Method for testing surface tension and wettability parameters of high-temperature liquid asphalt

A technology of surface tension and liquid asphalt, applied in surface tension analysis, surface/boundary effects, measurement devices, etc., can solve the problems of high cost of test equipment, large influence of experimental results, and error of inner radius measurement value, etc., and achieve the test cost. The effect of low, strong operability, and improved precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

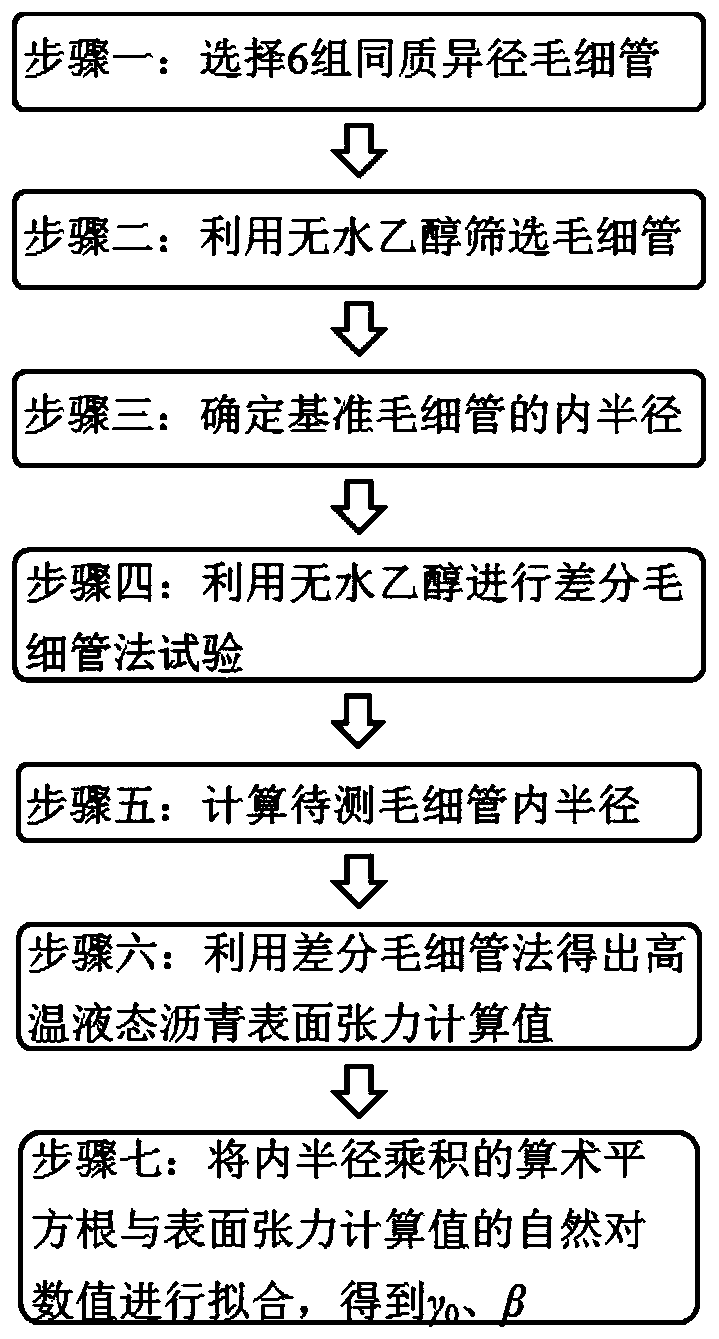

[0050] Such as figure 1 The test procedures for the surface tension and wettability parameters of the bitumen shown are further detailed through the test steps and test results of the surface tension and wettability parameters of No. 70 base asphalt at 135°C:

[0051] Step 1. Select 6 groups of homogeneous and different-diameter capillaries, among which the production labels of the inner radius of the capillary selected from 1 to 5 groups are: 0.1mm, 0.15mm, 0.2mm, 0.25mm, 0.5mm, and the sixth group is used as the inner radius calibration Reference pipe, the inner radius of the capillary is 1.0mm;

[0052] Step 2: Use absolute ethanol to clean and dry the capillary, and use the "compensation method" to immerse the capillary in absolute ethanol (the size of the liquid surface is 245mm×50mm, and the capillary is parallel to the long The position of the center line of the liquid surface on the side), until the liquid in the tube rises and stabilizes, each group screens out capil...

Embodiment 2

[0068] According to the scheme proposed in the present invention, according to the steps in Example 1, No. 70 base asphalt and No. 70 warm-mix asphalt (test temperature: 135 ° C), SBS modified asphalt and SBS modified warm-mix asphalt (test temperature: 165 °C) to test the surface tension and wettability parameters, the test results are shown in Table 4.

