Method for preparing integral metal-based environmental catalyst by metal replacement method

A metal replacement and metal-based technology, which is applied in the field of preparation of organic waste gas overall metal-based oxidation catalysts, can solve the problems of cumbersome preparation methods, poor adhesion of active components, affecting catalytic activity and stability, and achieve high catalytic oxidation of VOCs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

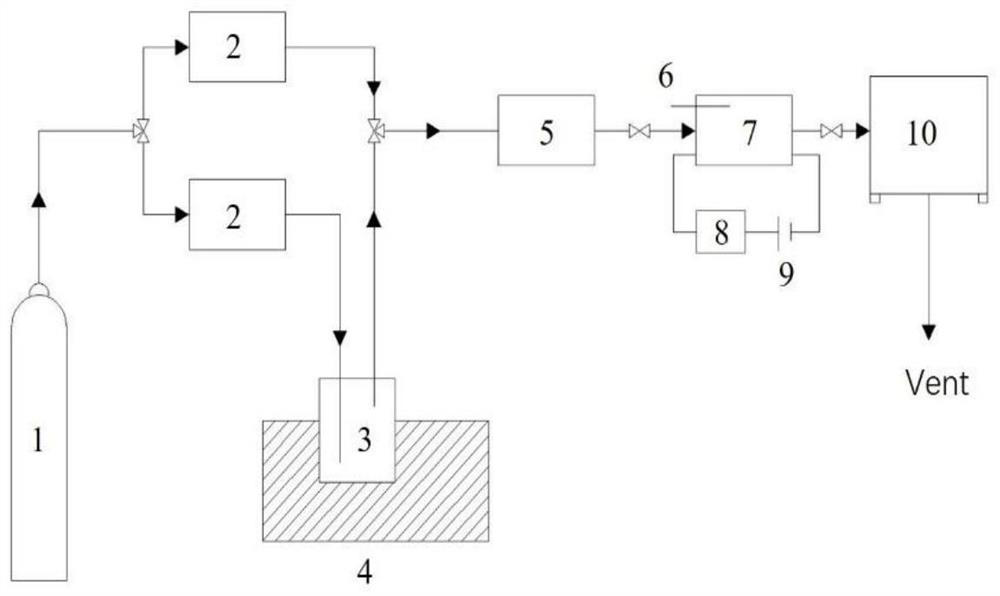

[0031] The preparation method of noble metal monolith catalyst of the present invention comprises the steps:

[0032] (1) Preparation of chloroplatinic acid and chloropalladium acid solution: take by weighing H 2 PtCl 6 ·6H 2 O or H 2 PdCl 4 Dissolve it in 250ml of water, configure it into a mother liquor of 2.5-12.5g / L (based on the quality of precious metal platinum or palladium), and prepare different concentrations of chloroplatinic acid or chloropalladium acid solutions with the mother liquor of 2.5-12.5g / L, called Take 50-200 mg of F127 and dissolve it therein as a noble metal precursor solution.

