EVA hot melt adhesive, preparation process and application thereof

A technology of hot-melt adhesives and reactors, applied in adhesives, adhesive types, mineral oil hydrocarbon copolymer adhesives, etc., can solve the problems of easy rebound, short opening time, waste, etc., and achieve strong anti-rebound ability, The effect of high bond strength and long open time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

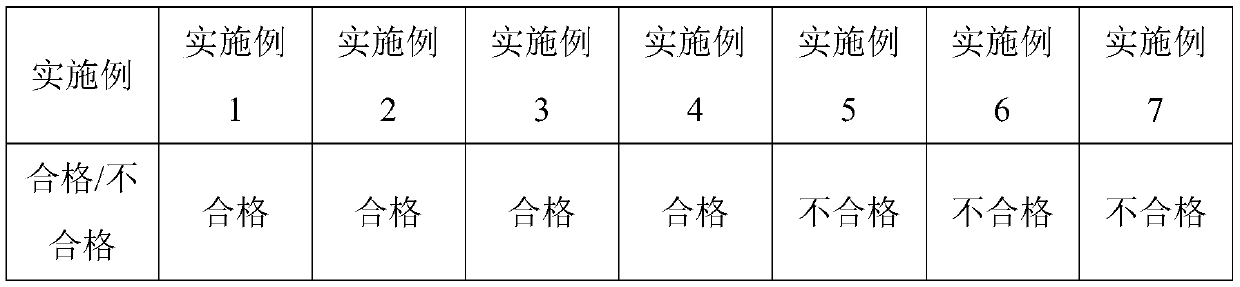

Examples

preparation example Construction

[0075] Second aspect of the present invention provides the preparation method of described EVA hot-melt adhesive, at least comprise the following steps:

[0076] (1) Add vinyl acetate-ethylene copolymer and wax to the reaction kettle, heat to 70-130°C while stirring, and continue stirring until the mixture is uniform;

[0077] (2) Add antioxidant into the reaction kettle, continue heating to 130-170°C, and stir until evenly mixed;

[0078] (3) Add rosin resin and petroleum resin into the reaction kettle, stir for 30-60 minutes, cool down to 120-150°C, and discharge to obtain the product.

[0079] The third aspect of the present invention provides the application of the EVA hot melt adhesive, which is applied to the field of carton sealing and packaging for furniture packaging

[0080] In a more preferred embodiment, the EVA hot melt adhesive is especially suitable for the field of sealing and packaging of large cartons and cartons containing overweight items.

Embodiment 1

[0085] Embodiment 1 provides an EVA hot-melt adhesive, which comprises the following components by weight percentage: 45% of vinyl acetate-ethylene copolymer, 39% of tackifying resin, 15% of wax, and 1% of auxiliary agent.

[0086] The vinyl acetate-ethylene copolymer is selected from American DuPont, model 210W; the tackifying resin is a combination of petroleum resin and rosin resin, and the weight ratio is 1:8; 120S; the rosin resin is selected from Guangzhou Kemao Chemical, model 146; the wax is polyethylene wax, selected from Honeywell, model Ac6A; the auxiliary agent is an antioxidant, selected from Foshan Yuansheng Chemical Industry Co., Ltd., the model is Yuansheng-1010.

[0087] The preparation method of described EVA hot-melt adhesive, comprises the following steps:

[0088] (1) Add vinyl acetate-ethylene copolymer and wax to the reaction kettle, heat to 110°C while stirring, and continue stirring until the mixture is uniform;

[0089] (2) Add antioxidant into the ...

Embodiment 2

[0092] Embodiment 2 provides an EVA hot-melt adhesive, which comprises the following components by weight percentage: 50% of vinyl acetate-ethylene copolymer, 30% of tackifying resin, 19.9% of wax, and 0.1% of auxiliary agent.

[0093]The vinyl acetate-ethylene copolymer is selected from American DuPont, model 210W; the tackifying resin is a combination of petroleum resin and rosin resin, and the weight ratio is 1:5; 120S; the rosin resin is selected from Guangzhou Kemao Chemical, model 146; the wax is polyethylene wax, selected from Honeywell, model Ac6A; the auxiliary agent is an antioxidant, selected from Foshan Yuansheng Chemical Industry Co., Ltd., the model is Yuansheng-1010.

[0094] The preparation method of described EVA hot-melt adhesive, comprises the following steps:

[0095] (1) Add vinyl acetate-ethylene copolymer and wax to the reaction kettle, heat to 110°C while stirring, and continue stirring until the mixture is uniform;

[0096] (2) Add antioxidant into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com