Three-phase dual-active-bridge direct-current converter control system and control method

A technology of DC converter and dual active bridge, which is applied in the direction of control/regulation system, conversion of DC power input to DC power output, instruments, etc. It can solve the problems of slow response and achieve output voltage deviation, clear physical meaning, Effects that are easy to analyze

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

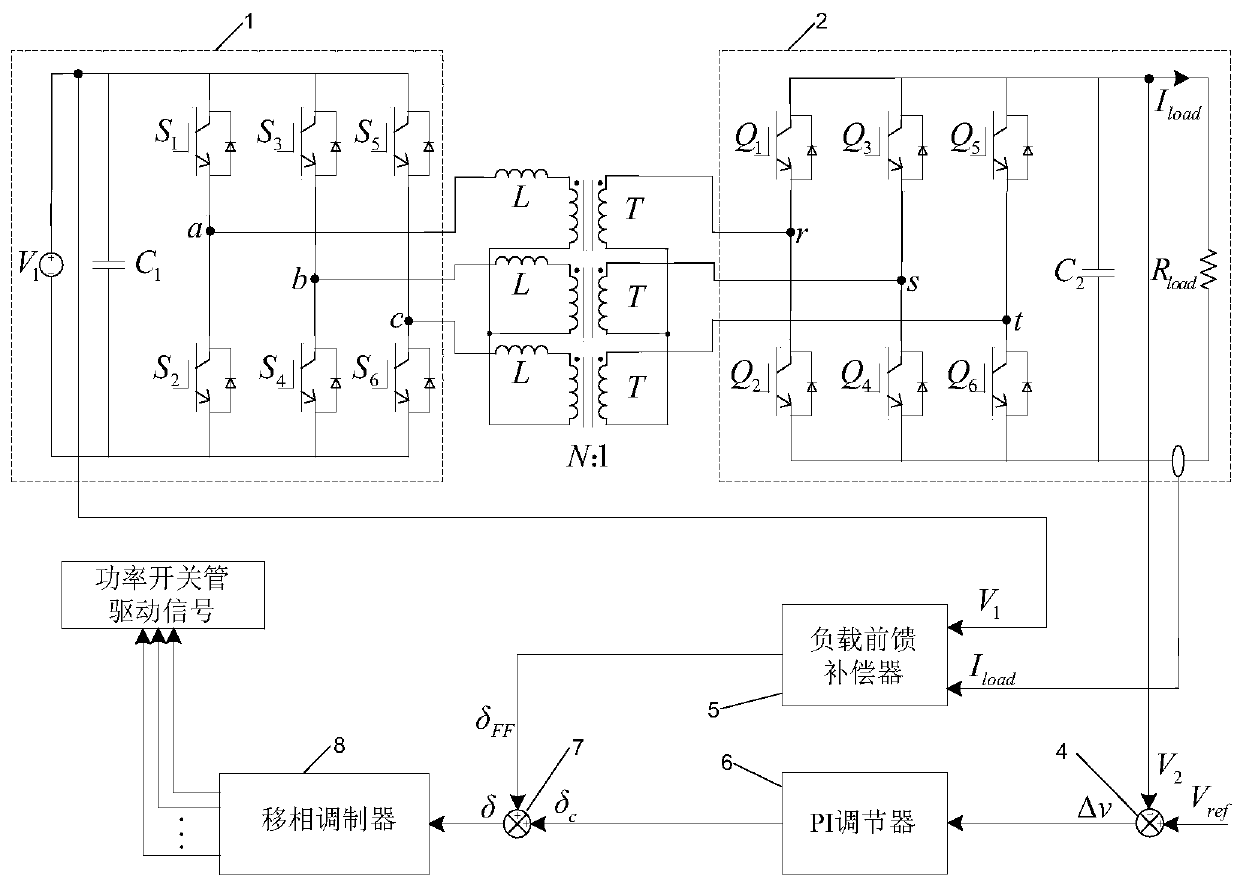

[0053] like figure 1 As shown, a three-phase dual active bridge DC converter control system includes a front-stage three-phase H-bridge inverter 1, a rear-stage three-phase H-bridge rectifier 2, three single-phase high-frequency transformers T, three A phase-shifting inductor L, the windings of the three single-phase high-frequency transformers T are connected to the front-stage three-phase H-bridge inverter 1 and the rear-stage three-phase H-bridge rectifier 2 according to a Y-Y-shaped connection mode, so that The three phase-shifting inductors L described above are respectively connected in series between the pre-stage three-phase H-bridge inverter 1 and the single-phase high-frequency transformer T; the three-phase dual active bridge DC converter control system also includes a power switch Tube drive system and load feed-forward compensation system.