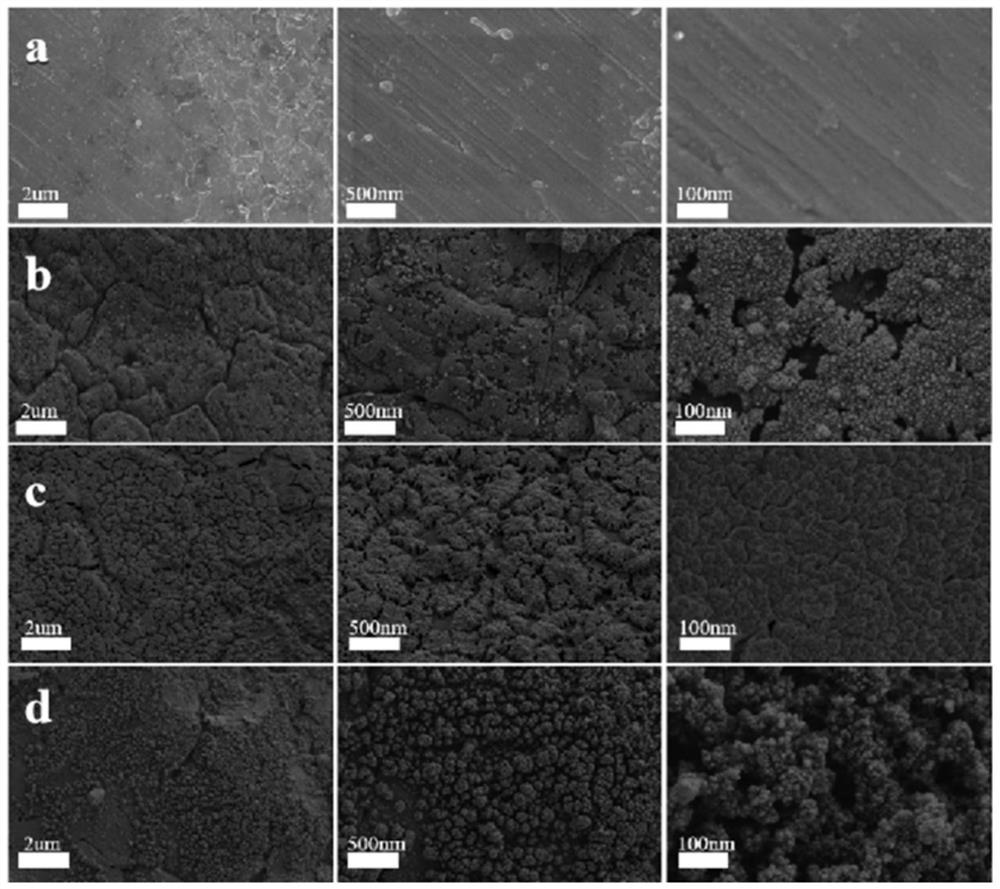

[0033] (2) Pretreatment of the metal carrier substrate: first place the metal material in acetone and ultrasonically vibrate for 30 minutes to remove surface oil stains. %-30%HNO 3 Ultrasonic vibration in the solution for 30 minutes to remove the oxide layer on the surface of the metal mesh, after the end, take it out and rinse it with deionized water, and treat it at 20...

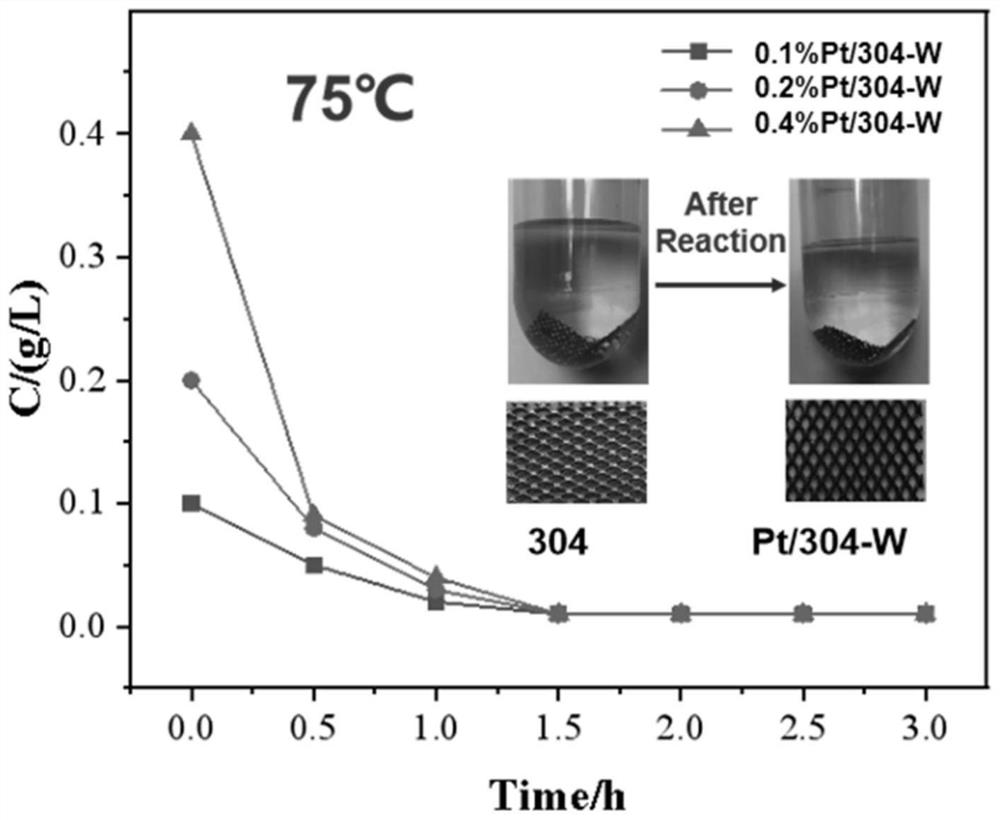

Embodiment 1

[0037] A monolithic catalyst with a loading of 0.1% Pt / 304 stainless steel was prepared. Take 0.4ml of 2.5g / L (based on the mass of platinum) mother liquor and mix it with 9.6ml of water, then add 50mg of F127 to make a 10ml solution in a test tube, put 1g of pretreated 304 stainless steel metal mesh into the test tube In 90 ℃ water bath, immersion replacement, every 10min with a UV spectrophotometer to measure the concentration of the solution until the Pt ion concentration becomes 0, then filter, 300 ℃ roasting 3h, the obtained catalyst is marked as: 0.1%Pt / 304-W.

Embodiment 2

[0039] A monolithic catalyst with a loading of 0.2% Pt / 304 stainless steel was prepared. The conditions are the same as in Example 1. Mix 0.8ml of 2.5g / L (based on the mass of platinum) mother liquor and 9.2ml of water, then add 50mg of F127 to form a 10ml solution in a test tube, and put 1g of pretreated 304 Put the stainless steel metal mesh into the test tube, immerse and replace it in a water bath at 90°C, measure the concentration change of the solution with a UV spectrophotometer every 10 minutes, until the Pt ion concentration becomes 0, then filter, roast at 300°C for 3 hours, and the obtained catalyst is labeled For: 0.2% Pt / 304-W.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com