Constant-temperature antibacterial, antiviral and antistatic multifunctional integrated fabric and processing technology

A processing technology and anti-static technology, which is applied in the field of textile manufacturing, can solve problems such as antibacterial, constant temperature, and anti-static, and achieve the effects of reducing human body heat loss, light and soft materials, and high specific strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be specifically described below in conjunction with the accompanying drawings and embodiments.

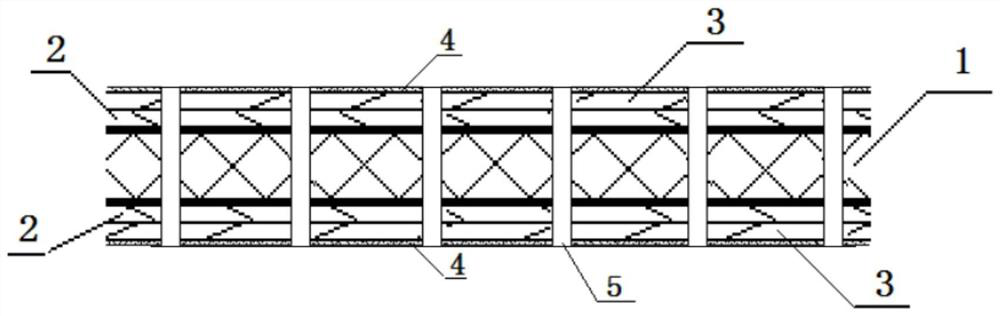

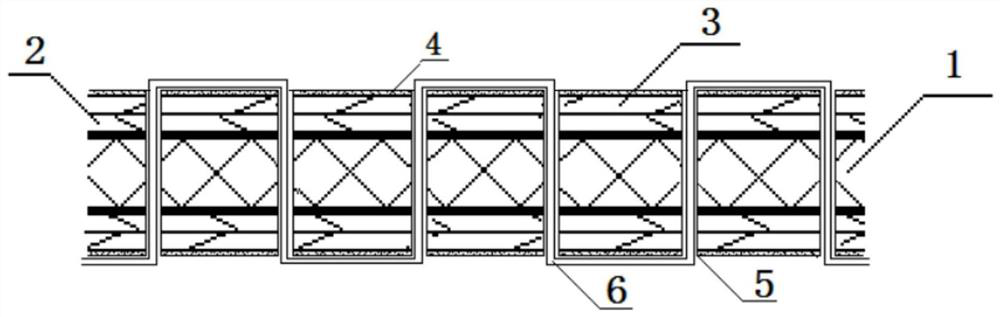

[0037] Such as Figure 1-Figure 3 As shown, the present invention uses special polymer fabrics as the substrate, modifies the surface, forms a variety of metal films with different components on the surface by physical vapor deposition, and uses the base fabric as the skeleton to form an integrated structure with antibacterial and constant temperature functions. composite material.

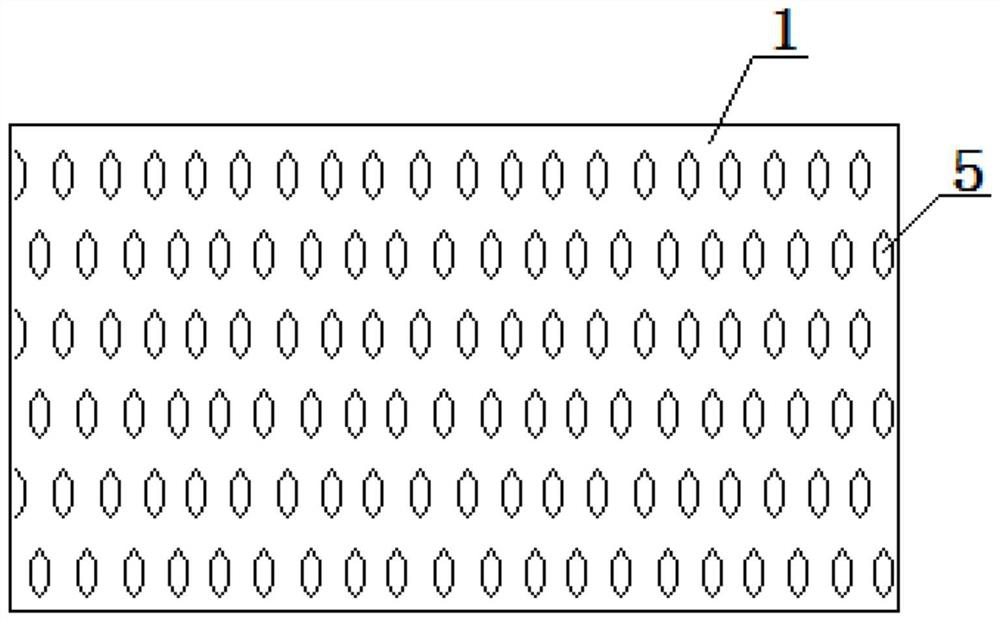

[0038] The present invention includes: base material 1: base material 1 is a high-strength and high-density fabric with diamond-shaped mesh 5; silver-plated layer 2: silver-plated layer 2 is covered on the upper and lower layers of base material 1; Set on the silver-plated layer 2; anti-oxidation layer 4: set outside the stainless steel layer 3;

[0039] The base material 1 is made of nylon 66 / nylon 6 filament coated spandex warp knitting.

[0040] The proportion of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com