Processing method of Pukeng tea

A processing method and technology for Pukeng tea, applied in the field of tea processing and production, can solve problems such as uneven quality of tea leaves, achieve the effects of improving production efficiency, avoiding hidden dangers of quality and safety, and shortening aging time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

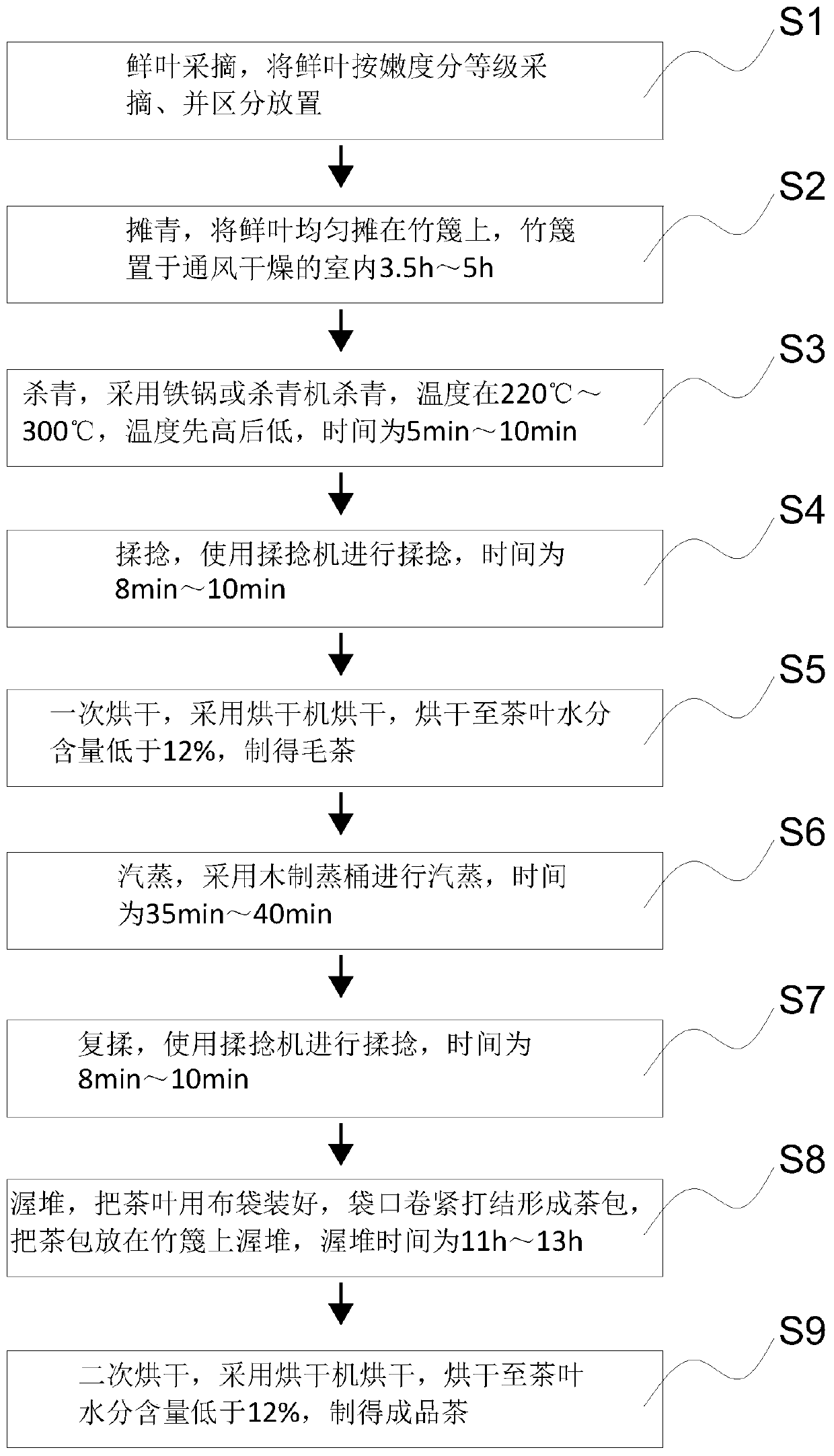

Method used

Image

Examples

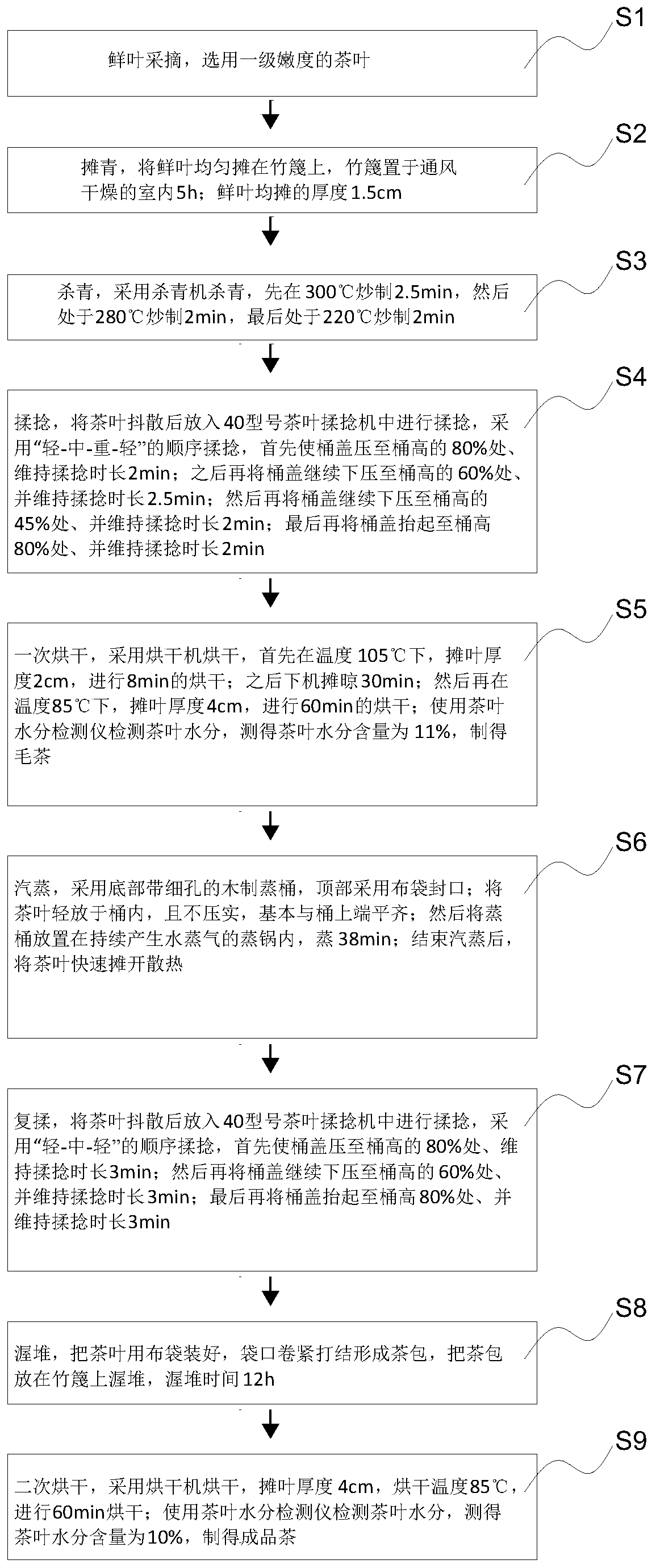

Embodiment 1

[0051] S1, picking fresh leaves, using tea leaves with first-grade tenderness;

[0052] S2, spread green, spread the fresh leaves evenly on the bamboo strips, place the bamboo strips in a ventilated and dry room for 5 hours; the thickness of the fresh leaves evenly spread is 1.5cm;

[0053] S3, greening, using a greening machine to finish, first frying at 300°C for 2.5 minutes, then frying at 280°C for 2 minutes, and finally frying at 220°C for 2 minutes;

[0054] S4, kneading, loosen the tea leaves and put them into a 40-type tea kneading machine for kneading. Knead in the order of "light-medium-heavy-light". Firstly, press the barrel lid to 80% of the height of the barrel and keep rolling for a long time. 2min; then continue to press down the lid to 60% of the height of the barrel, and keep kneading for 2.5min; then continue to press down the lid to 45% of the height of the barrel, and keep kneading for 2min; Lift the lid to 80% of the height of the barrel, and keep kneadin...

