A machine-inserted water-rolled seedling series-type soilless simple seedling-raising tray and seedling-raising device

A seedling raising tray and series technology are applied in the field of soilless simple seedling raising trays and seedling raising devices in series for machine-transplanting water-rolled seedlings, which can solve the problems of frequent seedling changing, high labor intensity and low efficiency in mechanically transplanting seedlings and transporting seedlings. Improve the efficiency of transplanting, reduce the cost of raising seedlings, and make the production simple and convenient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

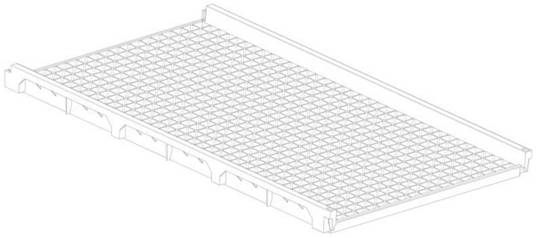

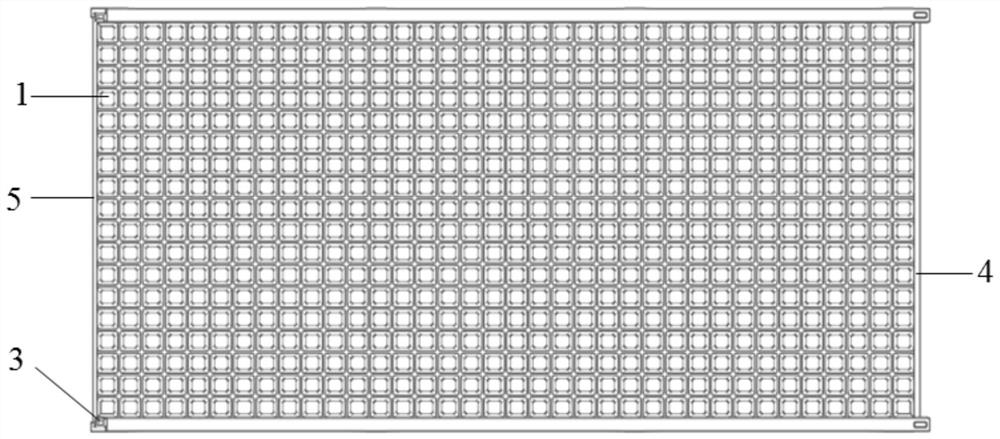

[0033] like Figure 1-Figure 6As shown, a simple soilless seedling tray of a machine-inserted water rolling seedling tandem type includes a U-shaped seedling-raising groove, and a plurality of water storage holes 1 are evenly arranged at the bottom of the seedling-raising groove. The two ends are respectively provided with wedge-shaped connectors 2 and wedge-shaped connectors 3 matched with the wedge-shaped connectors 2. Along the length direction of the seedling trough, the wedge-shaped connectors 2 protrude out of the outermost water storage hole, and two adjacent seedling trays pass through. The wedge-shaped connector 2 / wedge-shaped connector 3 and the wedge-shaped connector 3 / wedge-shaped connector 2 realize the serial connection of two seedling-raising trays; along the length direction of the seedling-raising trough, a "┌"-shaped The first baffle plate 4, the end of the wedge-shaped connection port 3 is provided with a vertical second baffle plate 5, the upper edge of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com