High-colour-fastness composite fiber capable of preventing dye from sensitizing and causing cancer, and preparation method for high-colour-fastness composite fiber

A composite fiber and high color fastness technology, applied in the direction of fiber chemical characteristics, adding dyes in spinning solution, rayon manufacturing, etc., can solve the problems of fabric color difference, difficult to spin fine denier yarn, poor coloring power, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] Specifically, the present invention also provides a preparation method of a composite fiber with high color fastness and anti-sensitization and carcinogenicity of dyes, comprising the following steps:

[0036] Step 1: Preparation of cortex material, uniformly mix PE and PE masterbatch, heat and melt with the first single screw to obtain the melted cortex material, the melted cortex material is filtered by the first filter and metered by the first metering pump, and then sent to compounding Fiber spinning box;

[0037] Specifically, the first single screw in step 1 includes 5 temperature zones: 250°C, 270°C, 280°C, 280°C, and 275°C. The functions of each zone are superimposed and strengthened, and each has its own emphasis. The main function It is feeding, compressing, preheating, heating, homogenizing, etc., to ensure that the materials are evenly mixed and heated.

[0038] Step 2: Preparation of the core layer material. The polyester and the colorant are uniformly mix...

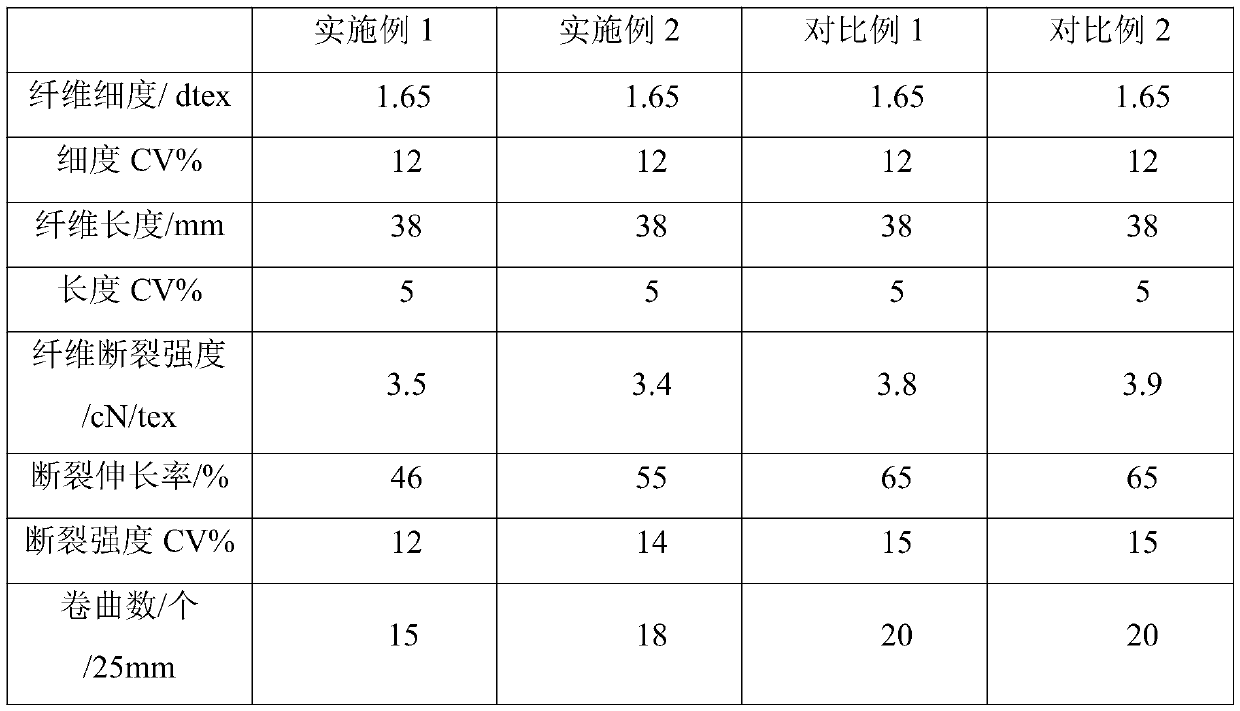

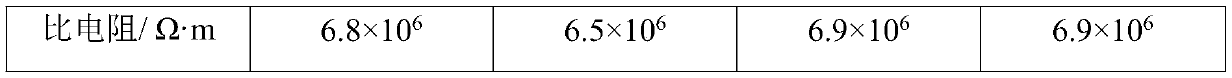

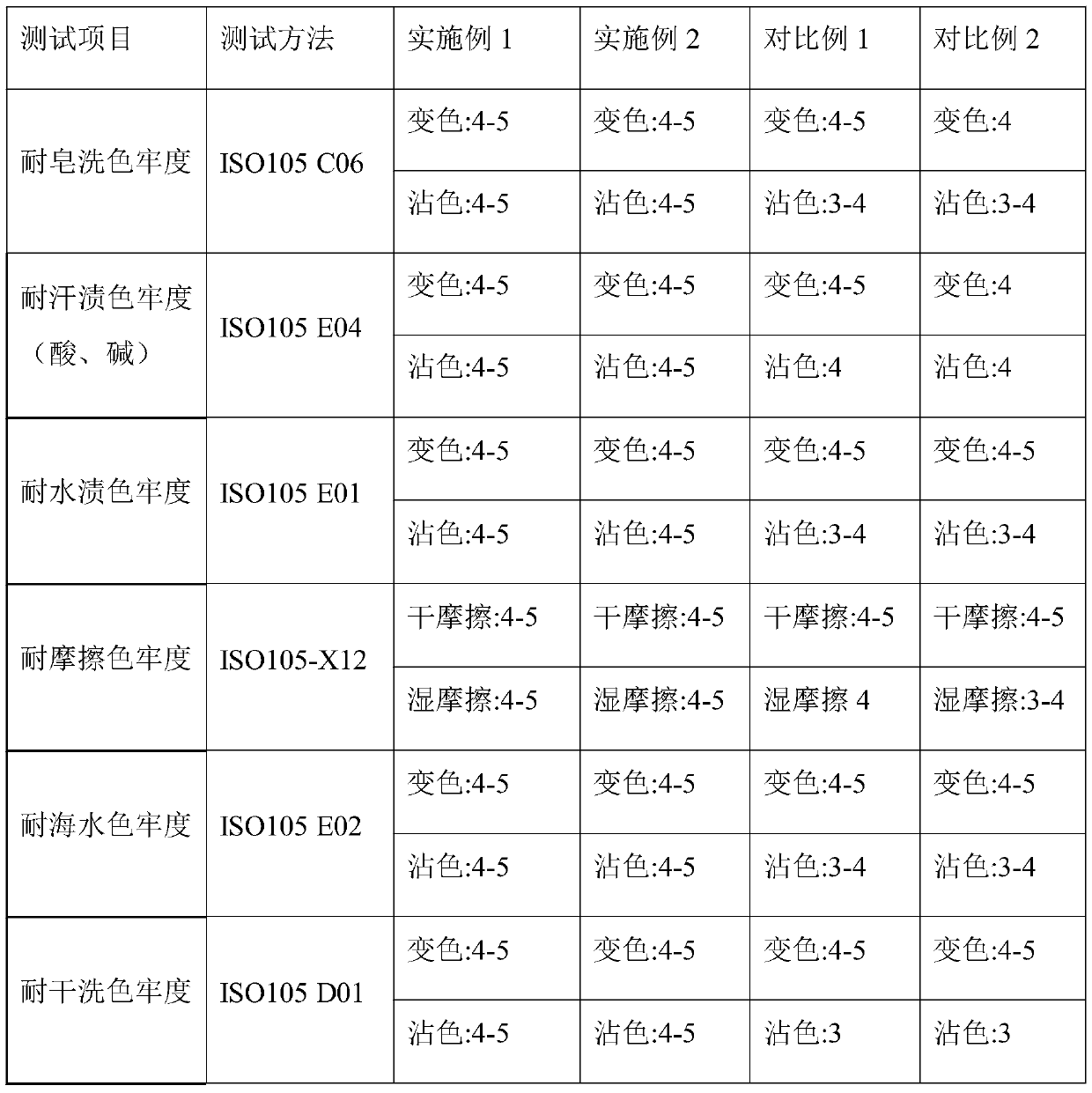

Embodiment 1

[0049] This example provides a composite fiber with high color fastness and anti-dye sensitization and carcinogenicity. The composite fiber includes a core layer and a skin layer wrapped on the outer surface of the core layer. The core layer is made of polyester and a colorant, and the skin layer is made of polyester. It is prepared from ethylene (PE) and polyethylene barrier masterbatch (PE masterbatch).