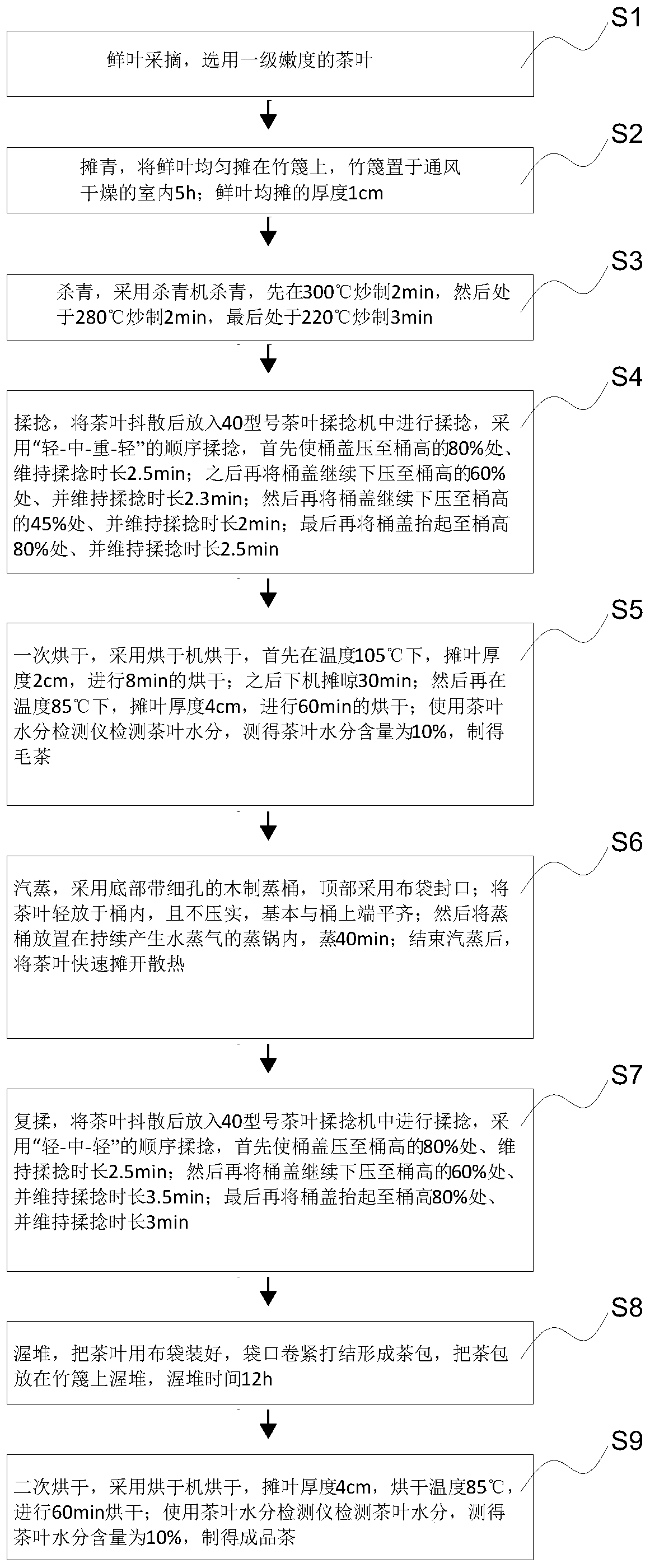

Embodiment 2

[0061] S1, picking fresh leaves, using tea leaves with first-grade tenderness;

[0062] S2, spread green, spread the fresh leaves evenly on the bamboo strips, and place the bamboo strips in a ventilated and dry room for 5 hours; the thickness of the fresh leaves spread evenly is 1cm;

[0063] S3, greening, using a greening machine to finish, first frying at 300°C for 2 minutes, then frying at 280°C for 2 minutes, and finally frying at 220°C for 3 minutes;

[0064] S4, kneading, loosen the tea leaves and put them into a 40-type tea kneading machine for kneading. Knead in the order of "light-medium-heavy-light". Firstly, press the barrel lid to 80% of the height of the barrel and keep rolling for a long time. 2.5min; then continue to press down the lid to 60% of the height of the barrel, and keep kneading for 2.3min; then press down the lid to 45% of the height of the barrel, and keep kneading for 2min; finally Lift the lid to 80% of the height of the barrel, and keep kneading ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com