[0054] The power switch tube drive system includes a first subtractor 4, a PI regulator 6, a first adder 7, a phase shift m...

Embodiment 2

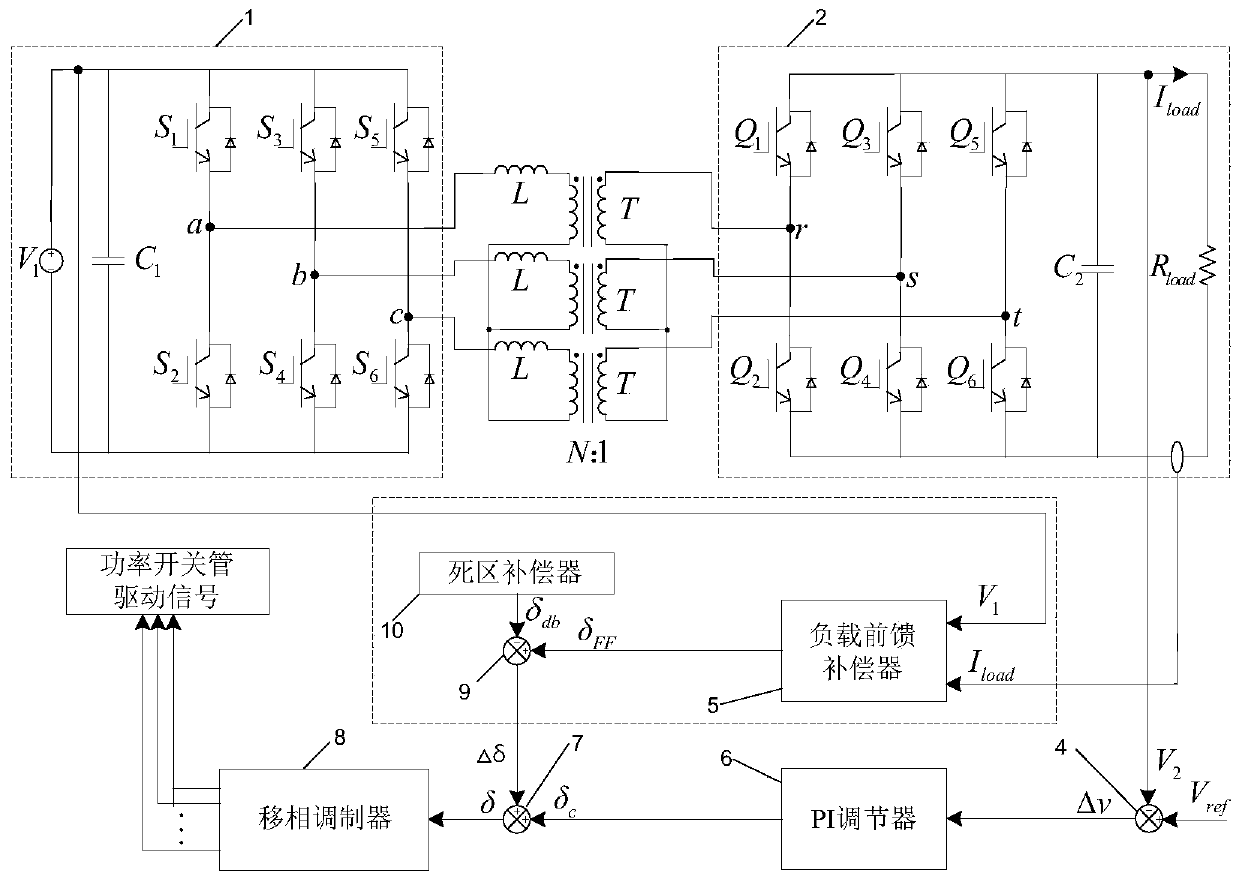

[0070] like figure 2 As shown, the difference between the three-phase dual active bridge DC converter control system of this embodiment and the first embodiment is that the load feed-forward compensation system also includes a second subtractor 9 and a dead zone compensator 10; The dead zone compensator 10 generates a phase shift angle command value δ for dead zone compensation db ; The second subtractor 9 will feed-forward compensation phase shift angle command value δ FF Phase shift angle command value δ with dead zone compensation db make difference to get δ FF -δ db , put δ FF -δ db Send into the first adder 7 and need to adjust the phase shift angle δ c Add to get the effective phase shift angle δ, that is, δ=δ c +δ FF -δ db .

[0071] The dead zone compensator 10 generates a phase shift angle command value δ for dead zone compensation db , is the command value of phase shift angle δ db The formula for calculating:

[0072]

