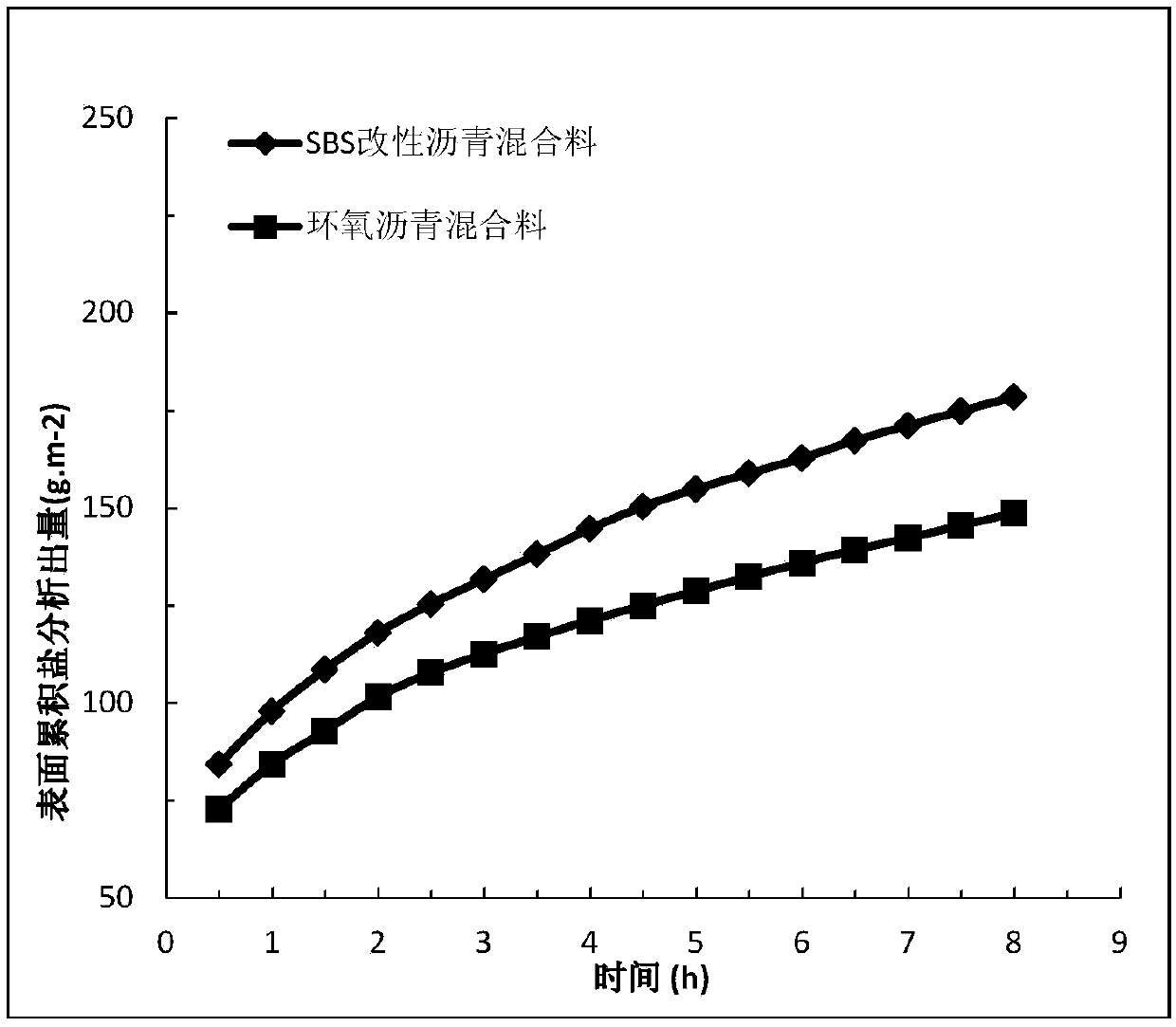

[0039] In order to facilitate comparative analysis, SBS modified asphalt is u...

