A production process of heat-insulating concrete

A production process and concrete technology, which is applied in the production process field of heat-insulating concrete, can solve the problems of no heat insulation effect, and achieve a remarkable effect of heat insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A production process of heat-insulating concrete, the specific steps of which include:

[0054] The parts by weight are: 20 parts by weight of cement, 24 parts by weight of sand, 23 parts by weight of coarse aggregate, 15 parts by weight of fine aggregate, 18 parts by weight of water and 8 parts by weight of glass fiber chopped strands for subsequent use;

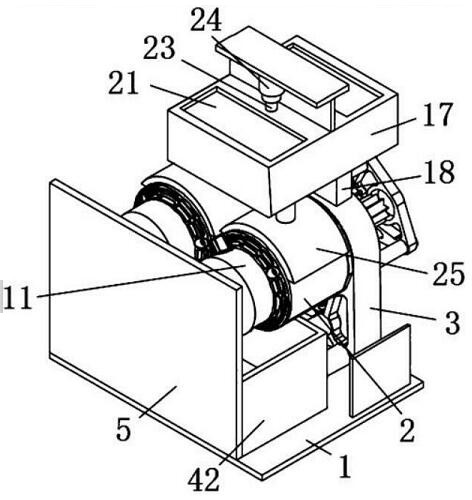

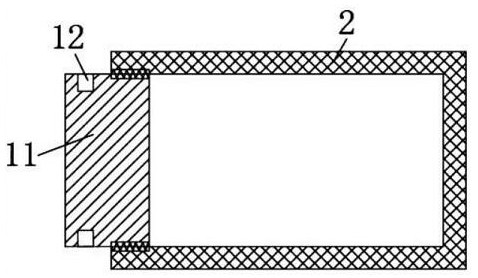

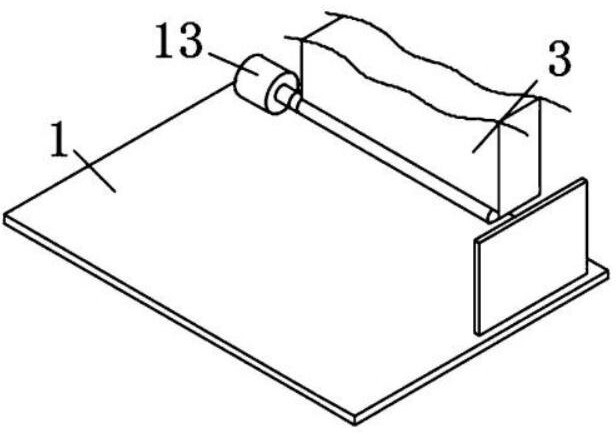

[0055] Place cement, sand, coarse aggregate, fine aggregate, and water in the first storage space 20 of the processing equipment, and place glass fiber chopped strands in the second storage space 20 of the processing equipment;

[0056] The first hydraulic rod 24 located above the first storage space 20 works to drive the movement of the material retaining plate 22 through the fixed rod 23. When the material retaining plate 22 moves upward, the material retaining plate 22 is located in the storage space 20, thereby facilitating the storage space 20. Cement, sand, coarse aggregate, fine aggregate, and water in the con...

Embodiment 2

[0080] In Example 1, "20 parts by weight of cement, 24 parts by weight of sand, 23 parts by weight of coarse aggregate, 15 parts by weight of fine aggregate, 18 parts by weight of water and 8 parts by weight of glass fiber chopped strands" were changed to "10 parts by weight of cement Parts by weight, 8 parts by weight of sand, 12 parts by weight of coarse aggregate, 13 parts by weight of fine aggregate, 13 parts by weight of water and 2 parts by weight of glass fiber chopped strands", and the rest are the same as in Example 1.

Embodiment 3

[0082] In Example 1, "20 parts by weight of cement, 24 parts by weight of sand, 23 parts by weight of coarse aggregate, 15 parts by weight of fine aggregate, 18 parts by weight of water and 8 parts by weight of glass fiber chopped strands" were changed to "15 parts by weight of cement Parts by weight, 20 parts by weight of sand, 18 parts by weight of coarse aggregate, 17 parts by weight of fine aggregate, 16 parts by weight of water and 5 parts by weight of glass fiber chopped strands", and the rest are the same as in Example 1.

[0083] The "fixed connection" described in the present invention means that the two parts connected to each other are fixed together, generally by means of welding, screwing or gluing; "rotational connection" means that the two parts are connected together And can move relatively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com