[0069] Table 4 Test results of surface tension and wettability parameters

[0070]

[0071]

[0072] According to the working principle of surfactants, within a certain dosage range, with the increase of the dosage of warm mix agent, the surface tension of surface active warm mix asphalt will gradually decrease, and the wettability will increase. It can be seen from Table 4 that after adding warm mix agent, the surface tension of asphalt decreases, and the wettability parameters increase, and with the increase of warm mix agent content, the surface tension of asphalt shows a significant decline trend, and the wettabili...

Embodiment 3

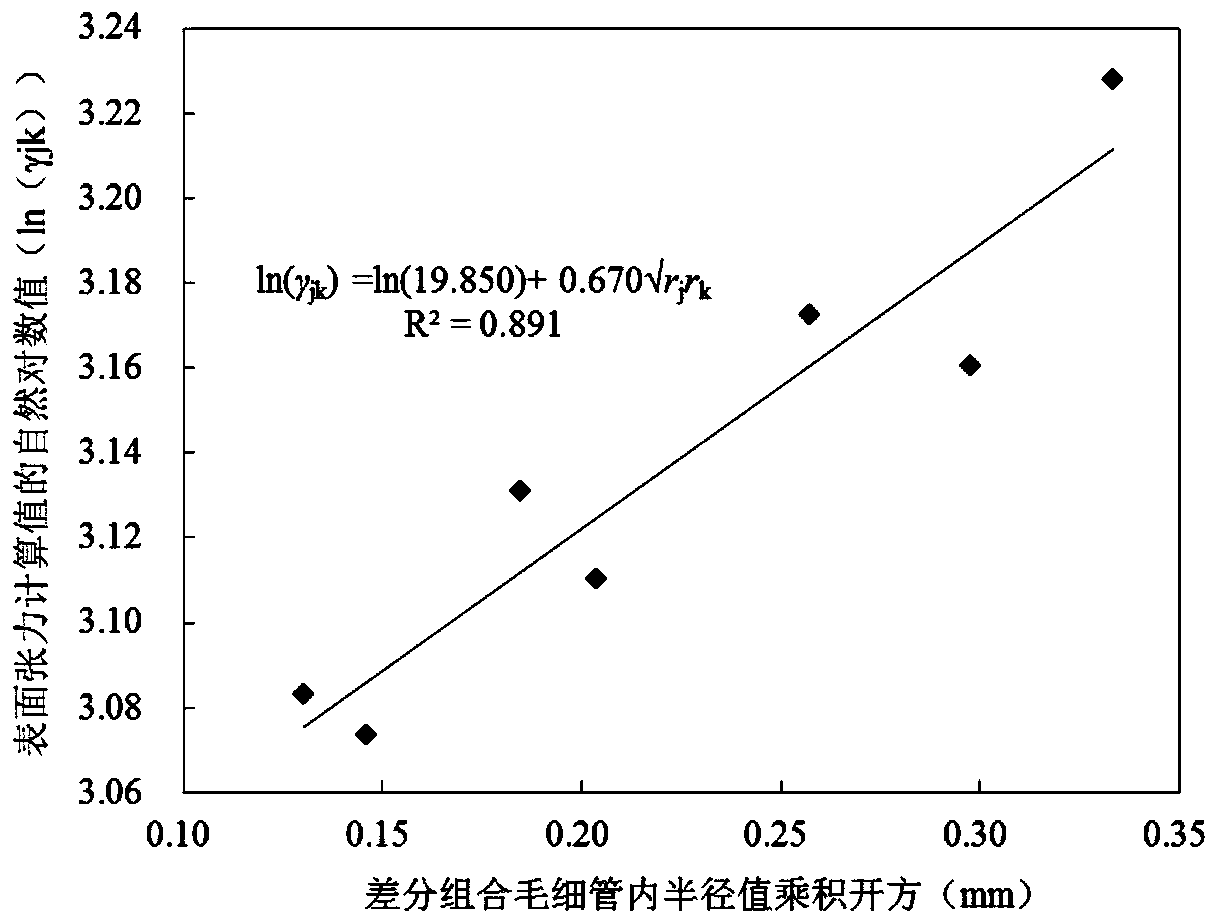

[0074] According to the solution proposed by the present invention, the surface tension precision is increased by about 26% to 54%. Combining with the traditional differential capillary method, the improvement of the surface tension precision of the present invention will be further described in detail. Using the scheme proposed by the present invention and the traditional differential capillary method respectively, test according to the steps in Example 1, test No. 70 base asphalt and No. 70 warm mix asphalt, SBS modified asphalt and SBS modified warm mix asphalt, test The results are shown in Table 5. Among them, the traditional differential capillary method test ignores the inner radius reverse calibration process and the impact of the contact angle on the test results, so the inner radius takes the value given by the production label, referring to the method of the Hunan Academy of Communications, and the inner radius is selected with a difference of 2 The capillary differ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com