Recycling device and method of waste fiber type heat preservation materials

A technology for thermal insulation materials and waste fibers, applied in chemical instruments and methods, solid separation, sieves, etc., can solve the problems of decreased thermal insulation performance, limited application scope, loss of fiber characteristics, etc., and achieves high recycling rate and large processing capacity. , The effect of solving the problem of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

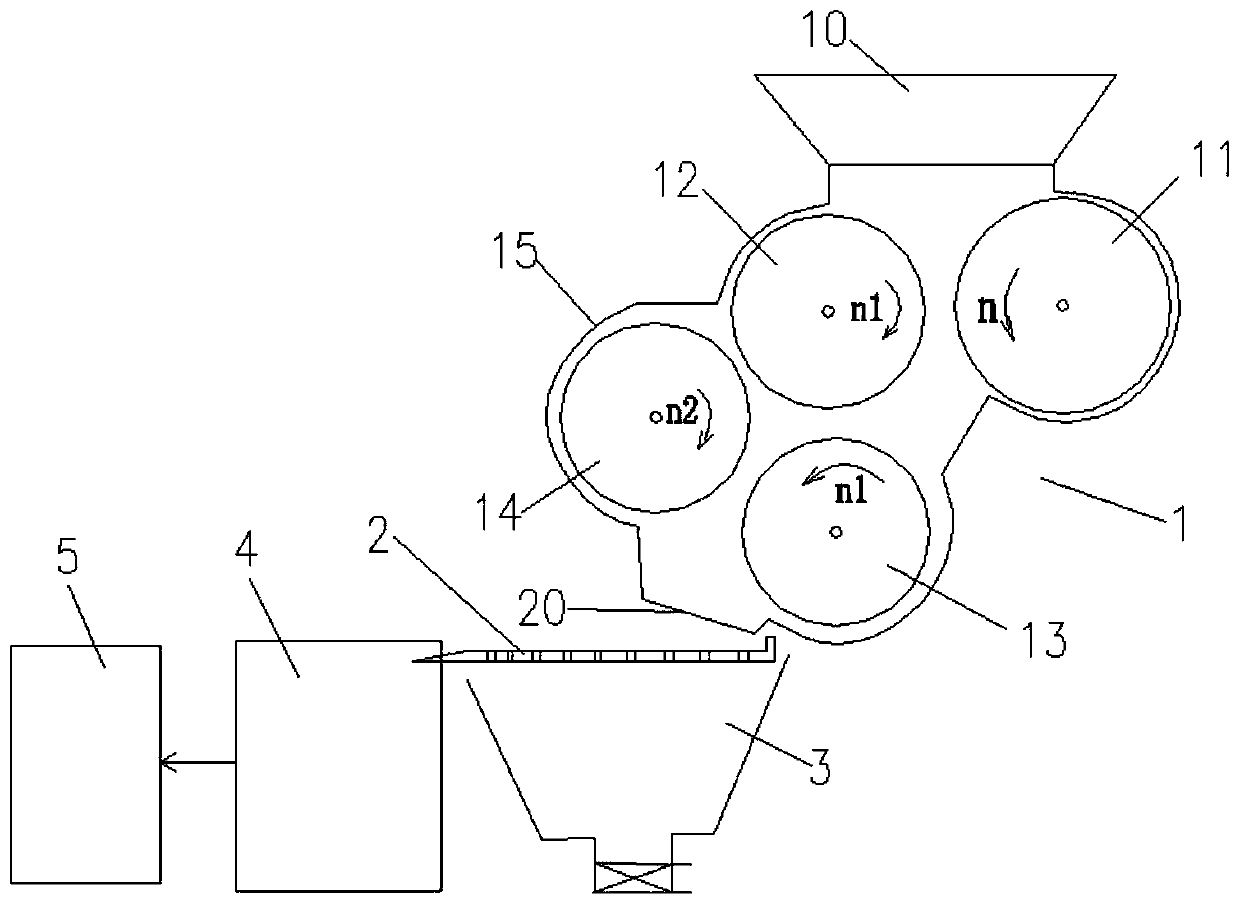

[0023] Such as figure 1 As shown, this embodiment provides a set of recycling device for waste fiber insulation materials, the set of equipment is generated by fiber decomposition equipment 1, vibrating screening equipment 2, shredded fiber bin 3 and rubberized fibers as usable fiber recovery treatment equipment Composed of equipment 4, the glued fiber production equipment 4 is connected with the production line 5 of the recycled thermal insulation material.

