Light guide and condensation structure for surface-mounted LED

A technology of light-emitting diode and light-concentrating structure, applied in the field of light-concentrating structure and light guide, can solve the problems of difficulty in independent application of equipment, inability to concentrate, and large design area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

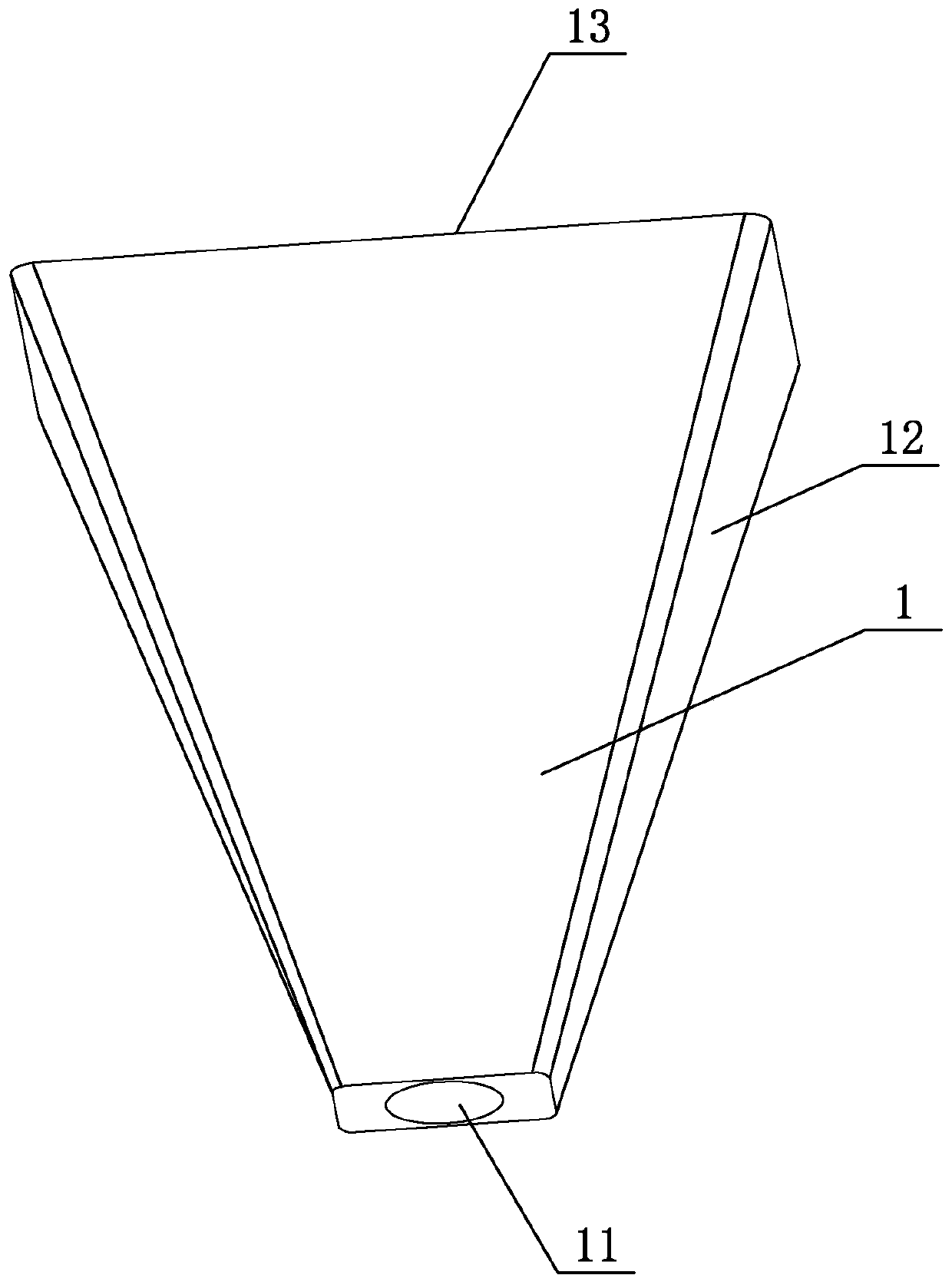

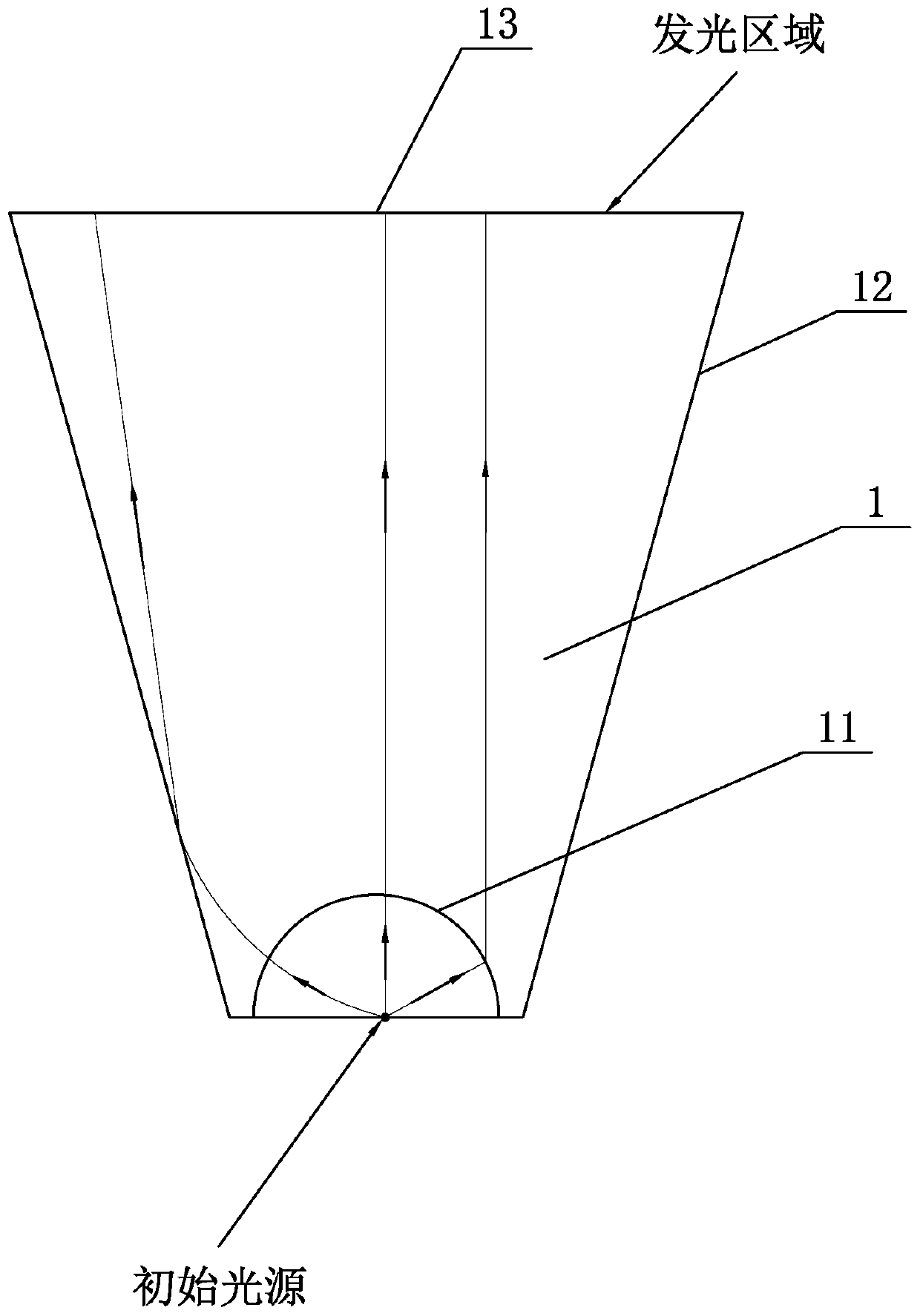

[0028] A light-guiding and light-condensing structure for patch LED light-emitting diodes, refer to figure 1 It can be seen that the shape of the main body is composed of the main body 1, the outer shape of the main body 1 is in the shape of a square truss, the interior of the main body 1 is a solid structure, and the main body 1 is made of transparent PC material by injection molding, forming a fully transparent structure. The outer surface around the body 1 is a total reflection surface 12 , and the bottom surface of the body 1 is a light-emitting surface 13 . Wherein, the total reflection surface 12 is a smooth surface, and its surface roughness is below 0.8.

[0029] The top surface of the quadrangular pedestal is provided with a concave scattering spherical surface 11, and the scattering spherical surface 11 is a concave hemispherical surface. The position of the center of the sphere 11.

[0030] When in use: the initial light source is made of 3258 SMD LED lamp beads, ...