Embodiment 2

[0071] (1) Material preparation

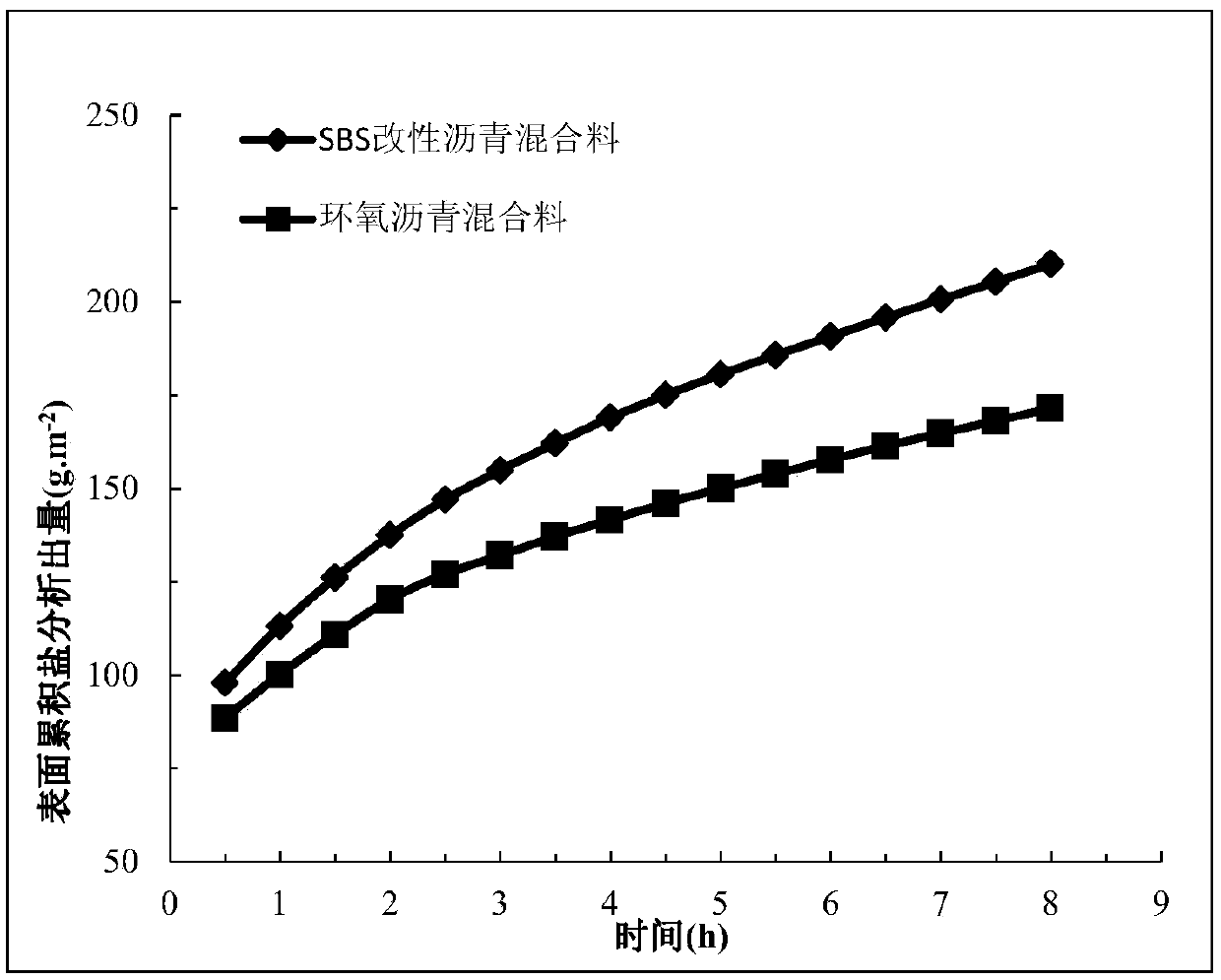

[0072] The epoxy asphalt mixture for melting snow and deicing according to the present invention, according to the ratio of parts by mass, takes 2.6 parts of epoxy asphalt A component bisphenol A type epoxy resin (E-51), epoxy asphalt B group 0.2 parts of acid anhydride curing agent with long carbon chain, 3.0 parts of epoxy asphalt C component 70# base asphalt, 96 parts of basalt aggregate, 7 parts of IceBane environmental protection type asphalt pavement ice and snow inhibitor, IceBane environmental protection type asphalt pavement ice and snow inhibitor The performance index is the same as that in Example 1, and the epoxy asphalt technical index is shown in Table 6. In order to facilitate comparative analysis, SBS modified asphalt is used for performance comparison, which is 5.8 parts by mass, and its performance index is the same as that of Example 1. The consistency of oxygen asphalt mixture. The aggregate gradation adopts the continuou...

