Carbon dioxide marking machine

A carbon dioxide, marking machine technology, applied in the field of marking machines, can solve the problems of inconvenient operation, inability to conveniently record the number of marked objects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

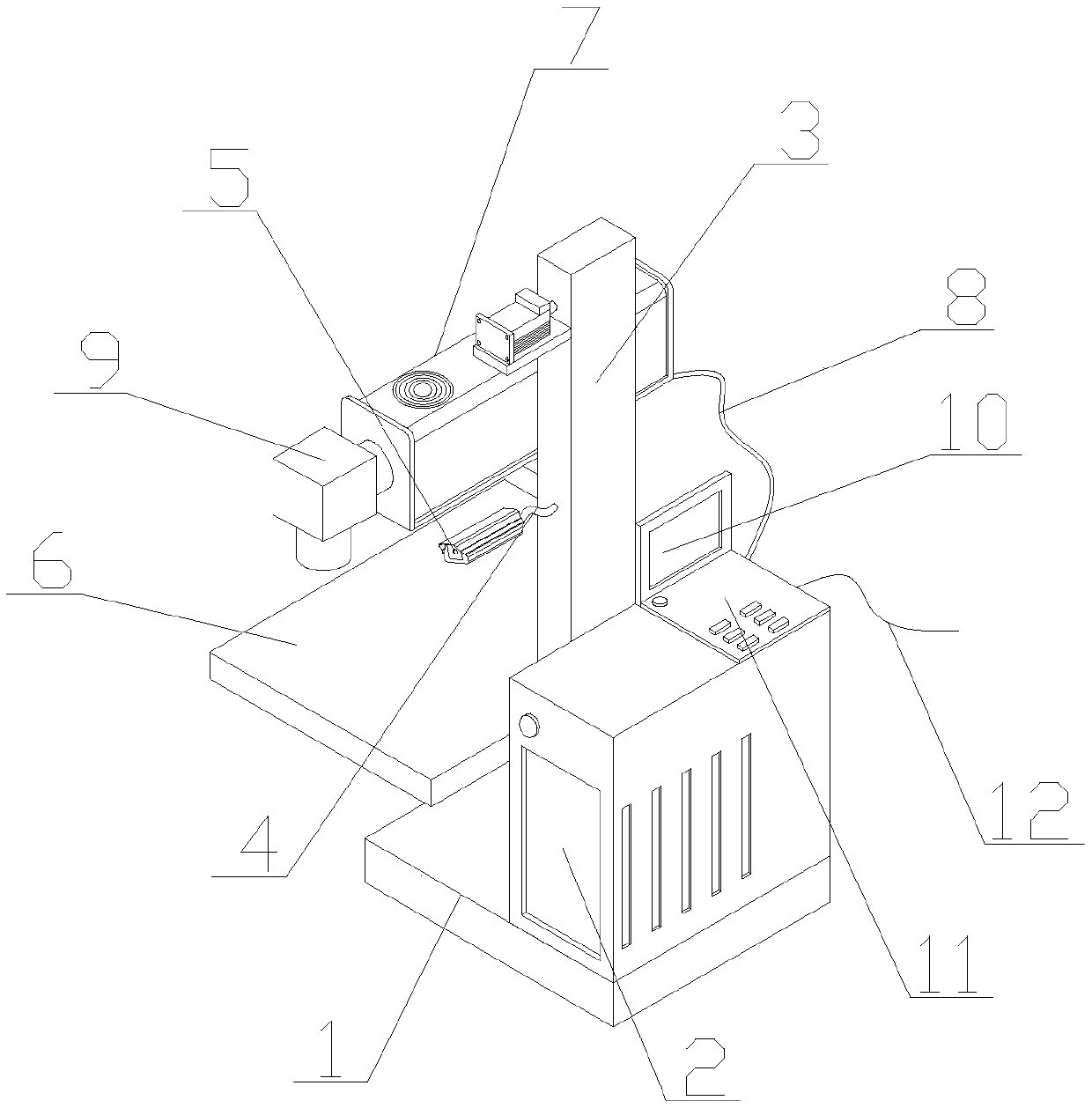

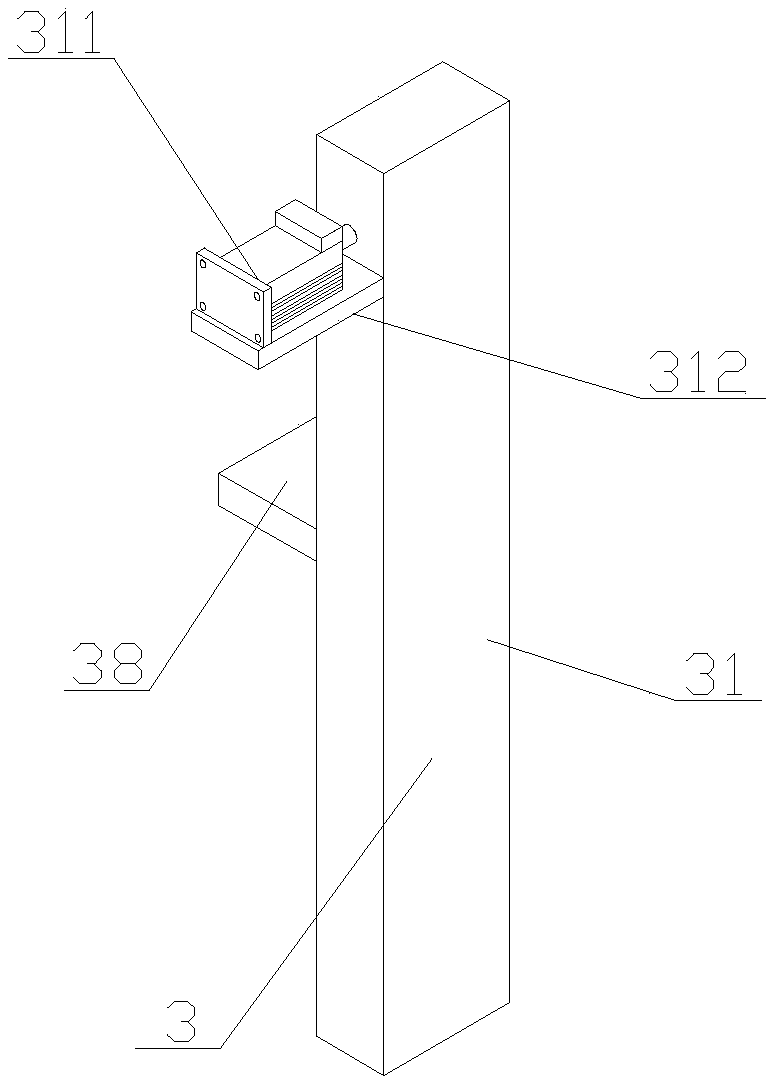

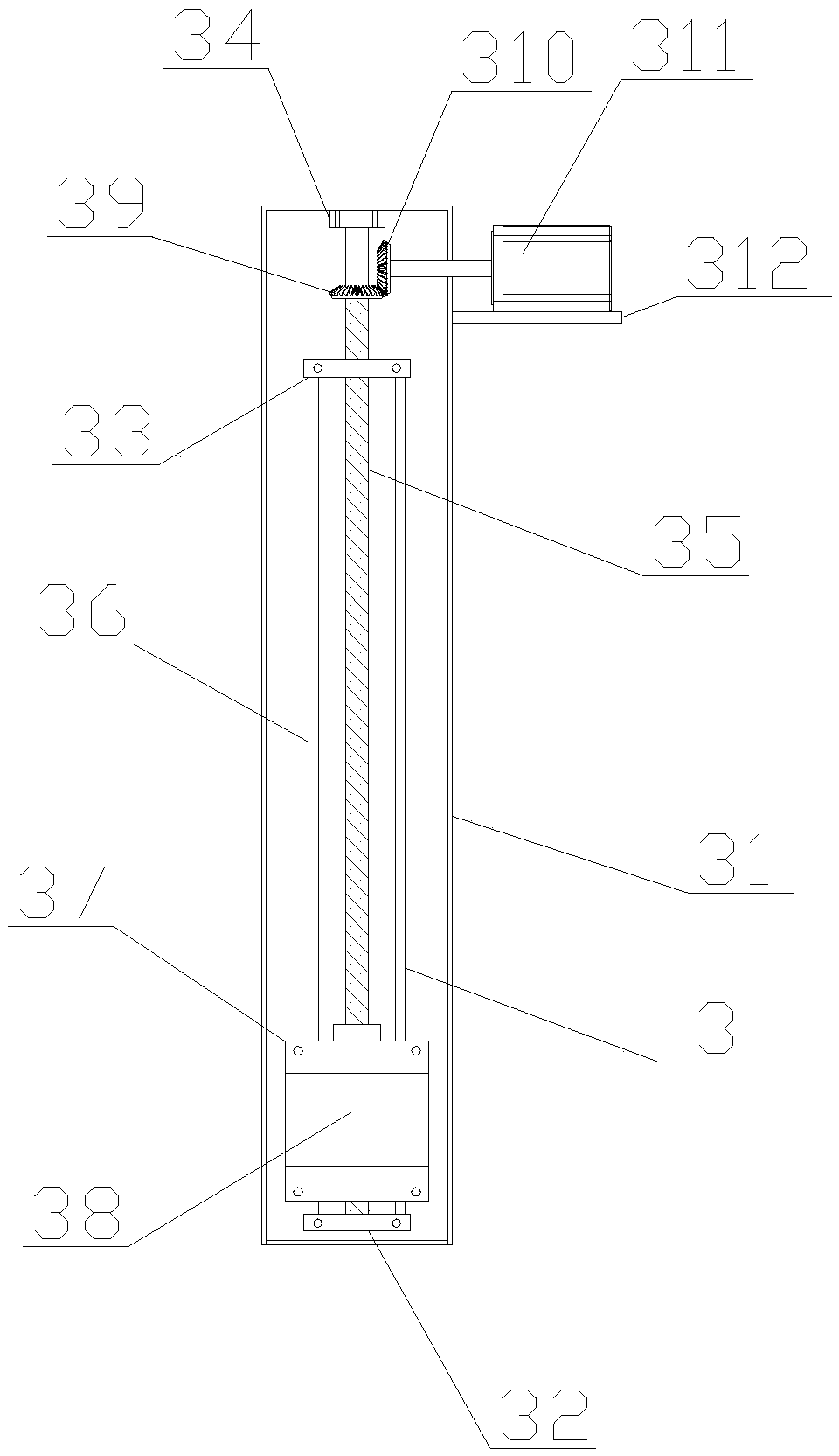

[0028] In this technical solution:

[0029] Lifting device 3, circuit board 13, housing 31, first fixed block 32, second fixed block 33, bearing 34, threaded rod 35, fixed rod 36, sliding plate 37, first support plate 38, first bevel gear 39, Second bevel gear 310, drive motor 311, second support plate 312, circuit board main body 131, microprocessor 132, storage module 133, first port 134, second port 135, third port 136, fourth port 137, The fifth port 138, the sixth port 139 and the seventh port 1310 are substantially innovative components of the present invention.

[0030] Base 1, cabinet 2, soft support bar 4, enlarged camera 5, placement plate 6, high-voltage discharge tube 7, air intake pipe 8, marking head 9, display screen 10, controller 11 and power cord 12 are for realizing the technology of the present invention An essential connectivity building block of a scheme.

[0031] In order to make the object, technical solution and advantages of the present invention cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com