[0050] Among them, the mass ratio of the skin layer to the core layer is 50:50; the mass ratio of polyethylene and barrier masterbatch in the skin layer is 100:3; the mass ratio of polyester and colorant (solvent yellow 114) in the core layer is 100:1 .

[0051] The high color fastness anti-dye sensitization and carcinogenic composite fiber of this embodiment is prepared by the following method:

[0052] (1) Evenly mix commercially available polyethylene and barrier masterbatch (the mass ratio of polyethylene and barrier masterbatch is 100:2) as the skin layer material, he...

Embodiment 2

[0057] This example provides a composite fiber with high color fastness and anti-dye sensitization and carcinogenicity. The composite fiber includes a core layer and a skin layer wrapped on the outer surface of the core layer. The core layer is made of polyester and a colorant, and the skin layer is made of polyester. It is prepared from ethylene (PE) and polyethylene barrier masterbatch (PE masterbatch).

[0058] Among them, the mass ratio of the skin layer to the core layer is 50:50; the mass ratio of polyethylene and barrier masterbatch in the skin layer is 100:3; the mass ratio of polyester and colorant (solvent violet 13) in the core layer is 100:1 .

[0059] The high color fastness anti-dye sensitization and carcinogenic composite fiber of this embodiment is prepared by the following method:

[0060] (1) Evenly mix commercially available polyethylene and barrier masterbatch (the mass ratio of polyethylene and barrier masterbatch is 100:2) as the skin layer material, hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Moisture content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com