[0073] Among them, δ s is th...

Embodiment 3

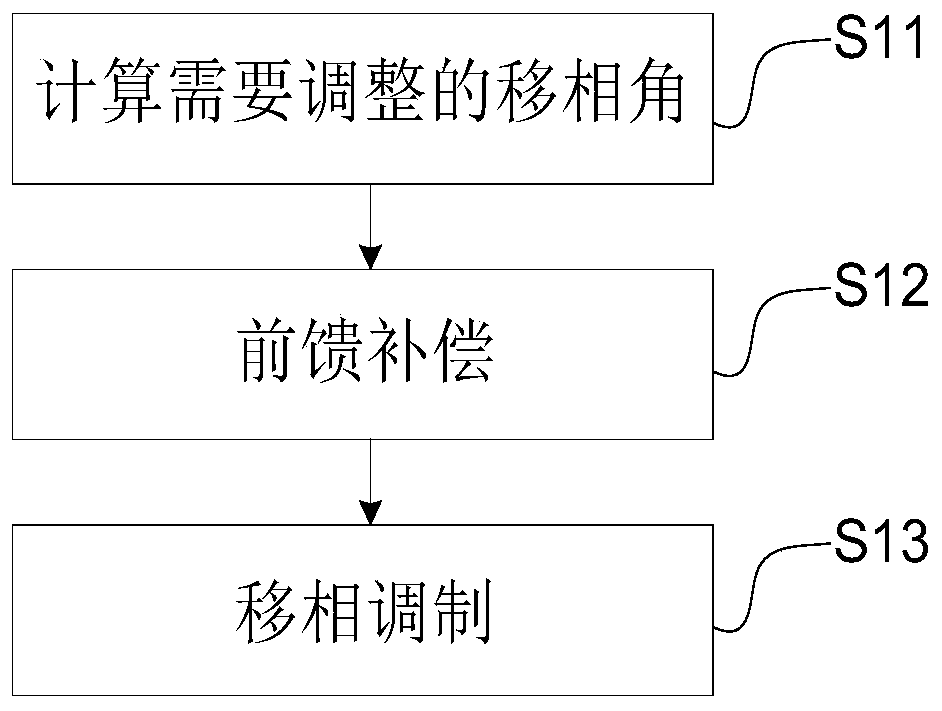

[0075] like image 3 As shown, a three-phase dual active bridge DC converter control method in this embodiment is applied to the control system described in Embodiment 1, and the control method includes the following steps: S11: Calculate the phase shift angle that needs to be adjusted ; S12: feedforward compensation, S13: phase shift modulation.

[0076] The control method of a three-phase dual active bridge DC converter in this embodiment has a clear physical meaning, is easy to analyze, and can well realize rapid stability and precise adjustment of the output voltage.

[0077] S11: Calculate the phase shift angle that needs to be adjusted, specifically:

[0078] The first subtractor 4 collects the system output DC voltage V 2 with a given output voltage reference V ref Make a difference to get the output voltage error signal Δv, and input the output voltage error signal Δv to the PI regulator to get the phase shift angle δ that needs to be adjusted c .

[0079] S12: Fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com