Serial connection type soilless simple rice seedling growing tray for machine-transplanting hydroponically grown rice seedlings and rice seedling growing device

A seedling tray and series technology, which is applied in the field of machine-transplanted water-rolled seedling series-type soilless simple seedling trays and seedling devices, can solve the problems of frequent seedling replacement, high labor intensity and low efficiency of mechanical transplanting and transporting seedlings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

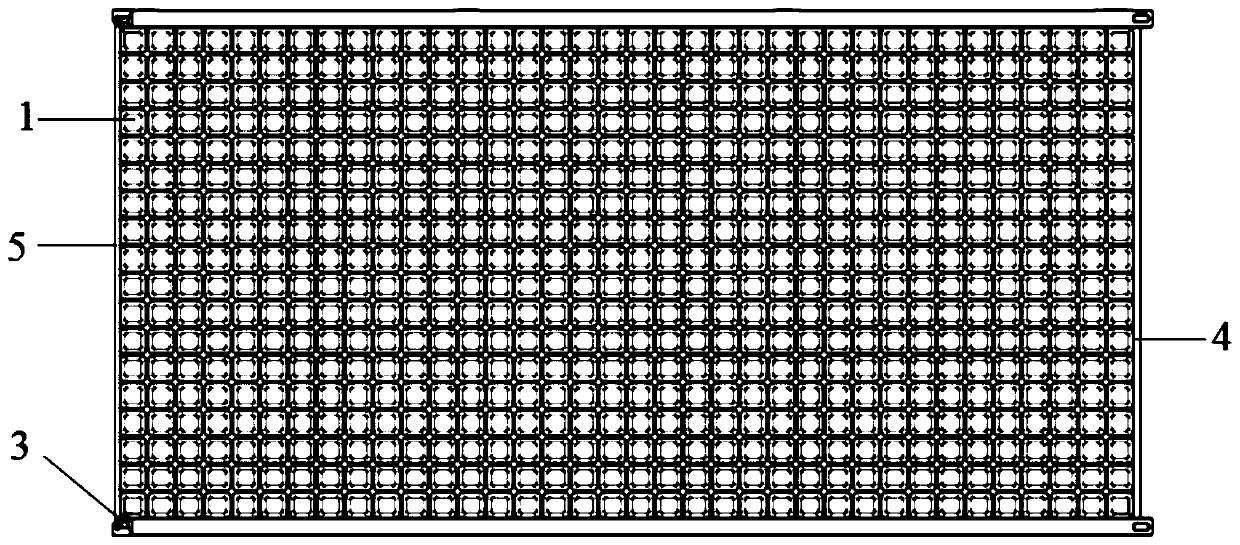

[0033] Such as Figure 1-Figure 6As shown, a simple soilless seedling tray of a machine-inserted water rolling seedling tandem type includes a U-shaped seedling-raising groove, and a plurality of water storage holes 1 are evenly arranged at the bottom of the seedling-raising groove. The two ends are respectively provided with wedge-shaped connectors 2 and wedge-shaped connectors 3 matched with the wedge-shaped connectors 2. Along the length direction of the seedling trough, the wedge-shaped connectors 2 protrude out of the outermost water storage hole, and two adjacent seedling trays pass through. The wedge-shaped connector 2 / wedge-shaped connector 3 and the wedge-shaped connector 3 / wedge-shaped connector 2 realize the serial connection of two seedling-raising trays; along the length direction of the seedling-raising trough, a "┌"-shaped The first baffle plate 4, the end of the wedge-shaped connection port 3 is provided with a vertical second baffle plate 5, the upper edge of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Upper width | aaaaa | aaaaa |

| Bottom width | aaaaa | aaaaa |

| Hole depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com