PCB capable of detecting depth of back drilling hole and detection method

A PCB board and detection method technology, which is applied in the field of PCB boards for detecting the depth of back-drilled holes, can solve the problems affecting the signal transmission and quality of PCB boards, the depth and accuracy of back-drilled holes are not easy to grasp, and increase the production cost of PCB boards, etc. To achieve the effect of reducing the scrapping of slices, optimizing the control method, and shortening the detection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

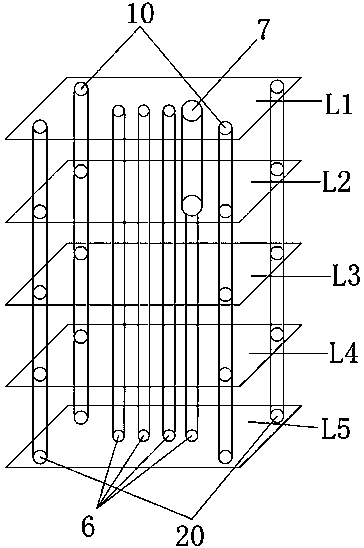

[0019] Referring to the accompanying drawings, a PCB board capable of detecting the depth of a back-drilled hole includes a PCB board formed by stacking layers of L1, L2, L3, L4 and L5 from top to bottom in sequence, and a test hole is provided on the PCB. It is a through hole, and the test holes include 2 short-circuit test holes 10 and 2 open-circuit test holes 20, and a circuit is arranged on each layer of the board, and the 2 short-circuit test holes 10 and 2 open-circuit test holes 20 form a loop connected with the circuit respectively , the PCB board is provided with at least one through-hole A6 except the test hole, copper plating in the through-hole A connects the 5-layer board for communication, and at least one through-hole A6 is provided with a back-drilled hole 7, the through-hole A is connected to The circuit of the short test hole and the circuit connecte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com