Preparation method of ethyl methylethyl phosphinate

A technology of ethyl methyl ethyl phosphinate and diethyl methyl phosphinate, which is applied in the field of preparation of ethyl methyl ethyl phosphinate, can solve the problem of slow reaction rate and efficiency and difficulties in scale-up , high safety risks and other issues, to achieve safe operation, facilitate large-scale industrial production, and increase the effect of warming probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] MDEP: Diethyl methyl phosphonite

[0035] Using the one-pot method:

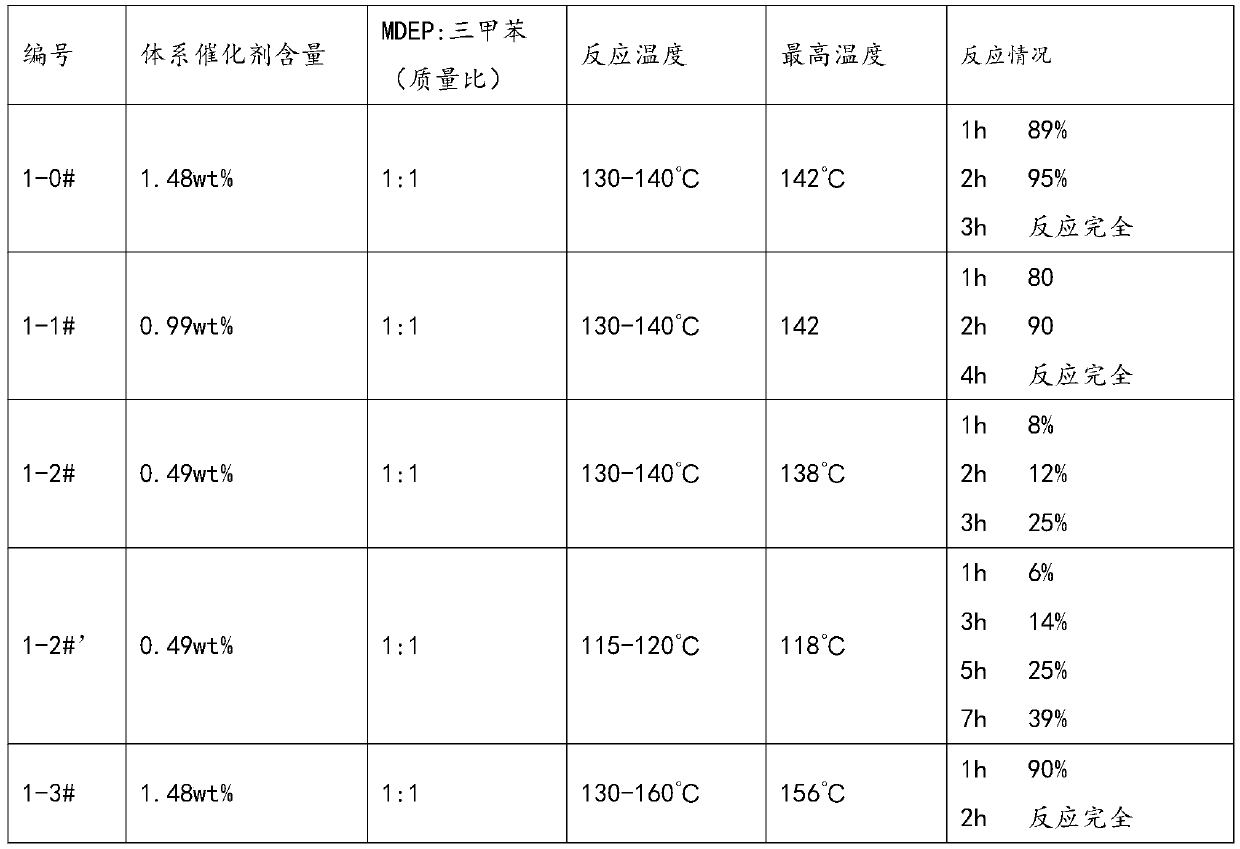

[0036] 1-0#, replace the four-necked flask with nitrogen three times, keep the bottle dry, add 80g of diethyl methylphosphinate and 80g of trimethylbenzene into the four-necked flask, take 2.4g of iodoethane with a syringe, add In the four-necked flask, the catalyst content in the system is 1.48wt%, pay attention to nitrogen protection during the process, set the temperature of the oil bath to 140°C, gradually heat up, and start timing after the temperature of the reaction system in the bottle rises to 130°C, and maintain this state About 3 hours, detected at 1 hour, the target product was 89%; detected at 2 hours, the target product was 95%; detected at 3 hours, the reactants were completely converted, and the target product was 97%. There was no obvious temperature rise during the reaction, the highest The temperature was 142°C.

