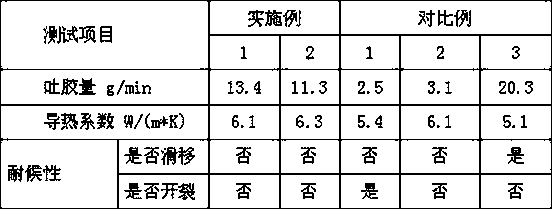

High-thermal-conductivity gel composition with excellent weather resistance

A gel composition and weather resistance technology, which is applied in the field of thermally conductive materials, can solve the problems of being unable to maintain the original position, the temperature rise of the heating device, and the failure of heat transfer function, etc., and achieve excellent weather resistance, promote dispersion, and improve thermal conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

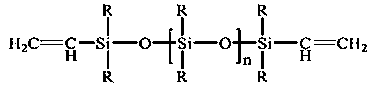

[0026] A high thermal conductivity gel composition with excellent weather resistance, including 100 parts of vinyl silicone oil, 8 parts of crosslinking agent, 5 parts of chain extender, 0.2 part of acetylene cyclohexanol inhibitor, 0.3 part of 8000ppm cast platinum catalyst , 5 parts of γ-glycidyl etheroxypropyl trimethoxysilane KH-560, 2300 parts of thermal conductive powder.

[0027] Vinyl silicone oil has a viscosity of 200mPa*s and a vinyl content of 0.26mmol / g.

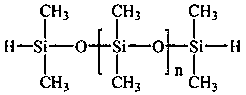

[0028] The viscosity of the hydrogen-containing silicone oil on the side of the crosslinking agent is 120 mPa·s, and the content of hydrogen groups is 1.5 mmol / g.

[0029] The viscosity of the hydrogen-containing silicone oil at the end of the chain extender is 60 mPa·s, and the hydrogen group content is 0.5 mmol / g.

[0030] 2300 parts of thermal conductive powder include 150 parts of nano-zinc oxide, 300 parts of nano-alumina, 150 parts of angular alumina with a diameter of 10um, 600 parts of spherical alumina...

Embodiment 2

[0033] A high thermal conductivity gel composition with excellent weather resistance, including 100 parts of vinyl silicone oil, 15 parts of crosslinking agent, 8 parts of chain extender, 0.2 part of acetylene cyclohexanol inhibitor, 0.3 part of 8000ppm cast platinum catalyst , 5 parts of γ-glycidyl etheroxypropyl trimethoxysilane KH-560, 2300 parts of thermal conductive powder.

[0034] Vinyl silicone oil has a viscosity of 50mPa·s and a vinyl content of 0.63mmol / g.

[0035] The viscosity of the hydrogen-containing silicone oil on the side of the crosslinking agent is 120 mPa·s, and the content of hydrogen groups is 1.5 mmol / g.

[0036] The viscosity of the hydrogen-containing silicone oil at the end of the chain extender is 60mPa·s, and the hydrogen group content is 0.5mmol / g.

[0037] 2300 parts of thermal conductive powder include 150 parts of nano-zinc oxide, 300 parts of nano-alumina, 300 parts of angular alumina with a diameter of 10um, 550 parts of spherical alumina w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com