Method and device for constructing super hydrophobic bionic spider silk moisture collection device with 3D printing technology

A collection device and 3D printing technology, applied in the field of bionics, can solve problems such as difficulty in manufacturing controllable 3D geometric shapes, and achieve the effect of improving water collection efficiency and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

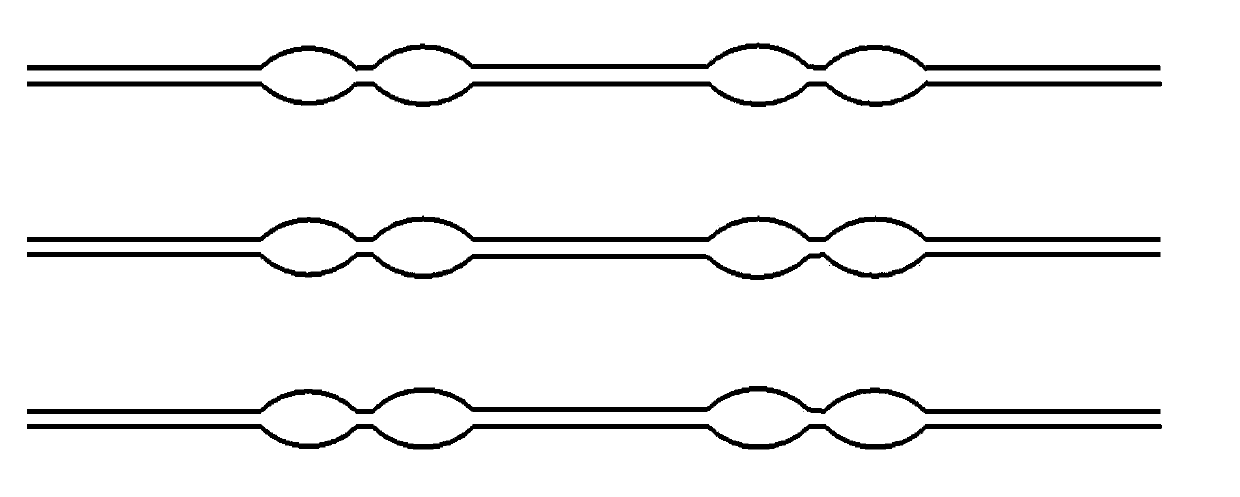

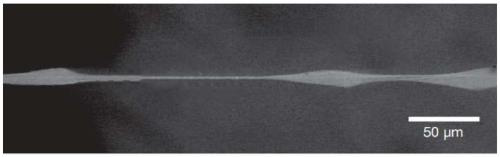

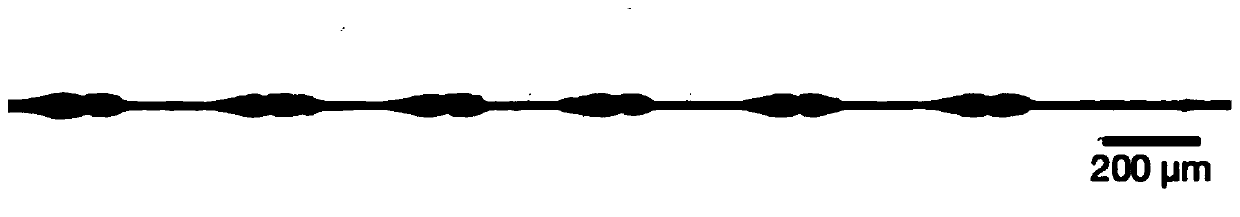

[0031] The composite photocurable resin was prepared by mixing the pretreated photocurable polymer alkali-free glass fiber (E-glass) and multi-walled carbon nanotubes (MWCNTs), and the periodic arrangement was printed by a photocurable 3D printer (DLP) The bionic spider silk with spindle knots is coated with a nano-scale super-hydrophobic layer on the surface of the bionic spider silk. The periodic arrangement of the spindle knots is formed by a group of adjacent two spindle knots to form a recess in the middle, as a drop of water. pool. Specifically include the following steps:

[0032] Step A, pre-treatment of glass fiber: mixing 0.2wt% oil red O dye with photocurable polymer alkali-free glass fiber (EnvisionTEC E-Glass 2.0) under magnetic stirring for 1.5h, the rotating speed of magnetic stirrer is 600r / min. Then conduct an ultrasonic bath for 30 min, with an ultrasonic power of 80 W, to completely dissolve the Oil Red O dye in the glass fiber. Among them, the amount of ...

Embodiment 2

[0037] Step A, pre-treatment of glass fiber: mixing 0.2wt% oil red O dye with photocurable polymer alkali-free glass fiber (EnvisionTEC E-Glass 2.0) under magnetic stirring for 1.5h, the rotating speed of magnetic stirrer is 600r / min. Then conduct an ultrasonic bath for 30 min, with an ultrasonic power of 80 W, to completely dissolve the Oil Red O dye in the glass fiber. Among them, the amount of oil red O dye is 3% of the mass of light-curable alkali-free glass fiber;

[0038]Step B. Preparation of glass fiber / MWCNTs composite material: Mix MWCNTs (MWCNTs length 1-5 μm, outer diameter 5-15 nm) and photocurable alkali-free glass fiber under magnetic stirring conditions for 2.5 hours, and magnetic stirrer The rotating speed is 800r / min, followed by an ultrasonic bath for 30min, and the ultrasonic power is 100W. Among them, the amount of MWCNTs is 3% of the mass of light-curable alkali-free glass fiber;

[0039] Step C, light-curing 3D printing: The 3D printer model is Envisi...

Embodiment 3

[0042] Step A, pre-treatment of glass fiber: mixing 0.2wt% oil red O dye with photocurable polymer alkali-free glass fiber (EnvisionTEC E-Glass 2.0) under magnetic stirring for 1.5h, the rotating speed of magnetic stirrer is 600r / min. Then conduct an ultrasonic bath for 30 min, with an ultrasonic power of 80 W, to completely dissolve the Oil Red O dye in the glass fiber. Among them, the amount of oil red O dye is 5% of the mass of light-curable alkali-free glass fiber;

[0043] Step B. Preparation of glass fiber / MWCNTs composite material: Mix MWCNTs (MWCNTs length 1-5 μm, outer diameter 5-15 nm) and photocurable alkali-free glass fiber under magnetic stirring conditions for 2.5 hours, and magnetic stirrer The rotating speed is 800r / min, followed by an ultrasonic bath for 30min, and the ultrasonic power is 100W. Among them, the amount of MWCNTs is 5% of the mass of light-curable alkali-free glass fiber;

[0044] Step C, light-curing 3D printing: The 3D printer model is Envis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com