Embodiment 2

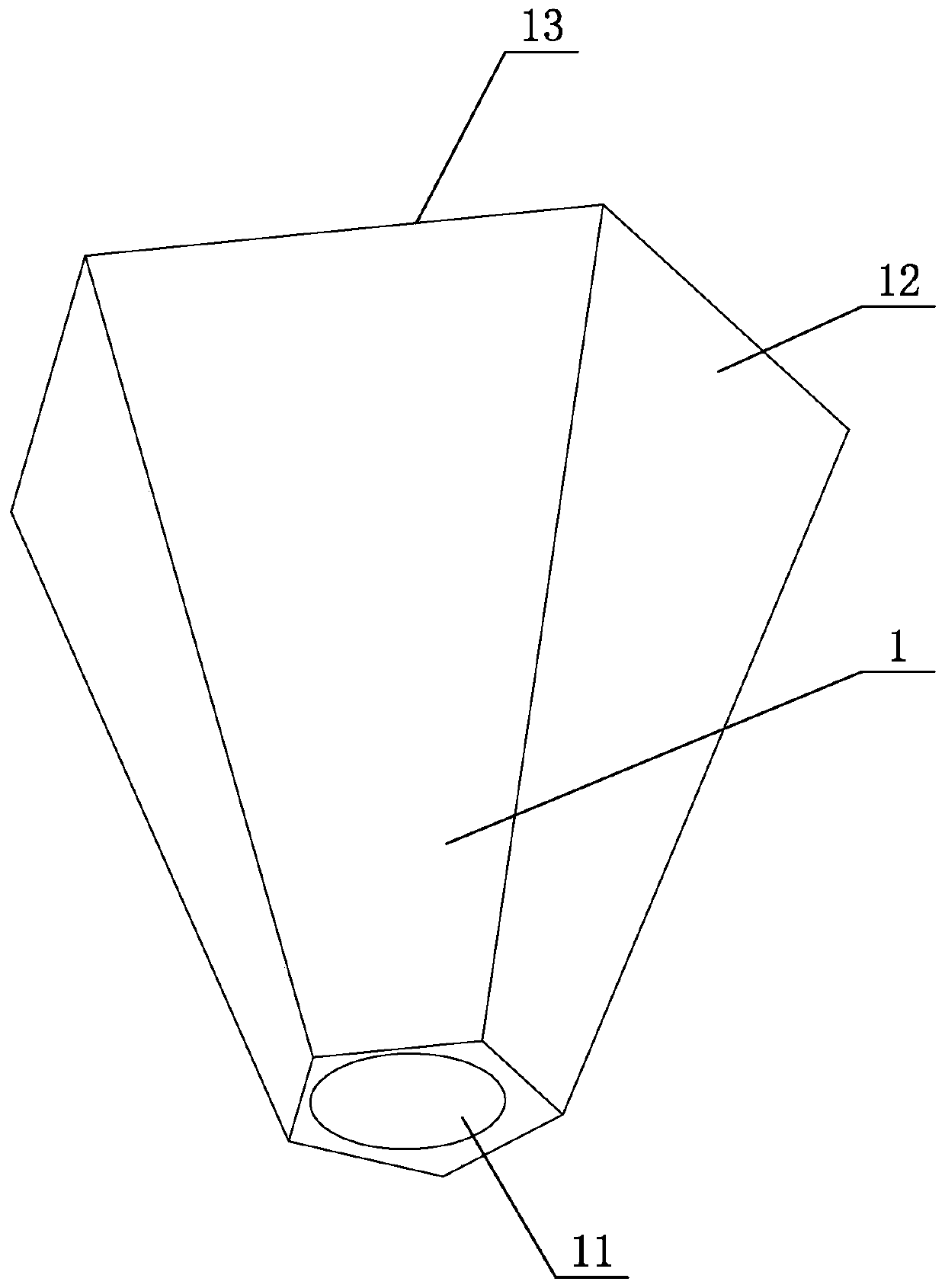

[0032] A light-guiding and light-condensing structure for patch LED light-emitting diodes, refer to figure 1 It can be seen that the shape of the main body is composed of the main body 1, the outer shape of the main body 1 is a pentagonal truss shape, the interior of the main body 1 is a solid structure, and the main body 1 is made of transparent PC material by injection molding, forming a fully transparent structure. The outer surface around the body 1 is a total reflection surface 12 , and the bottom surface of the body 1 is a light-emitting surface 13 . Wherein, the total reflection surface 12 is a smooth surface, and its surface roughness is below 0.8.

[0033] The top surface of the five-prism platform is provided with a concave scattering spherical surface 11, and the scattering spherical surface 11 is a concave hemispherical surface. The position of the center of the sphere 11.

[0034] When in use: the initial light source is made of 3258 SMD LED lamp beads, its lumi...

Embodiment 3

[0036] A light-guiding and light-condensing structure for patch LED light-emitting diodes, refer to figure 1 It can be seen that the shape of the main body is composed of the body 1, the shape of the body 1 is in the shape of a hexagonal truss, the interior of the body 1 is a solid structure, and the body 1 is made of transparent PC material by injection molding, forming a fully transparent structure. The outer surface around the body 1 is a total reflection surface 12 , and the bottom surface of the body 1 is a light-emitting surface 13 . Wherein, the total reflection surface 12 is a smooth surface, and its surface roughness is below 0.8.

[0037] The top surface of the hexagonal platform is provided with a concave scattering spherical surface 11, and the scattering spherical surface 11 is a concave hemispherical surface. The position of the center of the sphere 11.

[0038] When in use: the initial light source is made of 3258 SMD LED lamp beads, its luminous points are co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com