High-voltage high-capacity split reactance type current limiter

A technology of split reactor and split reactance, which is applied in the direction of transformer/inductor coil/winding/connection, transformer/inductor parts, circuits, etc., which can solve the problems of low port withstand voltage and large footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

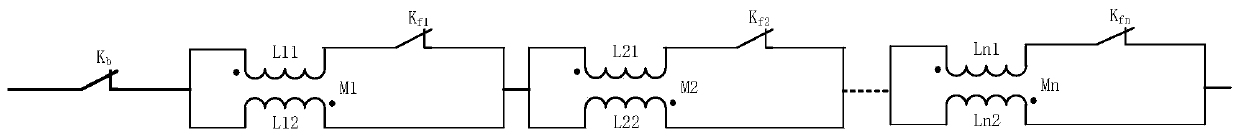

[0017] figure 1 Shown is the equivalent circuit diagram of a conventional multi-module split reactance current limiter. Such as figure 1 As shown, the multi-module split reactance current limiter is composed of multiple high-coupling split reactor modules and multiple fast circuit breaker modules.

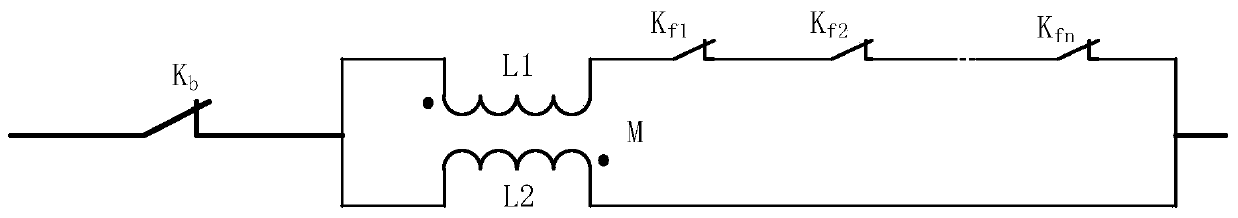

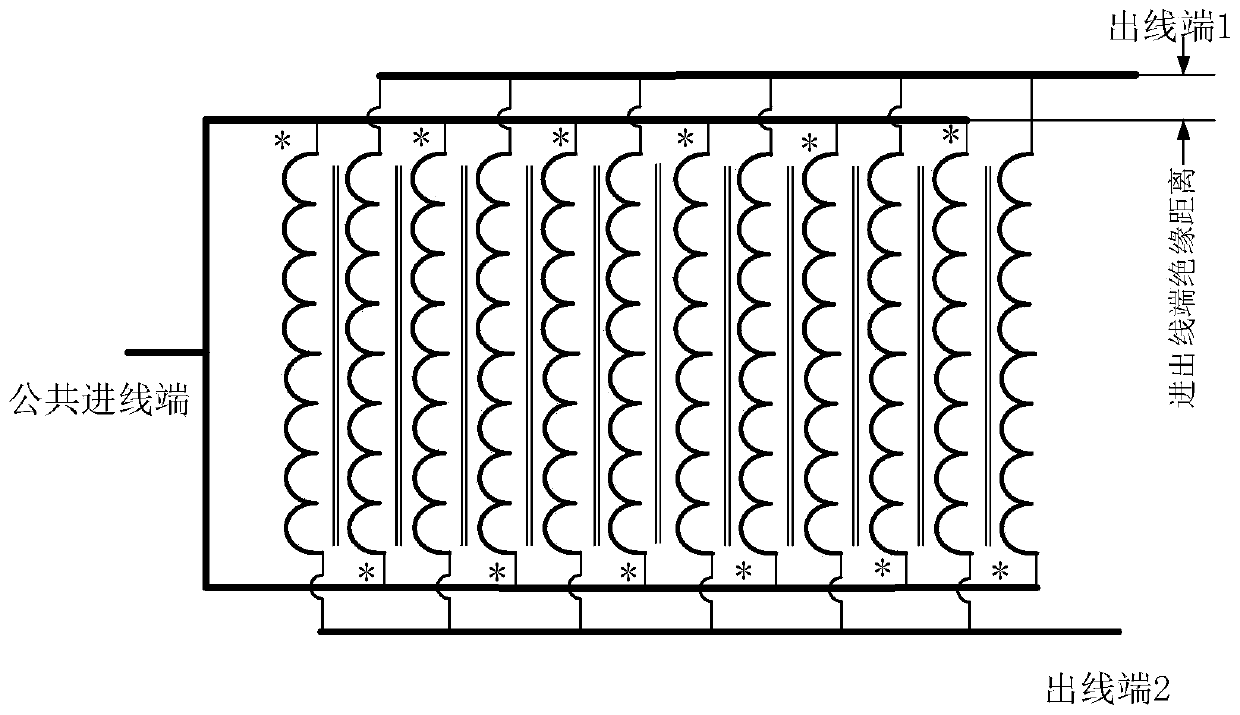

[0018] figure 2 Shown is the equivalent circuit diagram of the embodiment of the high-voltage and large-capacity split reactance current limiter of the present invention. Such as figure 2 As shown, the high-voltage split reactance current limiter is composed of a high-voltage split reactor and a multi-fracture fast circuit breaker. The high-voltage split reactor adopts a high-end withstand voltage coil structure and outlet mode; the operating mechanism of the multi-fracture fast circuit breaker adopts an electromagnetic repulsion mechanism, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com