Power battery power supply system for rail engineering vehicle

A rail engineering vehicle and power battery technology, which is applied in the direction of battery/fuel cell control devices, secondary batteries, battery pack components, etc., can solve the problems of inability to maintain vehicle operation, small load capacity, and energy density limitations, and achieve Improved operational flexibility, long running time, and guaranteed service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

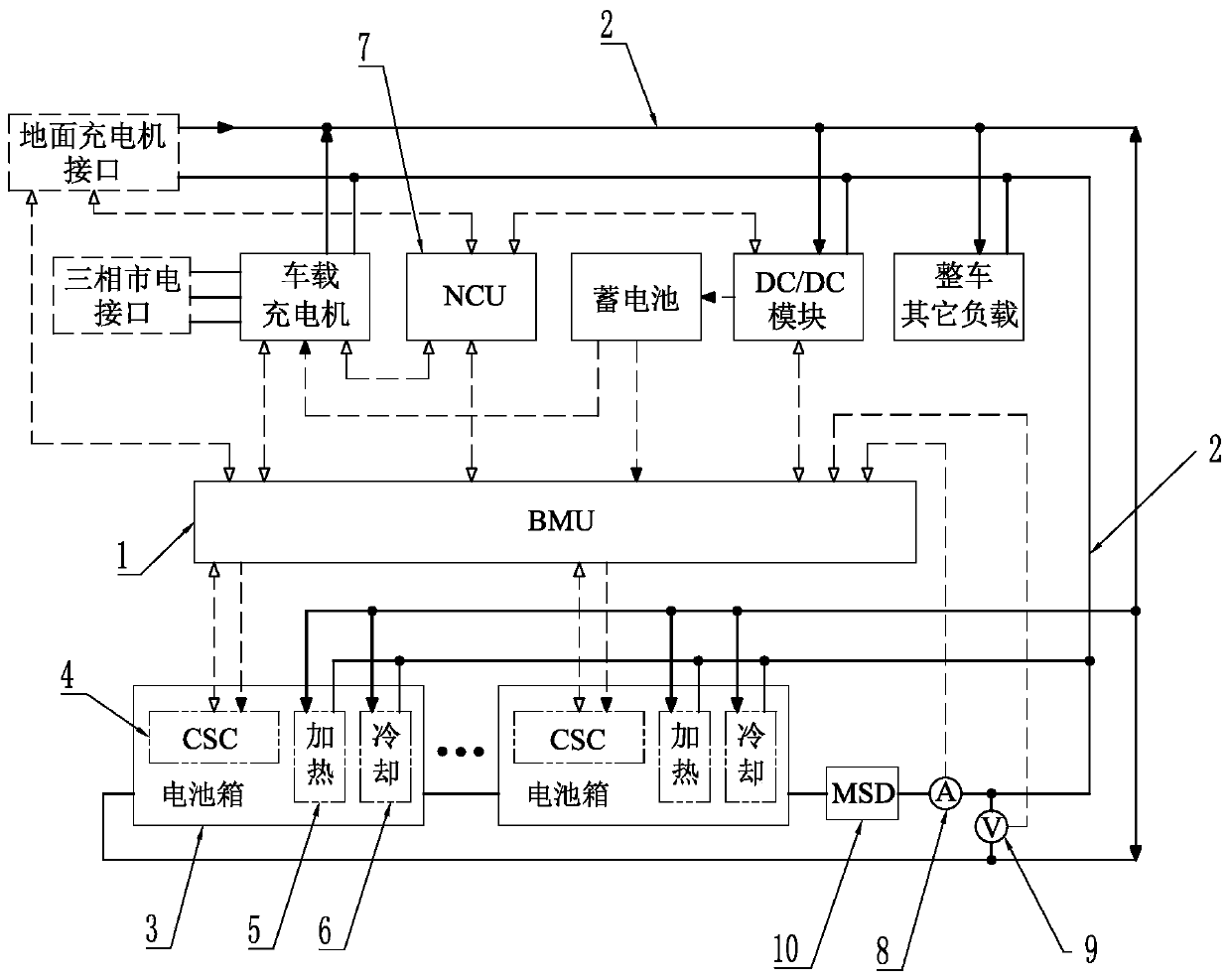

[0024] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0025] see figure 1 , a power battery power supply system for rail engineering vehicles in the present invention, including a battery box group composed of several battery boxes 3 connected in series or in parallel, the series connection of the battery boxes is used to increase the power supply voltage, and the batteries If the boxes are connected in parallel, the capacity can be expanded, so as to achieve the capacity and voltage required by the rail engineering vehicle; the battery box group is electrically connected to the high-voltage DC bus 2, which can obtain the DC power on the high-voltage DC bus when charging, and can also be used when discharging. To provide electric energy for other loads of the vehicle connected to the high-voltage DC bus, the high-voltage DC bus 2 is used as a high-voltage powe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com