Visual servo switching control method and system

A visual servo and control method technology, applied in the direction of program control manipulators, manufacturing tools, manipulators, etc., can solve the problems of poor system stability and anti-interference performance, inconvenient use, unstable saturation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

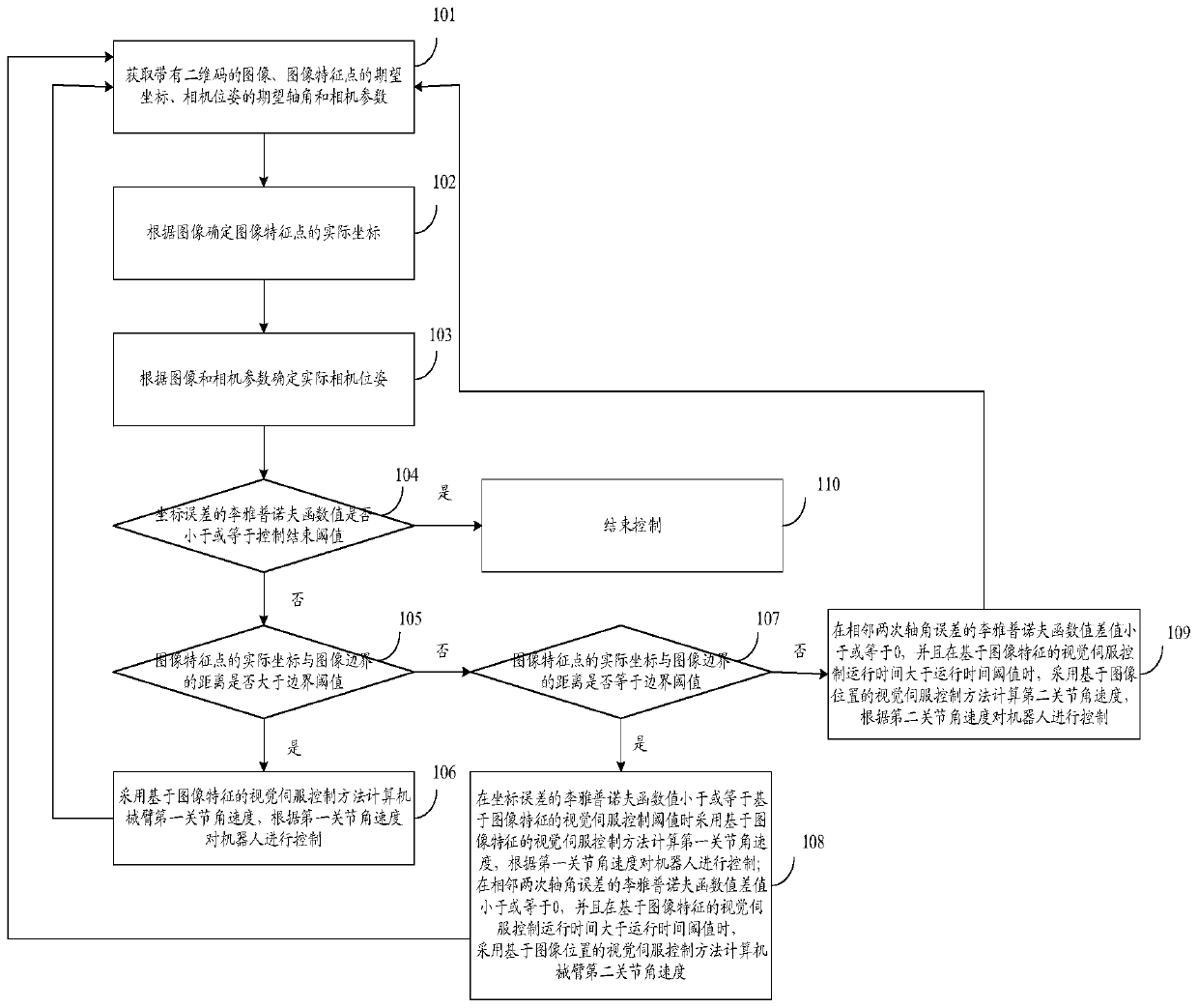

[0087] figure 1 It is a flow chart of the visual servo switching control method in the embodiment of the present invention, such as figure 1 As shown, a visual servo switching control method, including:

[0088] Step 101: Obtain an image with a two-dimensional code, expected coordinates of image feature points, expected axis angle of camera pose, and camera parameters. The image feature points are the corner points of the two-dimensional code.

[0089] Step 102: Determine the actual coordinates of the image feature points according to the image.

[0090] Step 103: Determine the actual camera pose according to the image and camera parameters.

[0091] Step 104: Judging whether the Lyapunov function value of the coordinate error is less than or equal to the control end threshold, and obtaining a first judging result. If the first judgment result is yes, execute step 110; if the first judgment result is no, execute step 105. The coordinate error is the error between the actu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com