[0037] For 1-1#, the proportion of catalyst content in the system w...

Embodiment 2

[0044] Add dropwise in batches, there is trimethylbenzene:

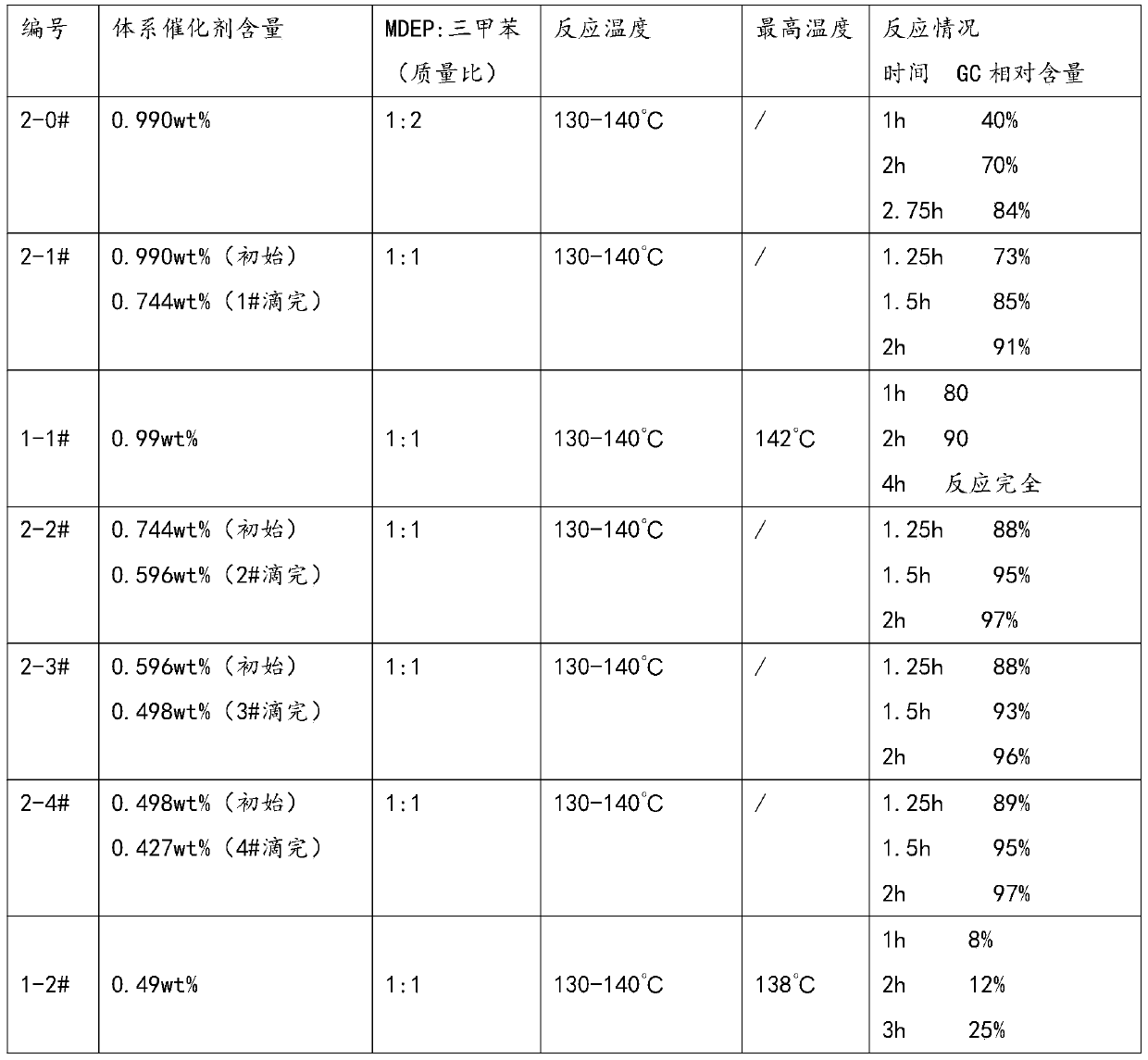

[0045] The four-neck flask was replaced with nitrogen three times to keep the inside of the flask dry. Divide 1100g of diethyl methylphosphonite into 5 parts (0#, 1#, 2#, 3#, 4#), each with an average of 220g. Add diethyl methylphosphonite 0# and 440g trimethylbenzene into the four-necked flask, take 6.6g iodoethane with a syringe, and add it into the four-necked flask, pay attention to nitrogen protection during the process. Set the temperature of the oil bath to 140°C, gradually heat up, and start timing after the temperature of the reaction system in the bottle rises to 130°C, and maintain this state for about 2 hours.

