Positive electrode material as well as preparation method and application thereof

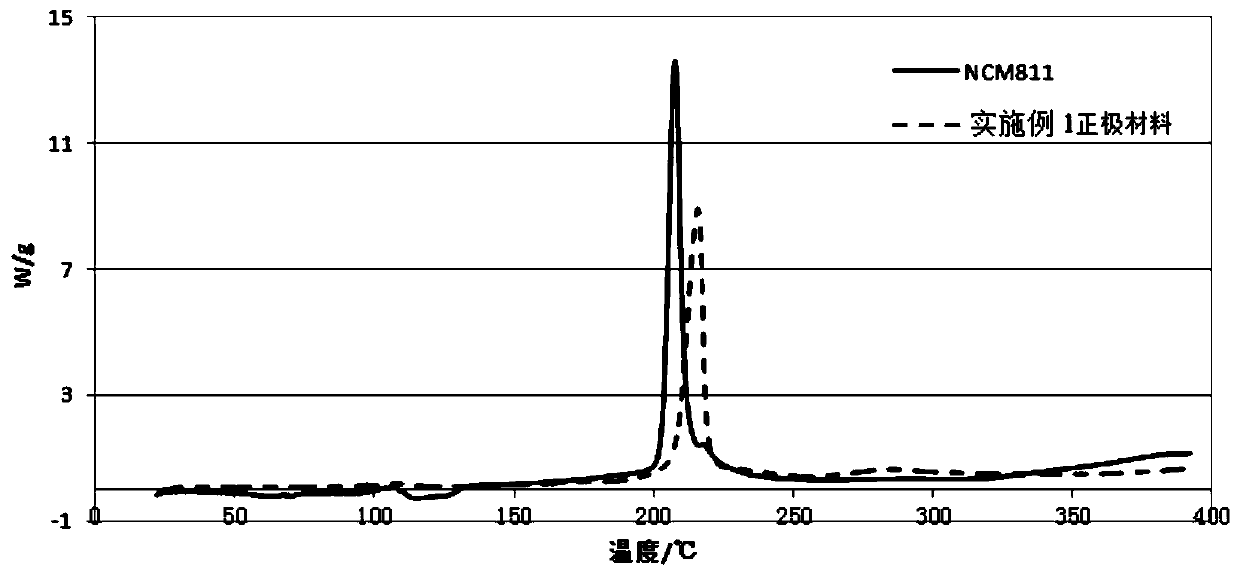

A positive electrode material and crystal technology, applied in the field of chemical power sources, can solve the problems of reduced structural stability, unreachable, and reduced cycle life of high-nickel materials, and achieve the effects of improving structural stability, stabilizing the positive electrode structure, and improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The preparation of the above positive electrode material may include the following steps: a step of preparing a precursor and a step of sintering. First, a precursor containing Ni, Co and Mn is formed, and then the precursor is mixed and sintered with a lithium source compound to obtain a positive electrode material. Specifically, the preparation method of the positive electrode material includes: adjusting the pH value of the solution containing nickel ions, manganese ions and cobalt ions to 10-12 under stirring conditions, and aging at 50-90°C for 5-12h after the reaction is completed , to obtain the precursor after separation, washing and drying. Then a sintering step is performed, mixing the lithium source compound and the obtained precursor uniformly, and sintering at 600° C.-1000° C. for 6-15 hours.

[0020] In a preferred embodiment, the precursor may be a carbonate or a hydroxide.

[0021] In a preferred embodiment, the lithium source compound can be LiOH·H 2...