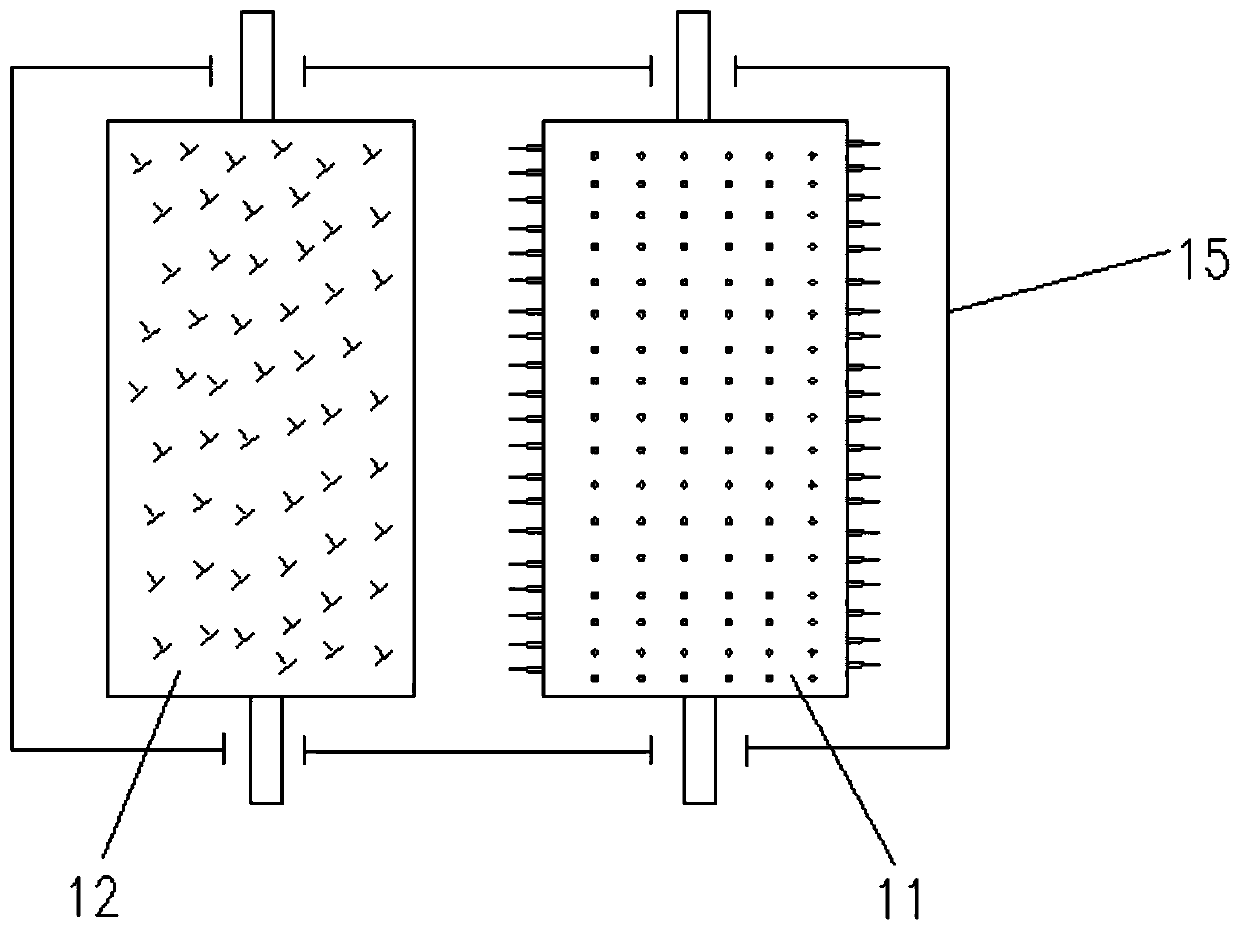

[0024] The structure of the fiber disintegration device 1, such as figure 1 Shown: it comprises a feed port 10 and a discharge port 20, the feed port 10 is positioned at the uppermost end of the fiber decomposition device 1, the discharge port 20 is positioned at the bottom end of the fiber decomposition device 1, the feed port 10 and the discharge port Between the ports 20 is a closed cavity. In the closed cavity 15, there are four rollers, wherein the first roller 11 and the fourth roller 14 are toothed rollers, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com