Super heavy oil SAGD exploitation method

A mining method and ultra-heavy oil technology, which is applied in the fields of extraction fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of low crude oil extraction efficiency and low oil-gas ratio of crude oil, etc., so as to improve the production quality and oil The steam ratio and the effect of improving mining efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

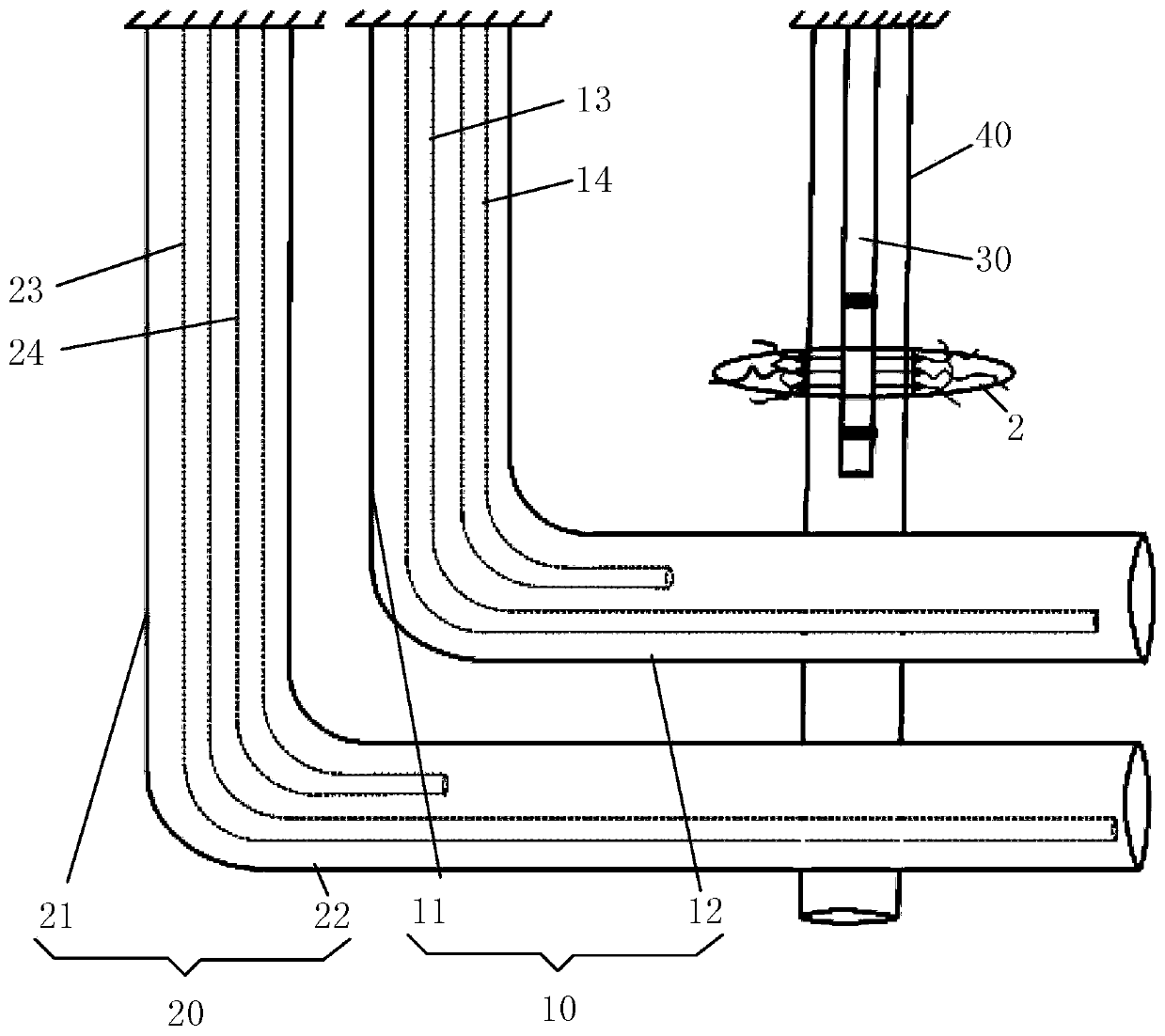

[0025] exist figure 1 In the optional embodiment shown, the super heavy oil SAGD recovery method includes the following steps:

[0026] Step S10, the SAGD super-heavy oil recovery method provided by this application adopts the well layout method of parallel double horizontal wells, and the steam injection well 10 and the production well 20 are set, and the steam injection well 10 and the production well 20 are both extended to the super-heavy oil reservoir .

[0027] Optionally, in step S10, the steam injection well 10 includes a vertical steam injection well section 11 and a horizontal steam injection well section 12, and the production well 20 includes a vertical production well section 21 and a horizontal production well section 22, and the horizontal steam injection well section Section 12 is closer to the surface relative to horizontal production well section 22 .

[0028] Step S11 , setting a plurality of observation wells extending along the vertical direction and arr...

