Health management method and system for intelligent manufacturing equipment

A health management system and intelligent manufacturing technology, applied in manufacturing computing systems, data processing applications, electrical digital data processing, etc., can solve problems such as large economic losses, threats to the life safety of workers, hidden dangers, etc., to save costs, avoid Personal injury and difficulty reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

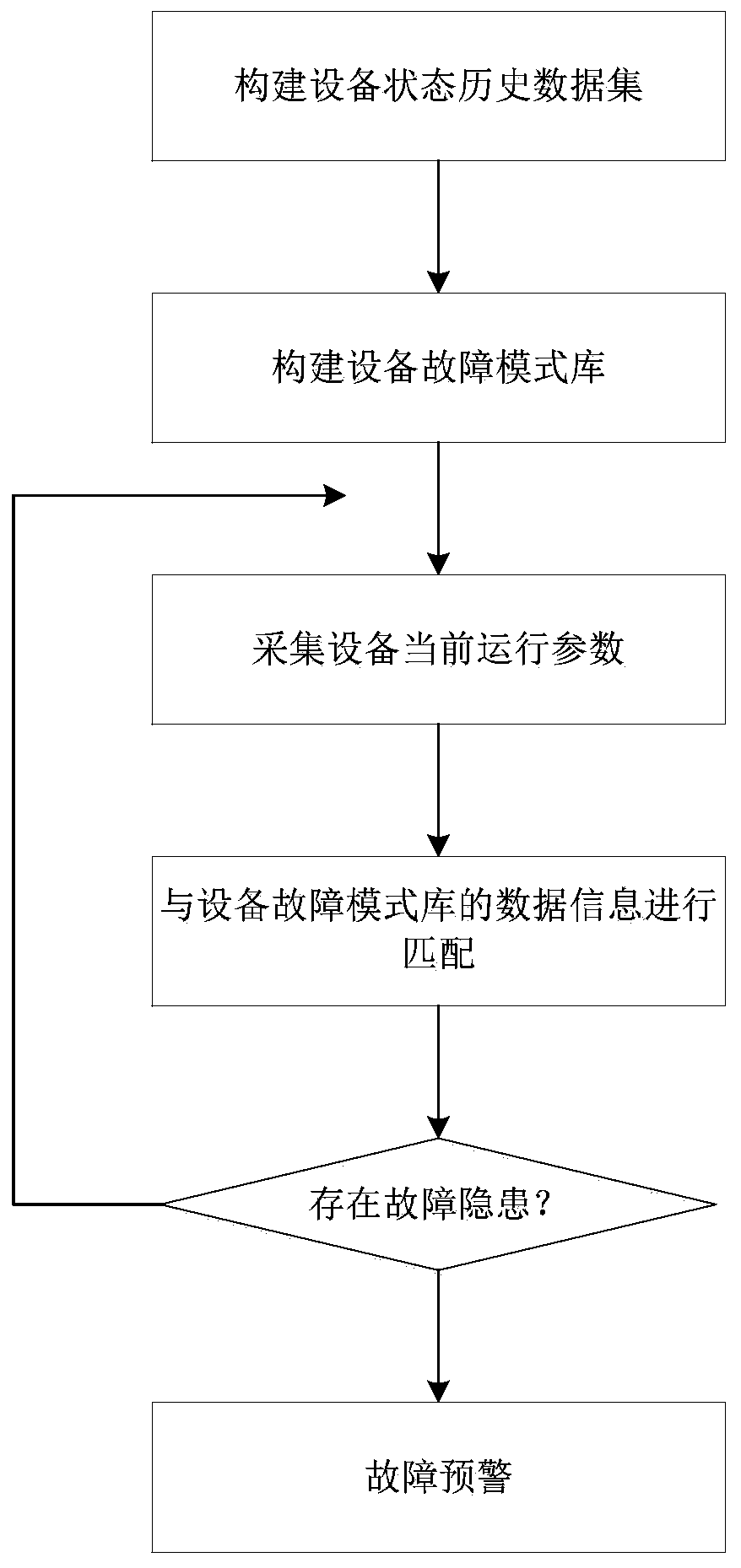

[0041] This embodiment provides a health management method for intelligent manufacturing equipment, such as figure 1 shown, including:

[0042] Step 1. Collect historical operating parameters of intelligent manufacturing equipment under normal conditions, and construct a historical data set of equipment status.

[0043] In this embodiment, in the early stage, the historical operating parameters of the intelligent manufacturing equipment in the normal state are collected through the data acquisition device installed on the large-scale intelligent manufacturing equipment. Preprocessing, constructing equipment status historical data set.

[0044] The historical operating parameters collected in this embodiment include vibration parameters, noise parameters, temperature parameters, humidity parameters, voltage parameters, current parameters and power parameters of large intelligent manufacturing equipment. The data acquisition devices involved include vibration sensors, noise se...

Embodiment 2

[0065] This embodiment provides a health management system for intelligent manufacturing equipment, including a historical data collection module, a fault mode construction module, a current data collection module and a fault evaluation module.

[0066] The historical data collection module is used to collect historical operating parameters of intelligent manufacturing equipment under normal conditions, and construct a historical data set of equipment status.

[0067] The failure mode construction module is used for performing correlation analysis on the equipment state historical data set, and constructing an equipment failure mode library.

[0068] The current data collection module is used for real-time collection of current operating parameters during the operation of the intelligent manufacturing equipment.

[0069] The state evaluation module is used to match the preprocessed current operating parameters with the data information of the equipment failure mode library, ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com