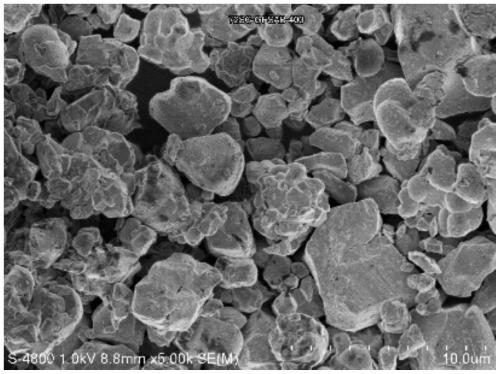

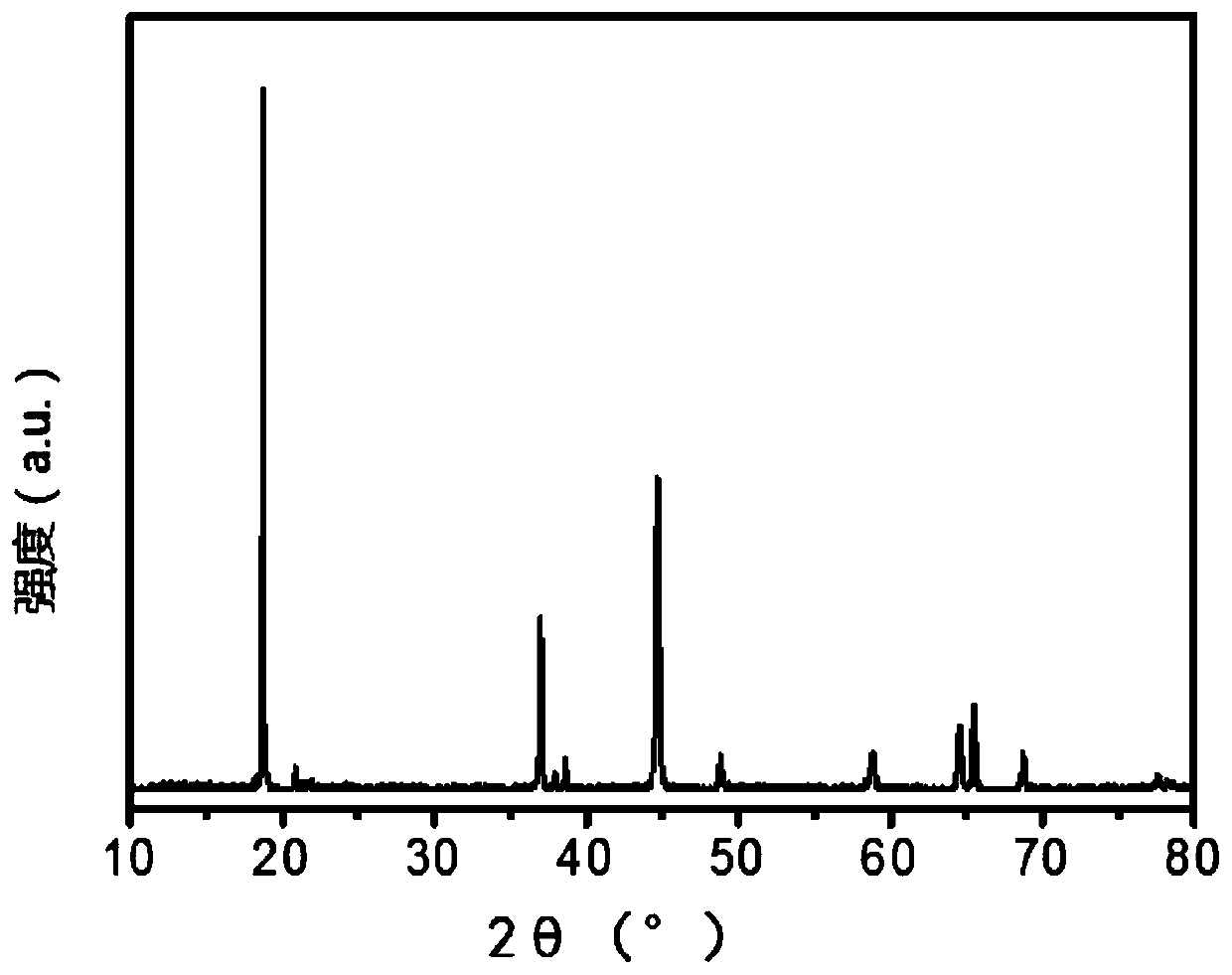

Embodiment 1

[0028] Pass a certain volume of nickel sulfate, cobalt, manganese solution and excess 2% molar sodium hydroxide solution through a peristaltic pump at 580 μL min -1 The feed rate is added dropwise to the mother liquor. The molar ratio of nickel, cobalt and manganese is listed as 72:9:19, the reaction temperature of the material is 50°C, the pH is controlled at 10, and at the same time the top stirring rod is set at 400rmp·min -1 Stir vigorously at a rotating speed of 100°C, and nitrogen protection is added during the reaction. After aging for 10 hours, the obtained hydroxide precursor was suction-filtered, washed twice with a certain volume of distilled water, and finally dried in vacuum at 100° C. for 6 hours to obtain a dry precursor. The precursor was thoroughly ground and mixed with a certain molar ratio of LiOH, and then heated in a muffle furnace at 5 °C min -1 The heating rate was pre-calcined at 500°C for 5h, and then calcined at 800°C for 12h to obtain the lithium-r...

Embodiment 2

[0033]Pass a certain volume of nickel acetate, cobalt, manganese solution and excess 3% mole sodium carbonate solution through a peristaltic pump at 1000 μL min -1 The feed rate is added dropwise to the mother liquor containing sodium carbonate. The molar ratio of nickel, cobalt, and manganese is listed as 76:9.5:14.5, the reaction temperature of the material is 55°C, pH=11, and the top stirring rod is set at 500rmp·min -1 Stir vigorously at a rotating speed of 100°C, and add argon protection during the reaction. The carbonate precursor obtained after aging for 5 h was first filtered with suction, then washed twice in 800 mL of distilled water, and finally dried in vacuum at 120° C. for 8 h to obtain a dry precursor. The obtained precursor was fully ground and mixed with a certain molar ratio of LiOH, and then heated in a muffle furnace at 5 °C min -1 The heating rate was first pre-calcined at 500°C for 5h, and then calcined at 600°C for 10h to obtain a lithium-rich nickel-b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com