[0046] Subsequently, maintain the internal temperature of the reaction system at 130-140°C, and continuously drop diethyl methylphosphonite 1# to 4# into the reaction system using a syringe pump. Each batch of drops takes 1 hour, and each batch Start timing when dropping, and detect the content ...

Embodiment 3

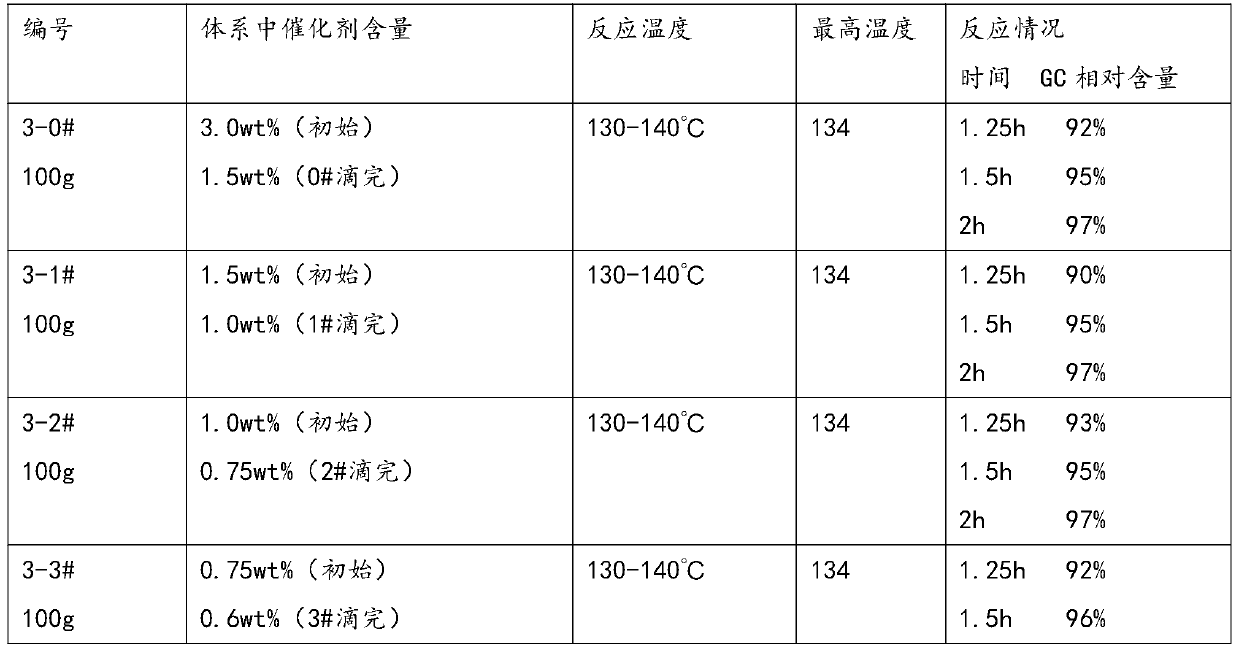

[0051] Add dropwise, without trimethylbenzene, ethyl methyl ethyl phosphinate as substrate:

[0052] The four-neck flask was replaced with nitrogen three times to keep the inside of the flask dry. Divide 700g of diethyl methylphosphonite into 7 parts (0#, 1#, 2#, 3#, 4#, 5#, 8#), with an average of 100g each; in addition, prepare 2 additional parts of methylphosphonite Diethyl phosphonate, respectively 800g diethyl methylphosphonite 6# and 1500g diethyl methylphosphonite 7#. Add 100 g of ethyl methyl ethyl phosphinate into the four-necked flask, take 3 g of ethyl iodide with a syringe, and add it into the four-necked flask, paying attention to nitrogen protection during the process. Set the temperature of the oil bath to 140°C, gradually heat up until the temperature of the reaction system in the bottle rises to 130°C, then start timing, maintain the internal temperature of the reaction system at 130-140°C, and continuously add methylphosphine into the reaction system with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com