Refining slag carbonation optimized geopolymer and preparation method thereof

A technology of geopolymer and refining slag, applied in cement production and other directions, can solve problems such as poor stability of raw materials, and achieve good mechanical properties and good structural compactness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

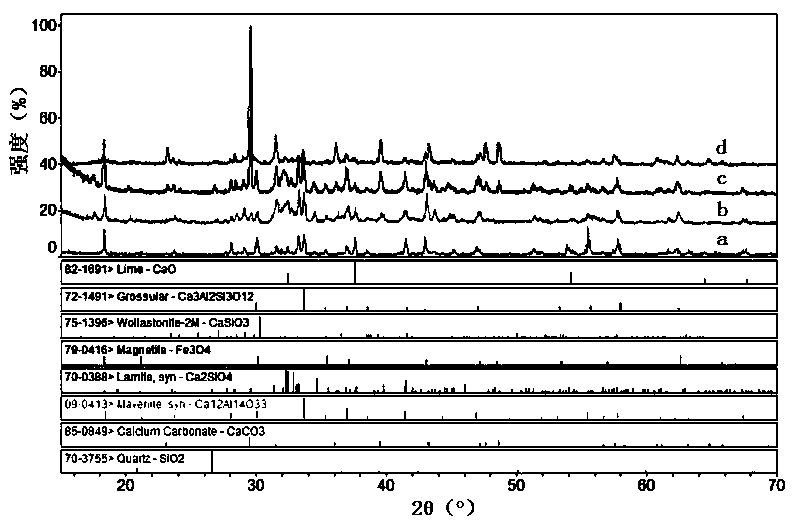

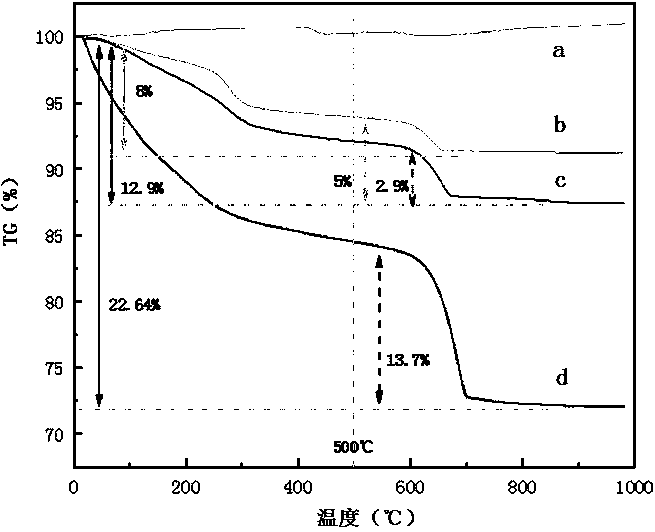

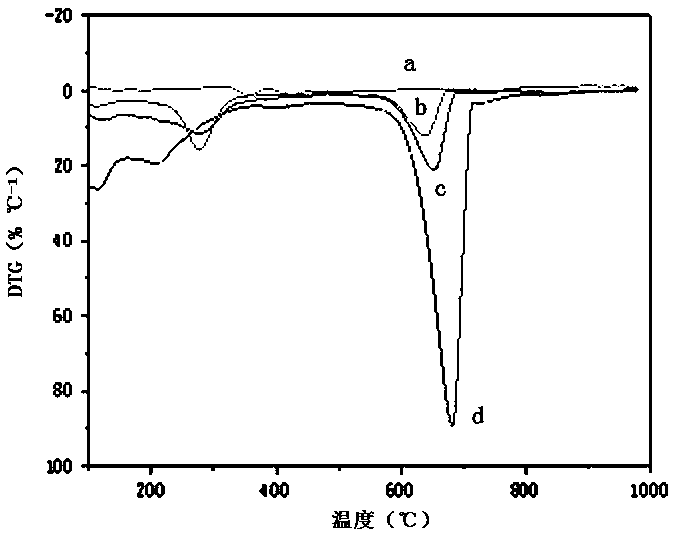

Image

Examples

Embodiment 1

[0037] Embodiment 1: The geopolymer optimized for carbonation of the refining slag is obtained according to the following steps: in the first step, the required amount of refining slag after grinding and sieving is mixed and stirred with water, and at the same time, CO 2 Carry out carbonation reaction to obtain carbonized refining slag slurry, wherein the weight ratio of refining slag to water is 1:4.5 to 5.5; the second step is to obtain carbonized refining slag slurry after solid-liquid separation and drying; third step , get the required amount of water glass, sodium hydroxide and water and mix and stir to obtain an alkaline liquid activator, wherein the water glass is 22 to 26 parts by weight, and the sodium hydroxide is 38 to 42 parts , water is 58 to 62 parts; the fourth step is to add the required amount of carbonized refining slag and fly ash to the alkaline liquid activator, mix and stir to obtain the geopolymer optimized for carbonation of refining slag, wherein, carb...

Embodiment 2

[0039] Embodiment 2: The geopolymer optimized for carbonation of the refining slag is obtained according to the following steps: in the first step, the required amount of refining slag after grinding and sieving is mixed and stirred with water, and at the same time, CO 2Carry out carbonation reaction to obtain carbonized refining slag slurry, wherein the weight ratio of refining slag to water is 1:4.5 or 5.5; the second step is to obtain carbonized refining slag slurry after solid-liquid separation and drying; third step , get the required amount of water glass, sodium hydroxide and water and mix and stir to obtain an alkaline liquid activator, wherein the water glass is 22 or 26 parts by weight, and the sodium hydroxide is 38 or 42 parts , water is 58 parts or 62 parts; the fourth step is to add the required amount of carbonized refining slag and fly ash to the alkaline liquid activator, mix and stir to obtain the geopolymer optimized for carbonation of refining slag, wherein,...

Embodiment 3

[0040] Embodiment 3: As an optimization of the above embodiment, in the first step, the particle size of the refining slag is 38 μm to 88 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com