Welding gun with vibration cushioning function

A shock-absorbing and welding torch technology, applied in the field of welding guns with shock-absorbing function, can solve the problems of loss, damage to circuit board components, affecting the quality of circuit boards, etc., to achieve a stable center of gravity, ensure processing quality, and enhance versatility and flexibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

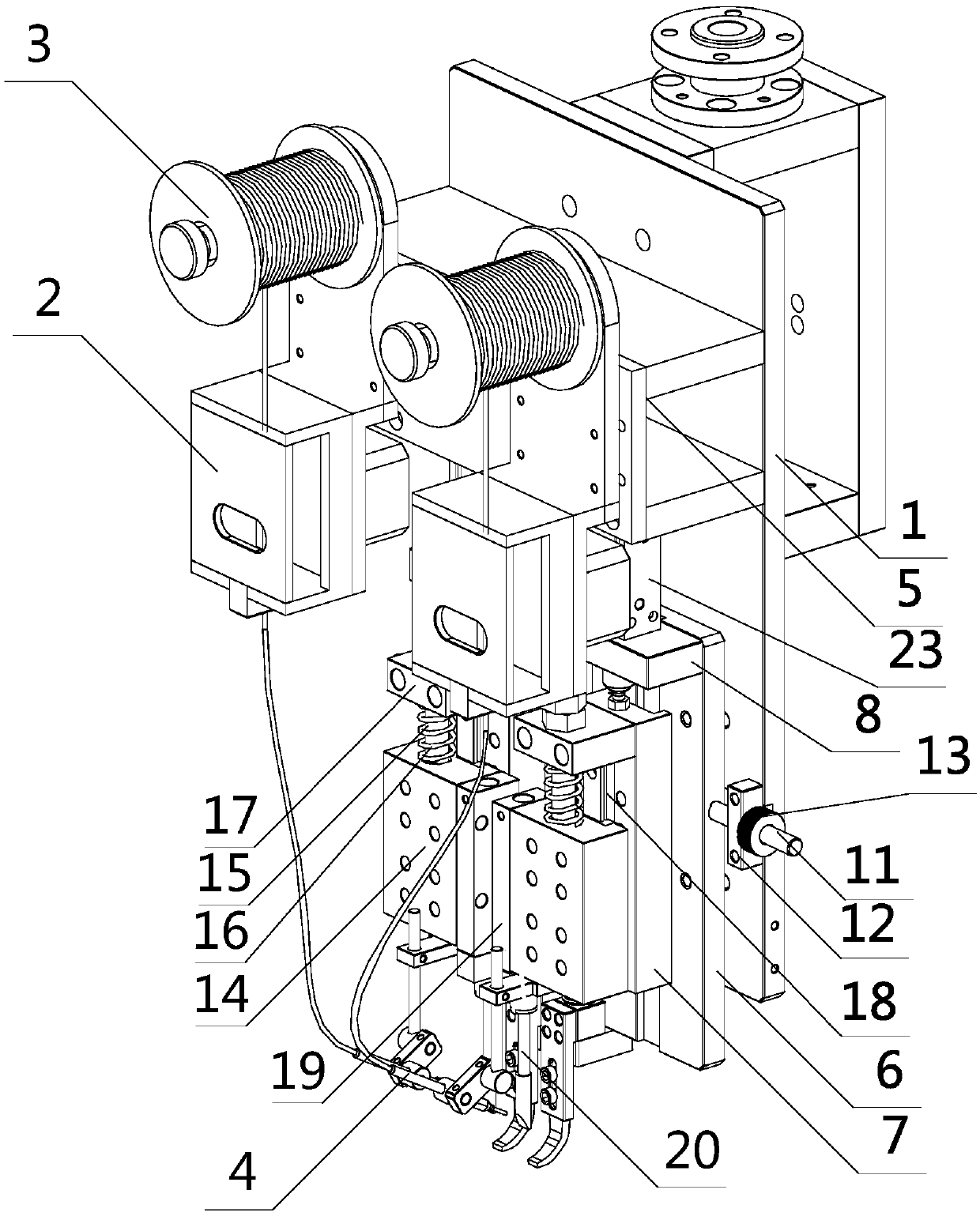

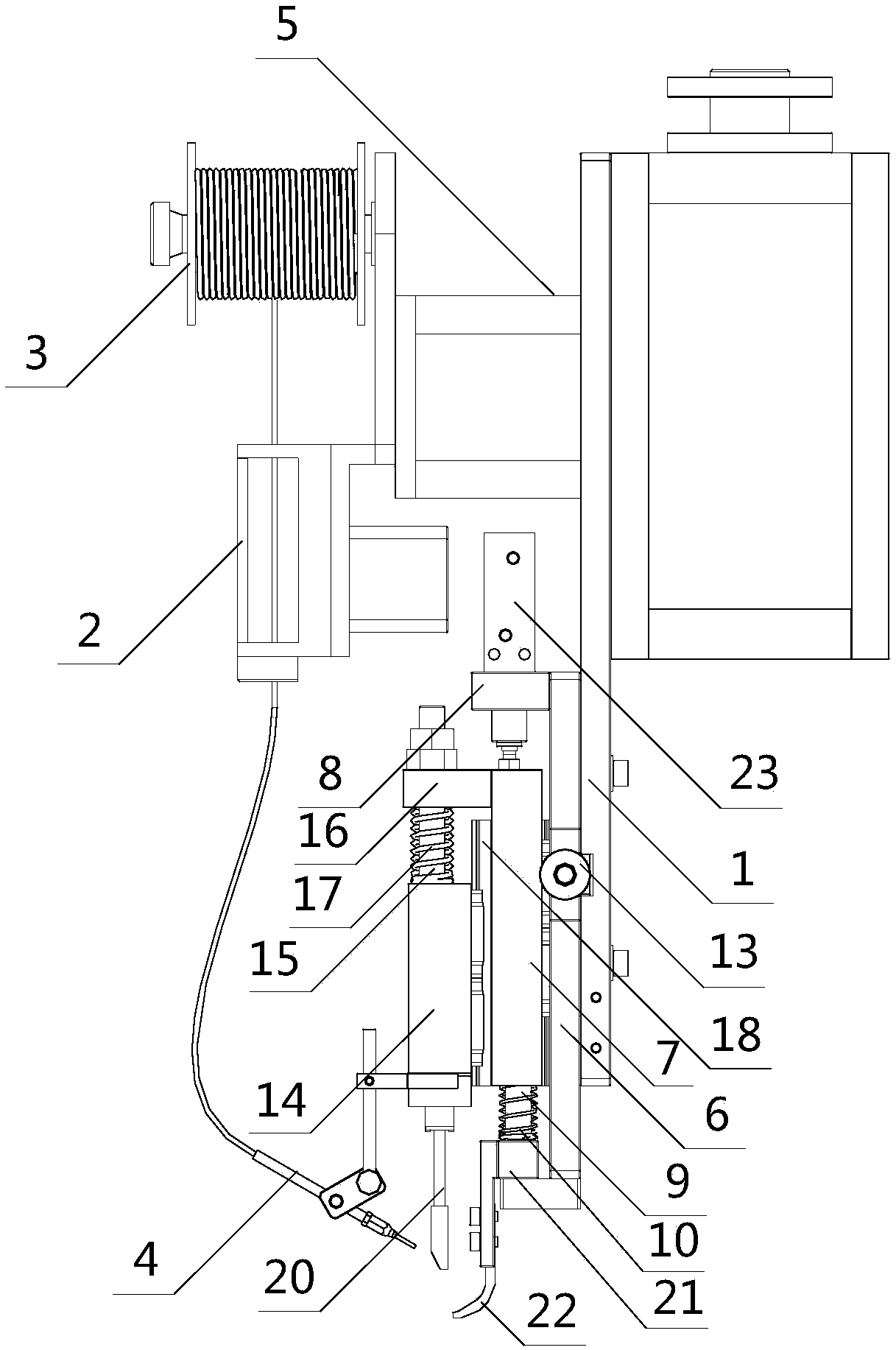

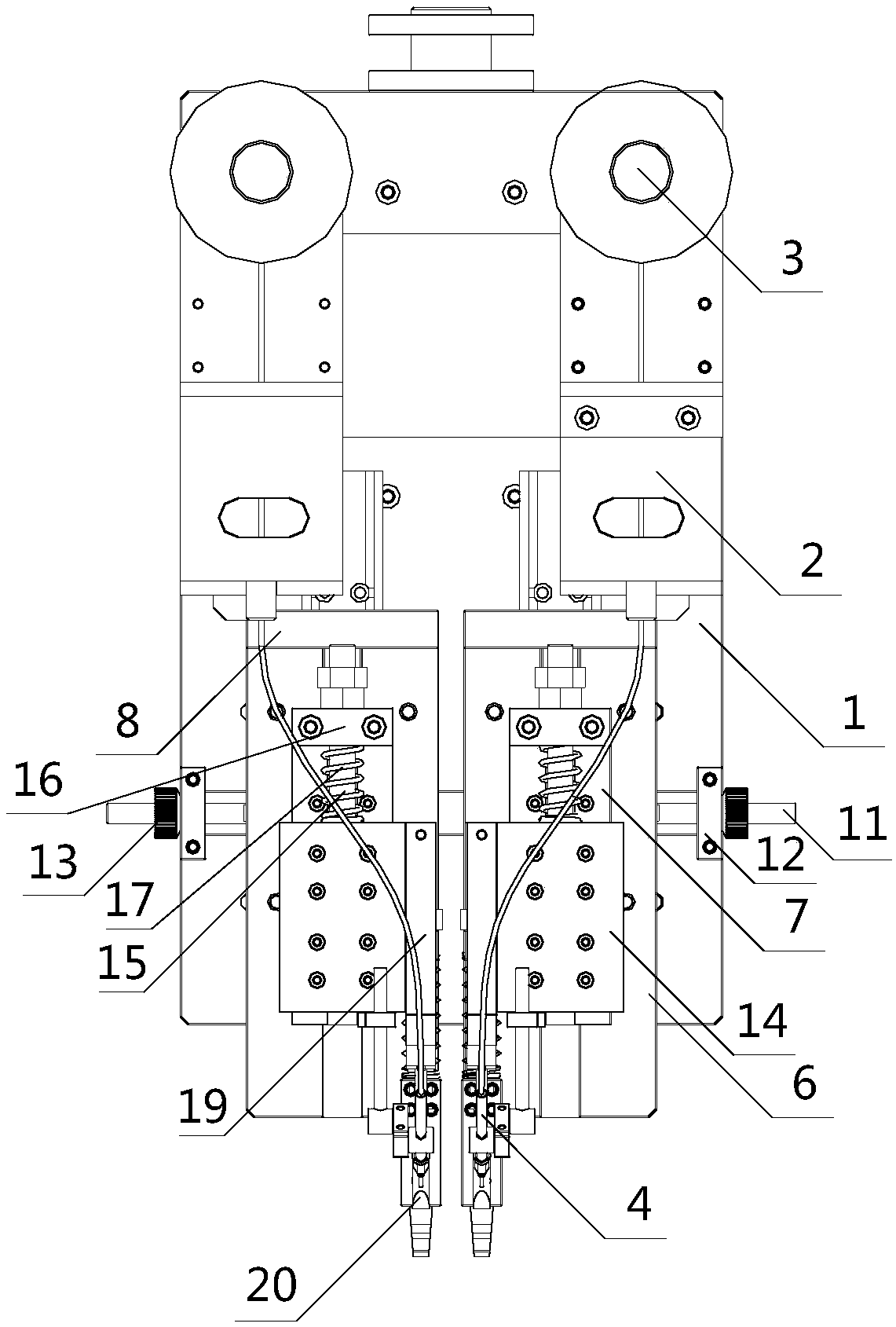

[0032] Such as Figure 1-3As shown, a welding torch with damping function includes a vertically arranged back plate 1 and at least one welding unit, the welding unit includes a welding assembly, a lifting movement assembly, a shock absorbing mechanism and a tin supply assembly, and the back plate 1 is fixed on the external mobile carrier, and can drive the welding assembly, lifting movement assembly, cushioning mechanism and tin supply assembly to move together with the external mobile carrier; the tin supply assembly, lifting movement assembly, cushioning mechanism and The soldering components are respectively arranged on the back plate 1, and the tin supplying components provide solder wires for the soldering comp...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap