Ore online sorting device and sorting method

A technology of ore and equipment, which is applied in the ore online sorting equipment and sorting field, can solve the problems of low photoelectric conversion efficiency and sensitivity, image contrast and definition limitation, and easy to be affected by scattering, so as to achieve high resolution accuracy and ray utilization The effect of improving efficiency, material identification ability, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings.

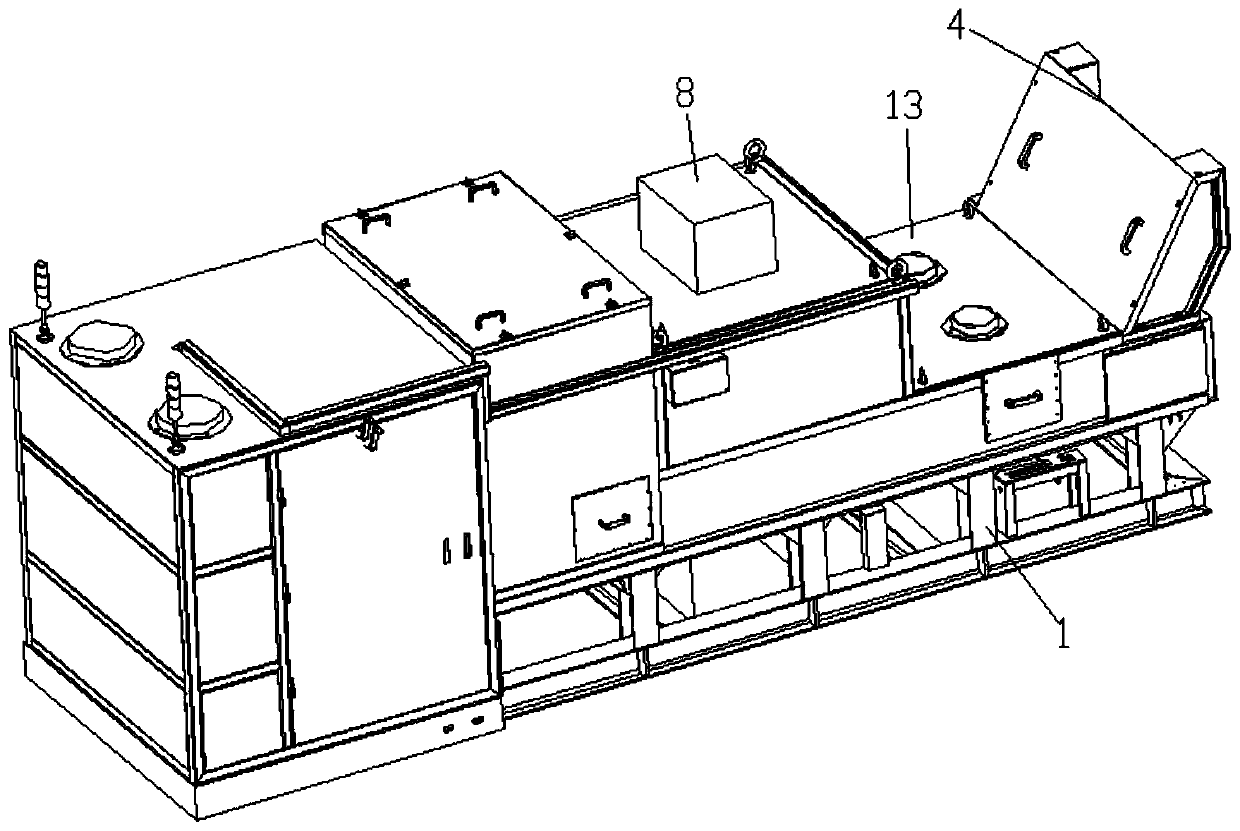

[0039] In one embodiment of the present invention, refer to Figure 3 to Figure 6 , provides a kind of ore on-line sorting equipment, comprises fuselage frame 1, is installed on the fuselage frame 1 and is positioned at its right side unloading chute 4, is positioned at its bottom belt type conveyance device 2, is positioned at its middle top The radiation source assembly 3, the radiation detector 5 located in the middle and opposite to the radiation source assembly 3, the pneumatic actuator 6 located on the top left side, the receiving bin 9 located at the bottom left side and the The control device 7 on the left is electrically connected to the belt conveyor 2, the radiation source assembly 3, the radiation detector 5 and the pneumatic actuator 6 respectively;

[0040] Specifically, the belt conveyor 2 includes two belt shafts 22, a belt 21 tensioned between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com