Photodegradable PE wrapping film and preparation method thereof

A stretch film and photodegradation technology, applied in the field of packaging materials, can solve the problems of white pollution of PE stretch film, achieve high transparency, improve self-adhesiveness, and improve antistatic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

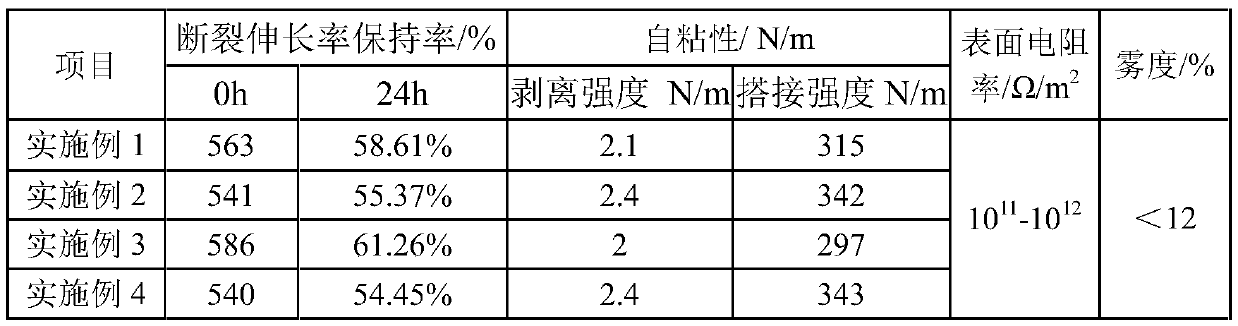

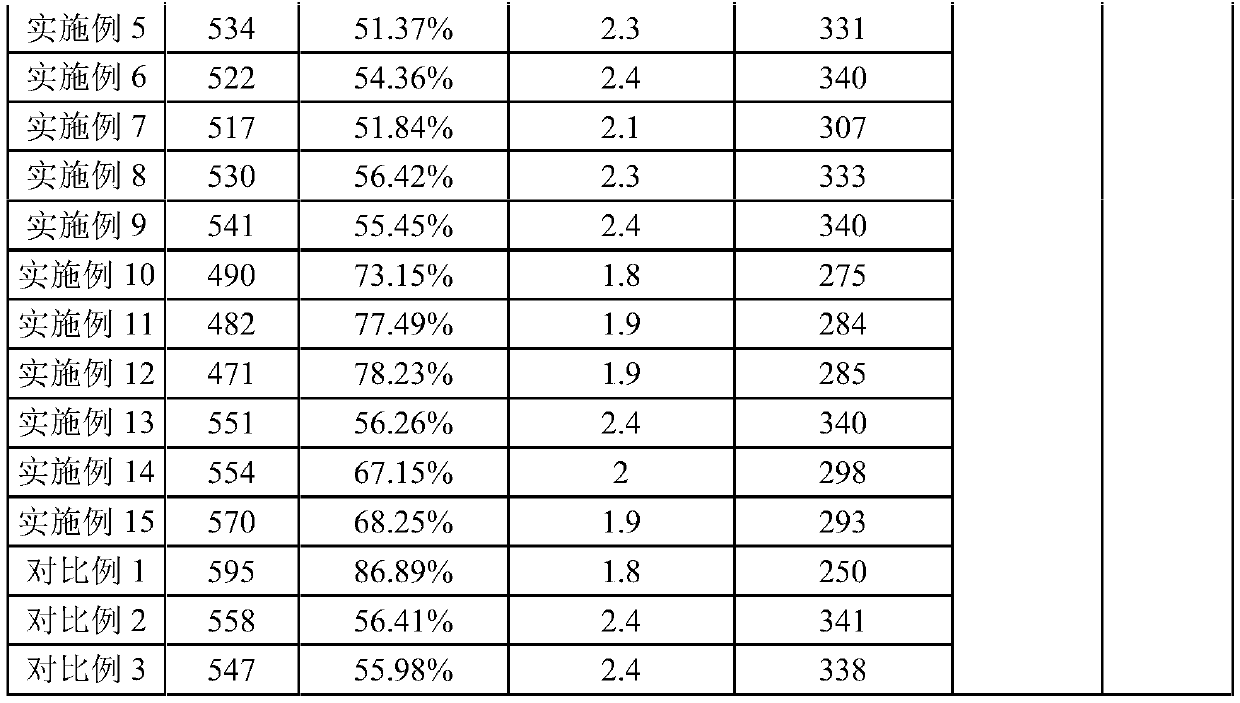

Examples

Embodiment 1

[0038] Preparation of modified LLDPE by slurry method:

[0039] 1) The polymerization reactor is dried, vacuumized, and replaced with nitrogen for 3 times;

[0040] 2) Introduce 1.0bar hydrogen into the polymerization reactor, add 300 parts of isobutane, start stirring at a speed of 300rpm, and add the main catalyst-supported TiCl 4 / MgCl 2 and cocatalyst triethylaluminum, so that the amount concentration of the main catalyst substance (calculated as titanium) is 2×10 -5 -2×10 -4 mol / L, the ratio of the amount of substance of Al / Ti in the promoter and the main catalyst is 60-120 (molar ratio);

[0041] 3) Raise the temperature of the polymerization reactor in the previous step to 80°C, add 10 parts of 1-butene, 15 parts of 1-hexene, 1.67 parts of diacetone acrylamide, and 8.33 parts of methyl vinyl ketone at a constant temperature, and continuously feed ethylene gas, Control the total pressure to 10 bar, and react for 2 hours at a constant temperature to carry out slurry p...

Embodiment 2

[0048] The rest is the same as in Example 1, except that when the modified LLDPE is prepared by the slurry method, the amount of diacetone acrylamide is 3.75 parts, and the amount of methyl vinyl ketone is 6.25 parts.

Embodiment 3

[0050] The rest are the same as in Example 1, except that when the modified LLDPE is prepared by the slurry method, the amount of 1-butene is 2 parts, and the amount of 1-hexene is 5 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com