Embodiment 2

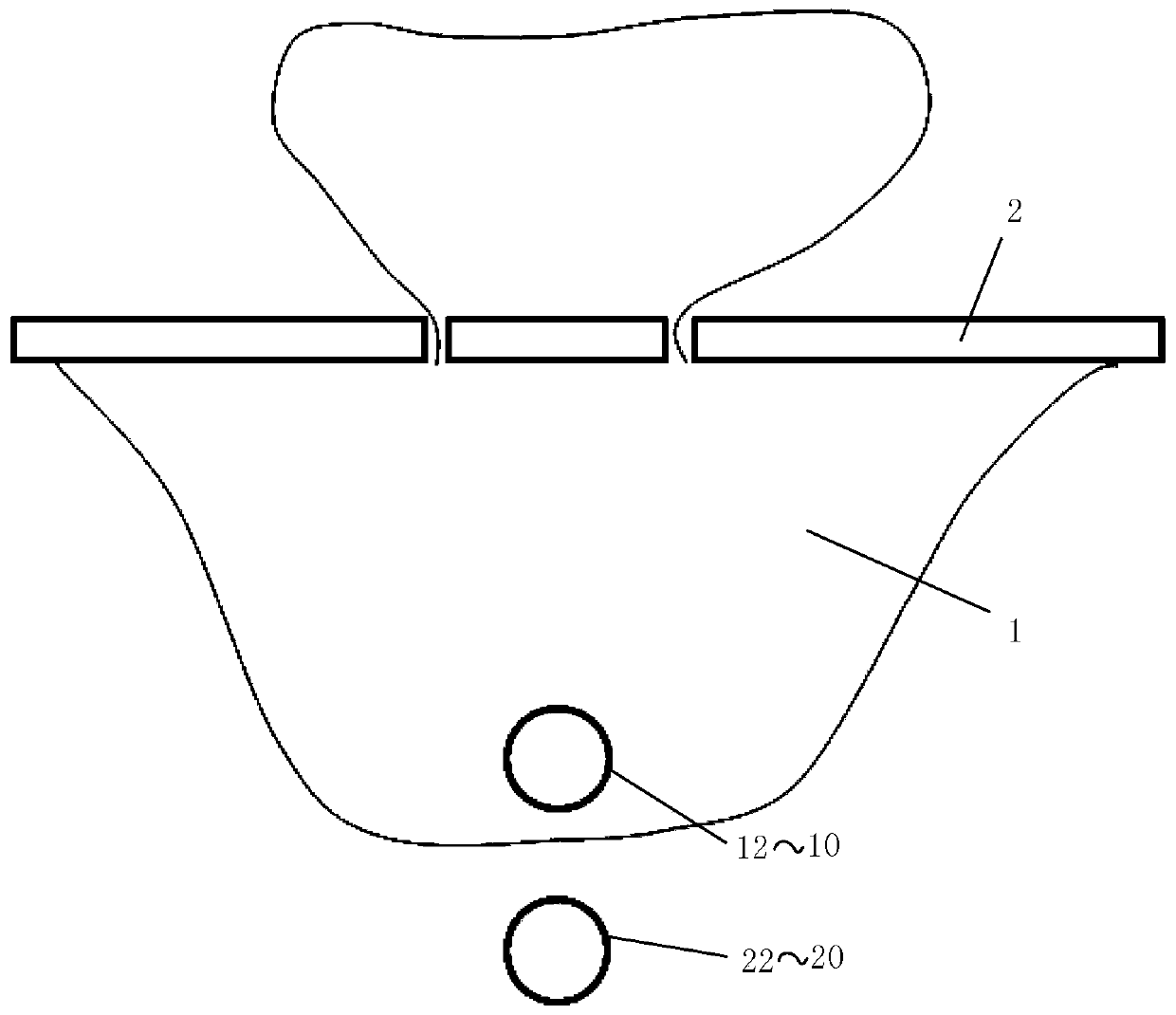

[0052] The difference between Embodiment 2 and Embodiment 1 is that the super-heavy oil SAGD production method also includes step S60, real-time monitoring of the pressure at the wellhead of the steam injection well 10 located in the super-heavy oil reservoir, when the pressure drops to the set value , the injection tool 30 is proposed from the tool lowering well 40, the pipe string originally arranged in the observation well 40 as the tool lowering well 40 is lowered into the observation well, and the inlet is replaced with a thermal recovery wellhead, and then passed through the lowering well 40 as the tool Observation wells for super-heavy oil reservoirs are injected with steam.

[0053] Under the condition that the amount of steam injected into the super-heavy oil reservoir through the steam injection well 10 remains unchanged, when the injection tool 30 sprays the interlayer 2 to cause cracks to appear in the interlayer 2, the steam injection well 10 located in the super-h...

Embodiment 3

[0059] The difference between the third embodiment and the first embodiment is that, in the case where the observation well cannot be used as the tool lowering well 40, in step S30, a construction well is dug on the ground as the tool lowering well 40, and the tool lowering well 40 is controlled by the ground. Extend vertically and pass through the interlayer 2. In this way, the versatility of the SAGD super-heavy oil recovery method can be improved, so that it can be applied to reservoirs in different environments.

[0060] In the third embodiment, the excavated construction well is used as the tool lowering well 40, and the injection tool 30 is extended to the position of the interlayer 2 through the tool lowering well 40, and the interlayer 2 is sprayed so that the steam chamber 1 can break through the interlayer 2, The upward expansion speed of the steam chamber 1 is accelerated, and the purpose of uniformly heating the super heavy oil reservoir and increasing the producti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com