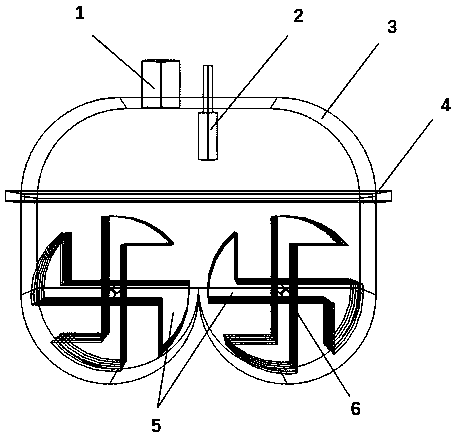

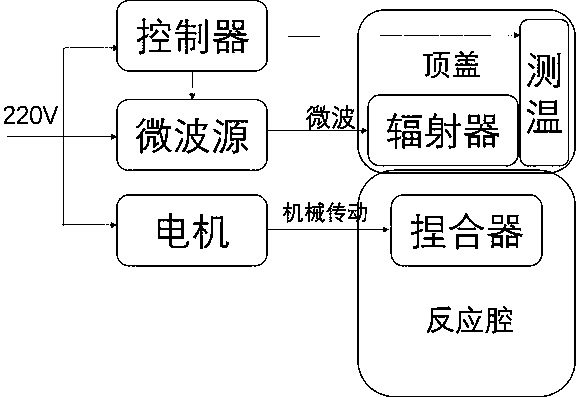

Microwave reaction kettle with kneader

A microwave reaction, microwave technology, applied in chemical instruments and methods, chemical/physical/physical-chemical processes, chemical/physical/physical-chemical processes of applied energy, etc. problems, to achieve the effect of improving the reaction rate and product quality, improving heating efficiency, and good temperature control function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Use the above-mentioned equipment for the synthesis of agricultural ammonium polyphosphate water-soluble fertilizer, use urea and phosphoric acid as raw materials to synthesize ammonium polyphosphate, set the microwave power to 500w, and set the reaction temperature to 170°C, and the agricultural polyphosphoric acid can be synthesized in only 8 minutes under microwave radiation heating Ammonium water-soluble fertilizer products; the microwave power is 1000W, and the reaction temperature is set at 160°C, which can synthesize agricultural ammonium polyphosphate water-soluble fertilizer products in 6 minutes. However, conventional heating is used to synthesize agricultural ammonium polyphosphate products, which usually requires about 3 hours of heating reaction.

Embodiment 2

[0033] Use the above-mentioned equipment for the synthesis of ammonium polyphosphate flame retardant, synthesize low-water-soluble ammonium polyphosphate with phosphoric acid and melamine as raw materials, microwave power 600W, first add phosphoric acid, set the temperature at 300°C, microwave radiation heating for 30 minutes, and the temperature drops to 180°C Add melamine after ℃, set the reaction temperature to 260℃, feed dry ammonia during the reaction, heat, stir and knead under microwave radiation for 20 minutes, stop heating, and cool to obtain low water-soluble ammonium polyphosphate flame retardant products. However, it takes about 4 hours to synthesize low water-soluble ammonium polyphosphate by conventional heating.

Embodiment 3

[0035] The above equipment is used for the synthesis of ammonium polyphosphate flame retardant, ammonium polyphosphate flame retardant is synthesized with ammonium dihydrogen phosphate and melamine as raw materials, the microwave power is 500W, the reaction temperature is set at 250°C, and the microwave radiation is carried out without ammonia gas Heating, stirring and kneading under low temperature for 30 minutes, then stop heating and cooling, and cool to obtain a low water-soluble ammonium polyphosphate flame retardant product with balanced quality. During the reaction process, low water-soluble ammonium polyphosphate can also be synthesized without feeding ammonia gas. Conventional heating is difficult to solidify without feeding ammonia, and there are temperature gradients and bottle wall effects during the reaction process, which makes the quality of the synthesized products different.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com