Protective mask preparation method

A technology for preparing masks and raw materials, applied in protective clothing, tools for sewing clothes, clothing, etc., can solve the problems of increasing the use of raw materials, inconvenient sales, increasing antibacterial fabrics, etc., so as to improve air circulation and increase wearing comfort. degree, the effect of increasing the antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

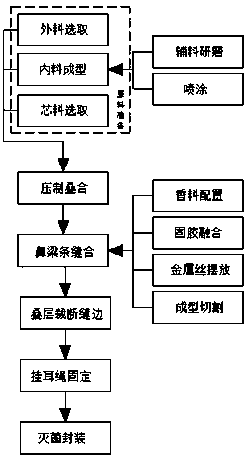

Image

Examples

preparation example Construction

[0029] The invention provides a technical scheme: a method for preparing a protective mask, comprising the following steps:

[0030] S1: Raw material preparation:

[0031] Selection of outer materials: select conventional spunbonded non-woven fabrics in the market;

[0032] Inner material molding: 1) Grinding of auxiliary materials, 2) Spraying;

[0033] Grinding temperature is 34°C-36°C; dry and ferment, stir the auxiliary materials every 10 minutes, each time 1-2 minutes, and inject twice the weight of the auxiliary materials with water to continue stirring, let stand for 20-30 minutes, and take the supernatant;

[0034] Spray the supernatant on both sides of the melt-blown cloth with a spraying device and an ultra-fine nozzle, and then dry it at a temperature of 25°C to 30°C and a drying time of 2 minutes to 5 minutes;

[0035] Core material selection: select conventional moisture-resistant and anti-stick non-woven fabrics in the market;

[0036] Spunbonded non-woven fab...

Embodiment

[0048] A method for preparing a protective mask, comprising the steps of:

[0049] S1: Raw material preparation:

[0050] Selection of outer materials: select conventional spunbonded non-woven fabrics in the market;

[0051] Inner material molding: 1) Grinding of auxiliary materials, 2) Spraying;

[0052] Grinding temperature is 34°C; dry and ferment, stir the auxiliary materials every 10 minutes, each time is 2 minutes, and pour twice the weight of auxiliary materials into the water to continue stirring, let stand for 30 minutes, and take the supernatant;

[0053] Spray the supernatant on both sides of the melt-blown cloth with a spraying device and an ultra-fine nozzle, and then dry it at a temperature of 25°C and a drying time of 4 minutes;

[0054] Core material selection: select conventional moisture-resistant and anti-stick non-woven fabrics in the market;

[0055] Spunbonded non-woven fabrics, melt-blown fabrics, and moisture-resistant and anti-stick non-woven fabric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com