Embodiment 3

[0088] (1) Material preparation

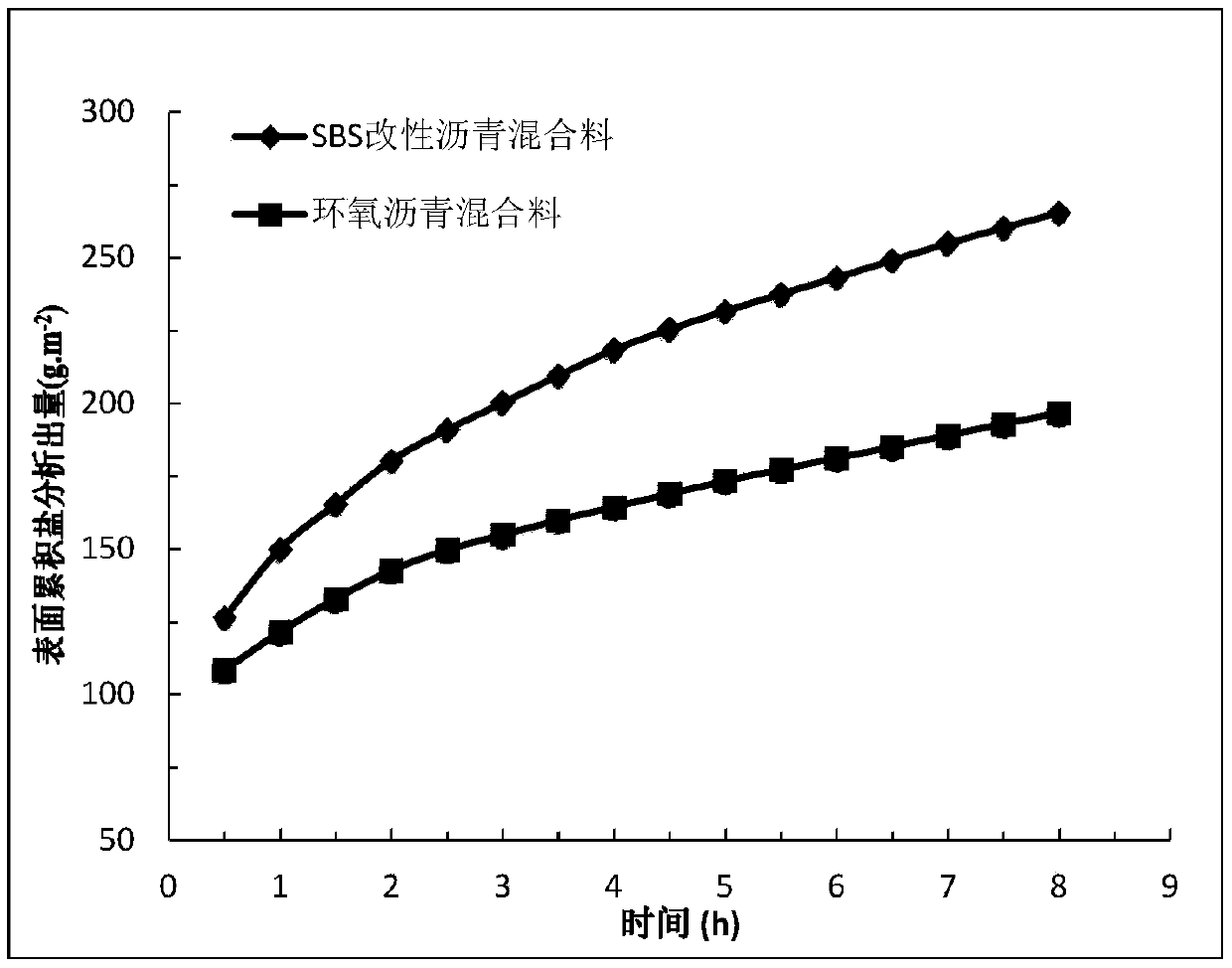

[0089]The epoxy asphalt mixture for melting snow and deicing according to the present invention, according to the ratio of parts by mass, takes 0.7 part of epoxy asphalt A component bisphenol A type epoxy resin (E-51), epoxy asphalt B group 0.4 parts of acid anhydride curing agent with long carbon chain, 3.8 parts of epoxy asphalt C component 70# matrix asphalt, 96 parts of basalt aggregate, 8 parts of ice and snow inhibitor of IceBane environment-friendly asphalt pavement, epoxy asphalt, IceBane environment-friendly asphalt The performance indexes of road ice and snow inhibitors are shown in Tables 9-10. In order to facilitate comparison and analysis, SBS modified asphalt is used for performance comparison. The ratio of parts by mass is 4.9 parts, and its performance index is the same as that of Example 1. Consistency of asphalt mixture. The aggregate gradation adopts the continuous dense gradation (AC-20) curve, and its nominal maximum par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com