A kind of preparation method of peek modified ptfe profile continuous extrusion

A profile and continuous technology, which is applied in the field of continuous extrusion of PEEK modified PTFE profiles, can solve the problems of difficult processing of PTFE materials, complicated preparation processes, and inability to continuous production, and achieve good wear resistance, increased dispersibility, high The effect of tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

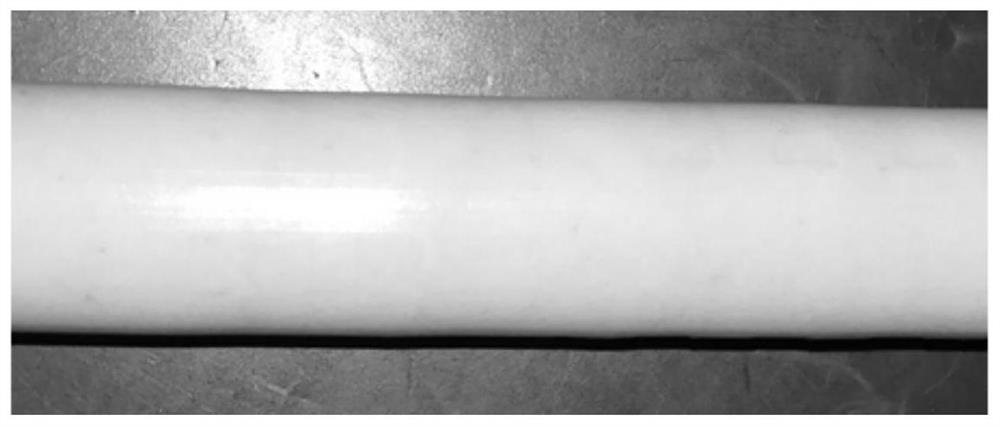

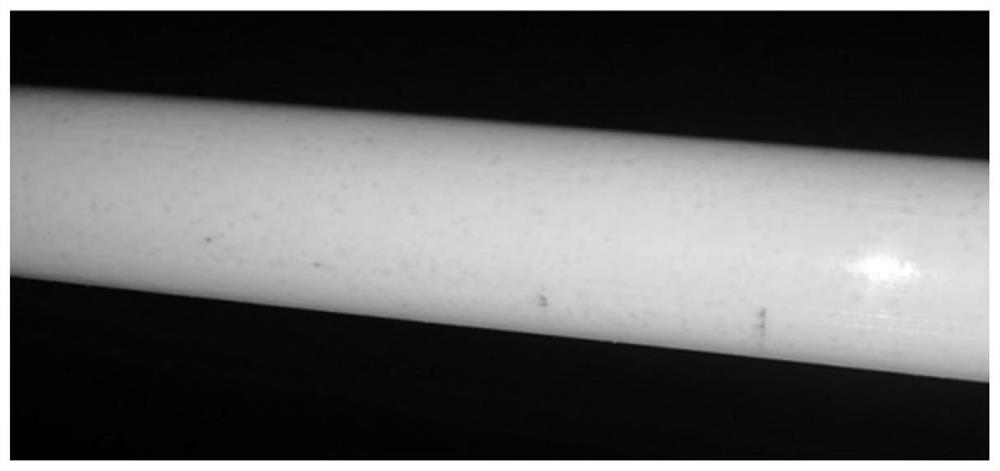

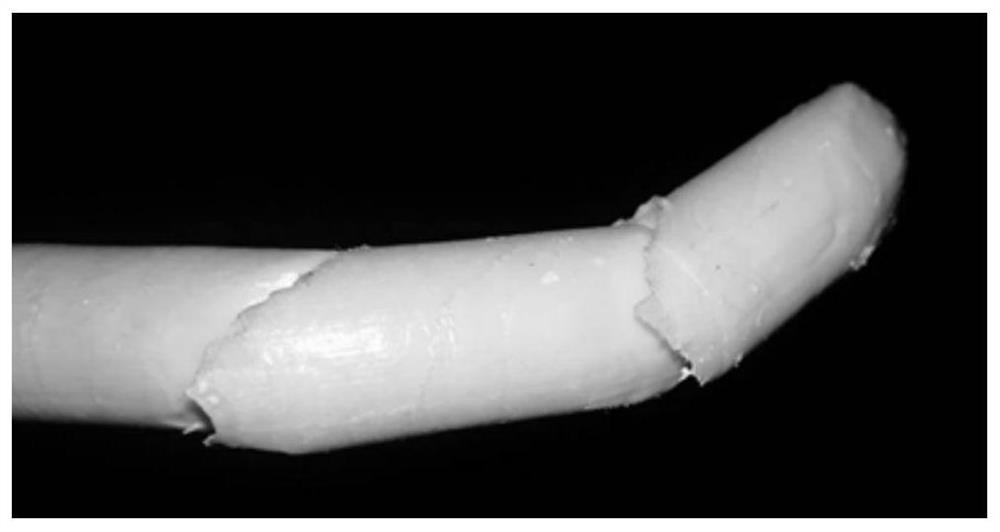

Image

Examples

Embodiment 1

[0029] A preparation method for continuous extrusion of PEEK modified PTFE profiles, comprising the steps of:

[0030] (1) Cool the PTFE material in an ice room with a temperature of less than 0°C for 2 hours to ensure that the PTFE does not agglomerate and agglomerate. After cooling, take it out and pre-mix it with PEEK, dispersant-stearamide and paraffin for multiple times to form a mixture material, the pre-mixing is carried out with a mixer, and the mixer is connected with cooling water to cool down the mixer to ensure that the temperature of the mixture is lower than 40 ° C, mixing 5 times, each time for 3 minutes; wherein the PTFE The mass ratio to PEEK is 9:1; the amount of stearamide and paraffin added accounts for 0.15% of the total mass of PTFE and PEEK, and the mass ratio of stearamide to paraffin is 1:2;

[0031] (2) Add the mixture of step (1) into the plunger extruder for continuous extrusion. The barrel temperature of the plunger extruder is 390° C. The time is...

Embodiment 2

[0034] A preparation method for continuous extrusion of PEEK modified PTFE profiles, comprising the steps of:

[0035] (1) Cool the PTFE material in an ice room with a temperature of less than 0°C for 1 hour to ensure that the PTFE does not agglomerate and agglomerate. After cooling, take it out and pre-mix it with PEEK, dispersant-stearamide several times to form a mixture. The premixing is carried out with a mixer, and the mixer is connected with cooling water to cool down the mixer, ensuring that the temperature of the mixture is lower than 40°C, and mixing 6 times, each time for 1 minute; wherein the PTFE and PEEK The mass ratio is 9:0.5; the amount of stearamide added accounts for 0.1% of the total mass of PTFE and PEEK;

[0036](2) Add the mixture of step (1) into the plunger extruder for continuous extrusion. The barrel temperature of the plunger extruder is 370° C. The time is 80s, the die compression ratio of the plunger extruder is 1.5, and finally a PEEK modified P...

Embodiment 3

[0038] A preparation method for continuous extrusion of PEEK modified PTFE profiles, comprising the steps of:

[0039] (1) The PTFE material is placed in an icehouse with a temperature of less than 0°C for cooling for 3 hours to ensure that the PTFE does not agglomerate and agglomerate, and after cooling, it is taken out and premixed with PEEK, dispersant-paraffin for multiple times to form a mixture. The pre-mixing is carried out with a mixer, and the mixer is connected with cooling water to cool down the mixer, ensuring that the temperature of the mixture is lower than 40°C, and mixing 3 times for 5 minutes each time; the quality of the PTFE and PEEK The ratio is 9:0.8; the amount of paraffin added accounts for 0.4% of the total mass of PTFE and PEEK;

[0040] (2) Add the mixture of step (1) into the plunger extruder for continuous extrusion. The barrel temperature of the plunger extruder is 380° C. The time is 30s, the die compression ratio of the plunger extruder is 1.8, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com