Coal caving method based on coal seam geographic information system

A geographic information system and coal seam technology, applied in ground mining, earth square drilling, underground mining, etc., to achieve the effect of simple thinking, reliable operation, and strong application adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

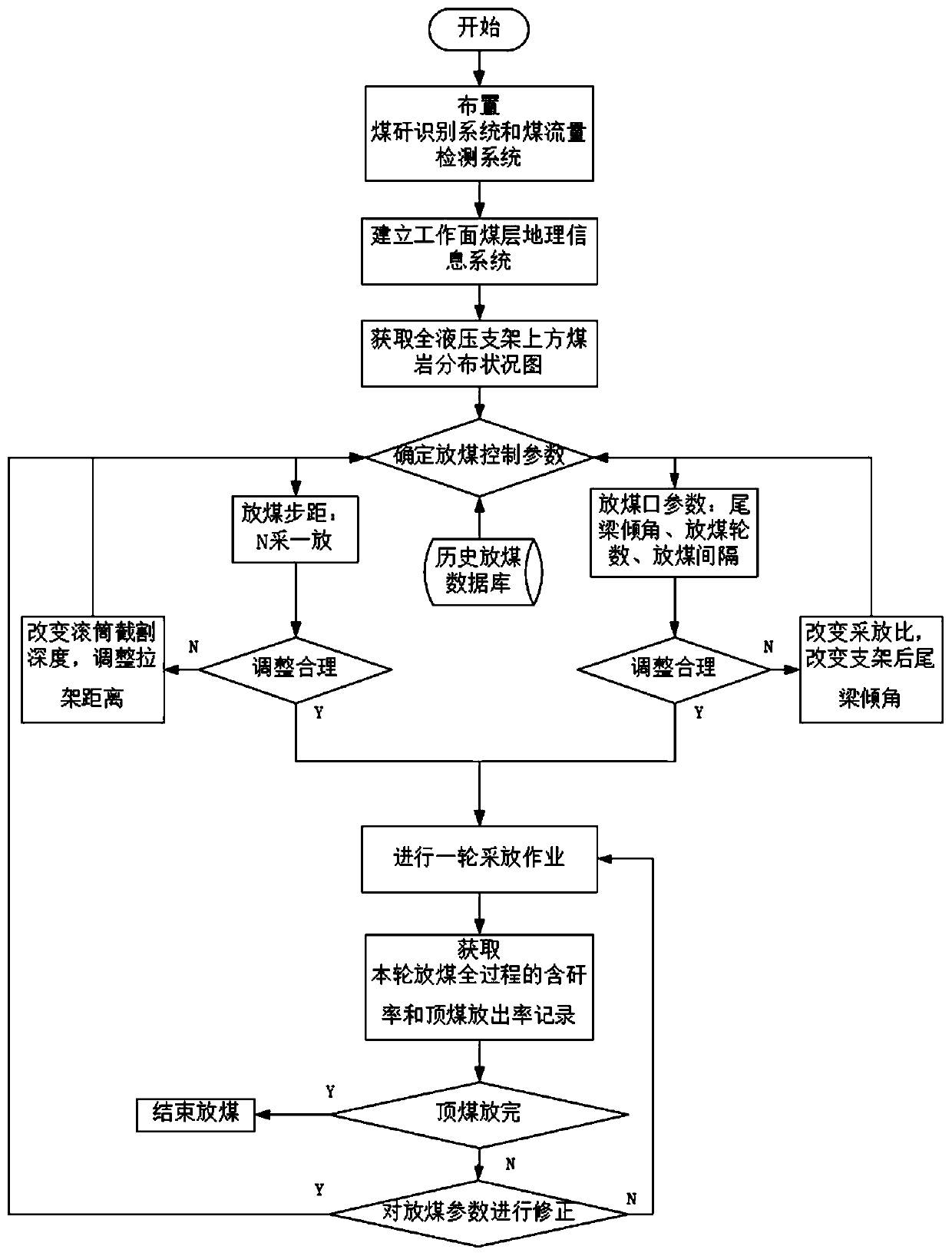

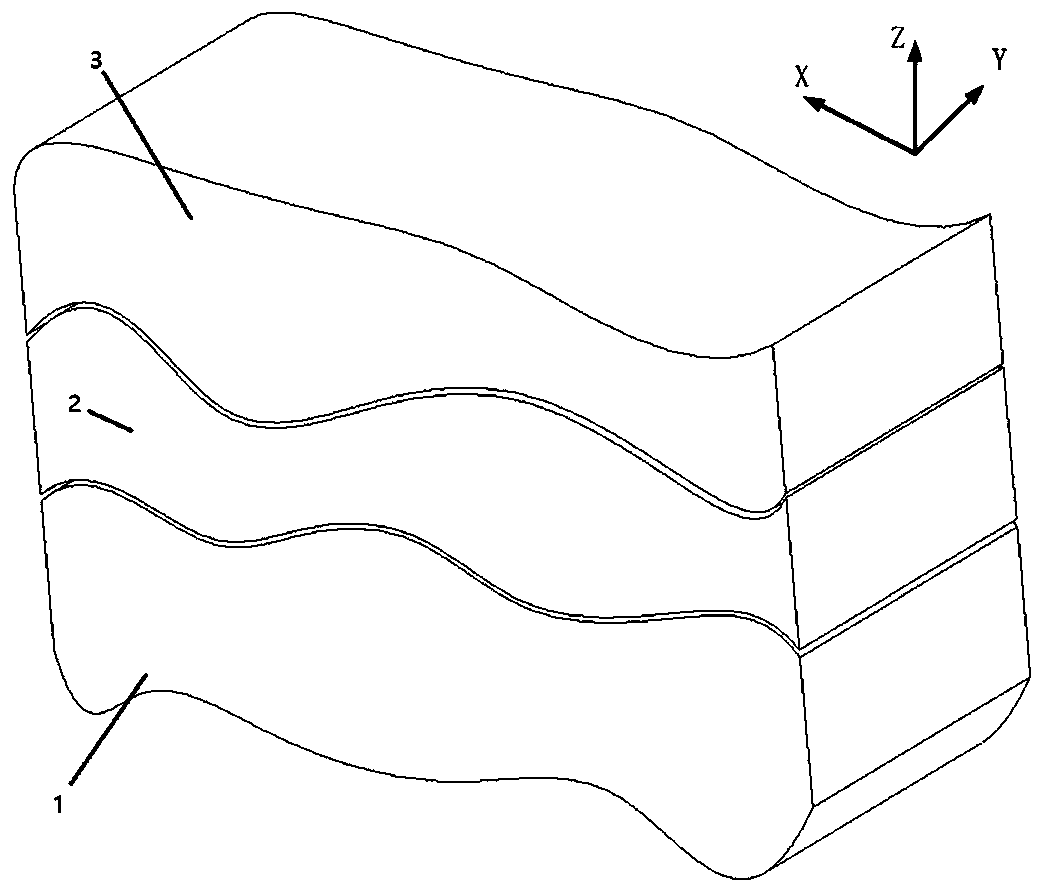

[0021] According to the method of setting coal based on the coal seam geographic information system described in the present invention, the relationship among technical parameters, positions and processes of the shearer, the hydraulic support for caving coal and the scraper conveyor is established; based on this relationship, the coal mining method is established The correlation model of the cutting depth of the machine drum, the distance of the scraper and the attitude of the rear tail beam of the hydraulic support is used to construct the working face space with the control parameters of the coal discharge step distance and the coal discharge port parameters by using the established data of the coal seam geographic information system of the working face The coal flow control method, according to the positioning technology of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com