Chemical mechanical polishing solution

A chemical mechanical and polishing liquid technology, applied in the direction of polishing compositions containing abrasives, etc., can solve problems such as increased stability, easy aggregation of abrasive particles and by-products, scratches on polishing pads, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The advantages of the present invention are further described below through specific examples, but the protection scope of the present invention is not limited only to the following examples.

[0028] The silica abrasive particles used in the present invention can be purchased on the market, or can be obtained by reacting a silane coupling agent with a sulfonic acid group at the end and silica particles.

[0029] The azole compound used in the present invention is weakly acidic in itself, and has a strong pH buffering capacity in an alkaline environment, so that it can be added to an alkaline polishing solution to form a buffer solution, so that the polishing solution can be recycled in the process of using Has a stable polishing rate.

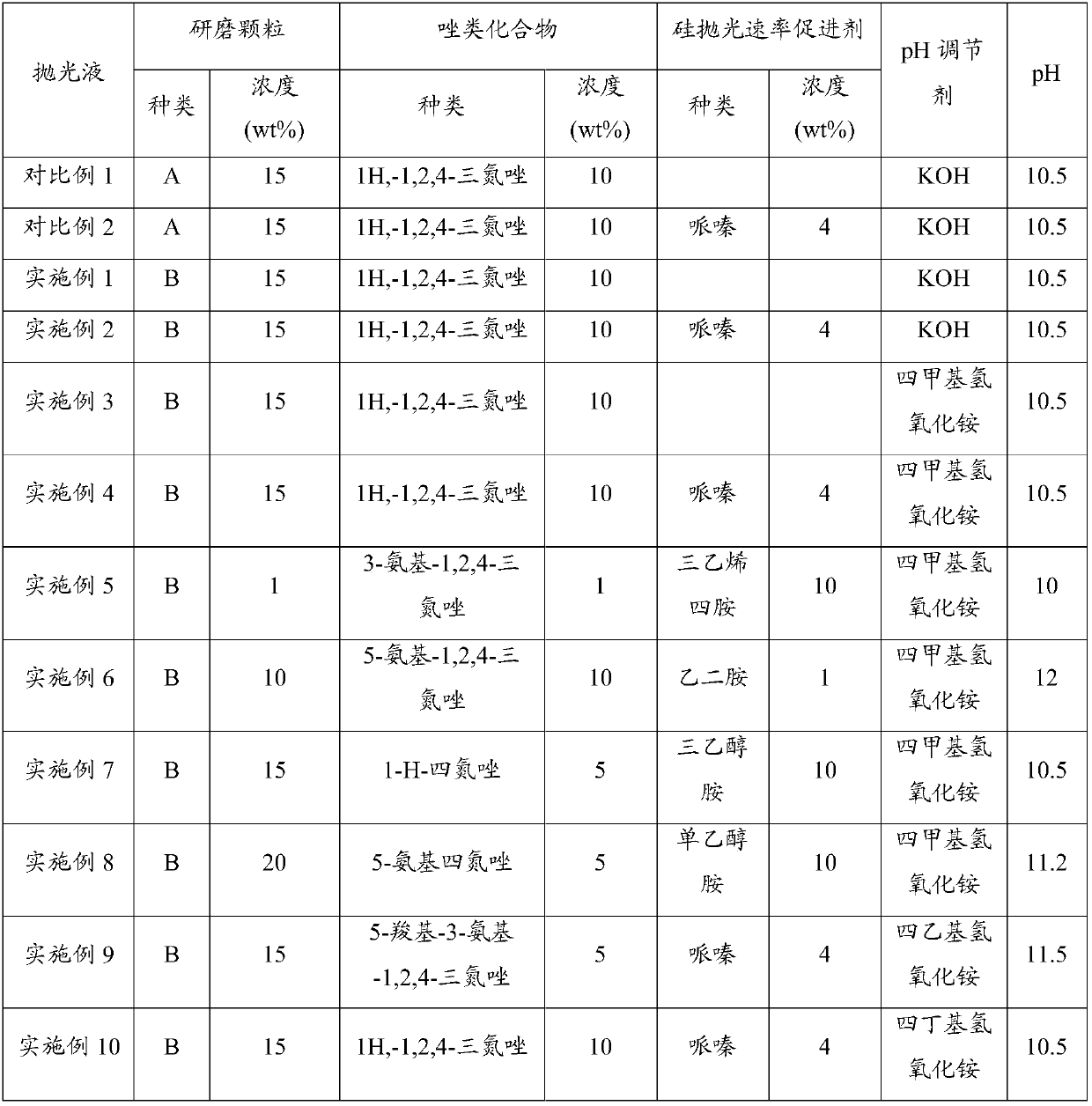

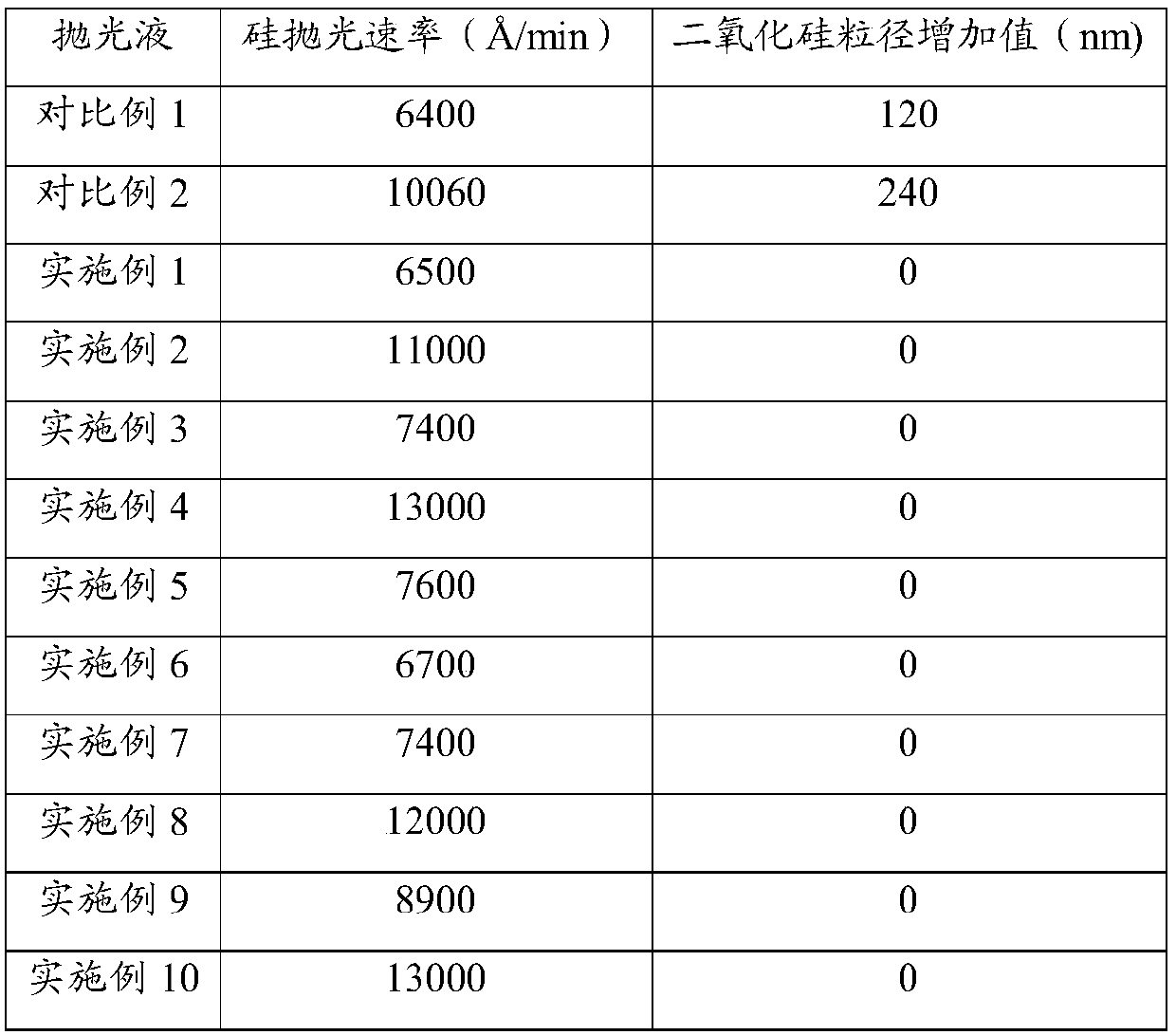

[0030] Table 1 shows the composition formulations of the chemical mechanical polishing fluids of Examples 1-10 and Comparative Examples 1-2 of the present invention. Wherein, the contents are expressed in mass percent (wt%). Abrasive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com