High-efficiency supercharged zero-clearance ionic liquid compressor with precise and adjustable piston stroke

A technology of piston stroke and ionic liquid, which is applied in the field of compressors, can solve the problems of restricting the construction and development of hydrogen refueling stations, complicated structure, and high cost, and achieve the effect of simple structure, good repeatability, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

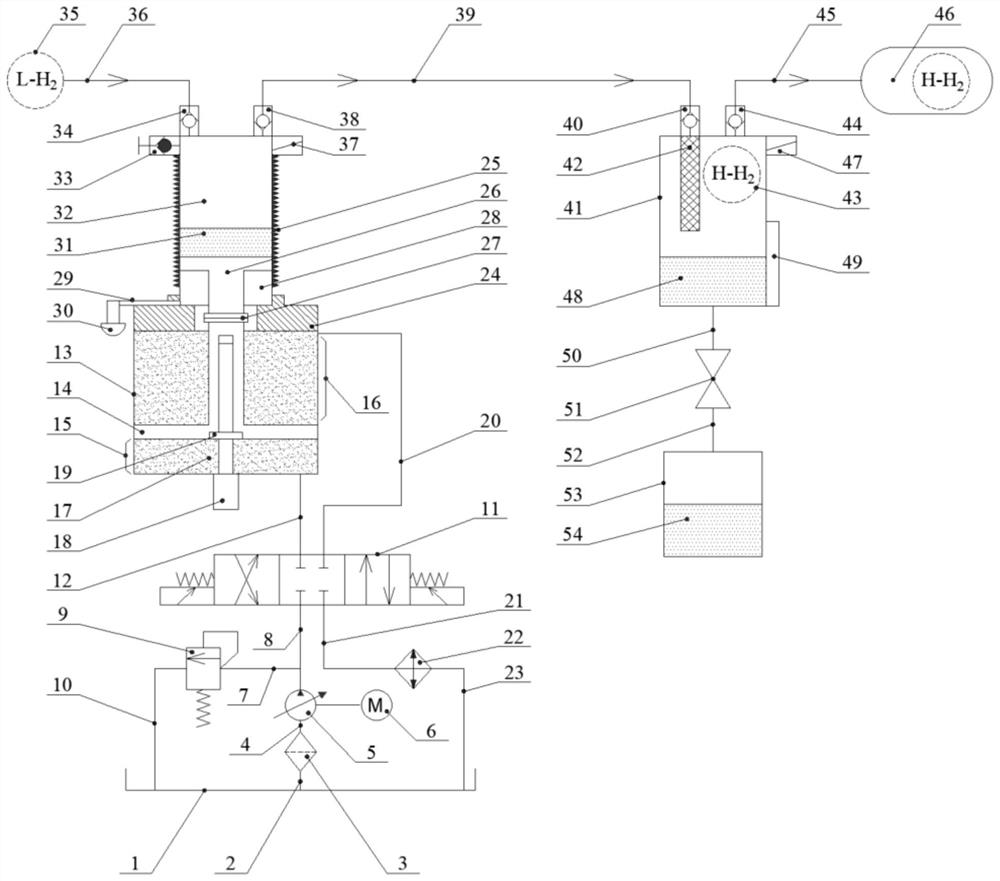

[0049] refer to figure 1 , a high-efficiency supercharged zero-backlash ionic liquid compressor with precise and adjustable piston strokes, including a hydraulic oil tank 1, a first hydraulic pipeline 2 connected to the hydraulic oil tank 1, a hydraulic filter 3 connected to the first hydraulic pipeline 2, and a hydraulic oil tank 1 connected to the hydraulic oil tank 1. The filter 3 is connected to the inlet oil circuit of the hydraulic pump 5 after passing through the second hydraulic pipeline 4. The servo motor 6 is installed on the hydraulic pump 5, and the outlet oil circuit of the hydraulic pump 5 is respectively connected to the third hydraulic pipeline 7 and the fourth hydraulic pipeline. 8. The third hydraulic pipeline 7 is connected to the relief valve 9 , and the relief valve 9 is connected to the hydraulic oil tank 1 after passing through the fifth hydraulic pipeline 10 . The fourth hydraulic pipeline 8 is connected to the three-position four-way electromagnetic pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com