Engine oil dilution calculation method

A calculation method and technology of engine oil, applied in the direction of engine lubrication, mechanical equipment, engine components, etc., can solve the problems affecting the performance of diesel engines, shortening the service life of diesel engines, increasing the cost of use, etc., to reduce the dilution rate of engine oil, improve the use effect, The effect of saving user cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

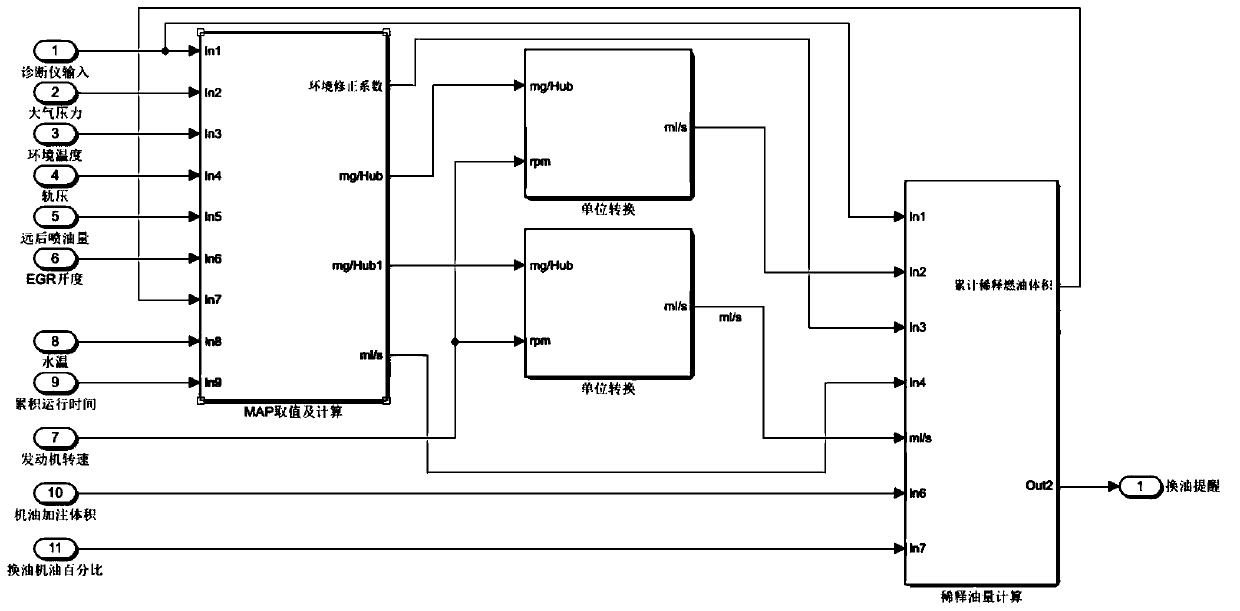

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0024] A calculation method for engine oil dilution, comprising the following steps:

[0025] (1) Calculate the fuel volume V0 (ml) in the oil when the oil needs to be replaced according to the oil replacement index given by the lubricating oil company and the total amount of oil filled;

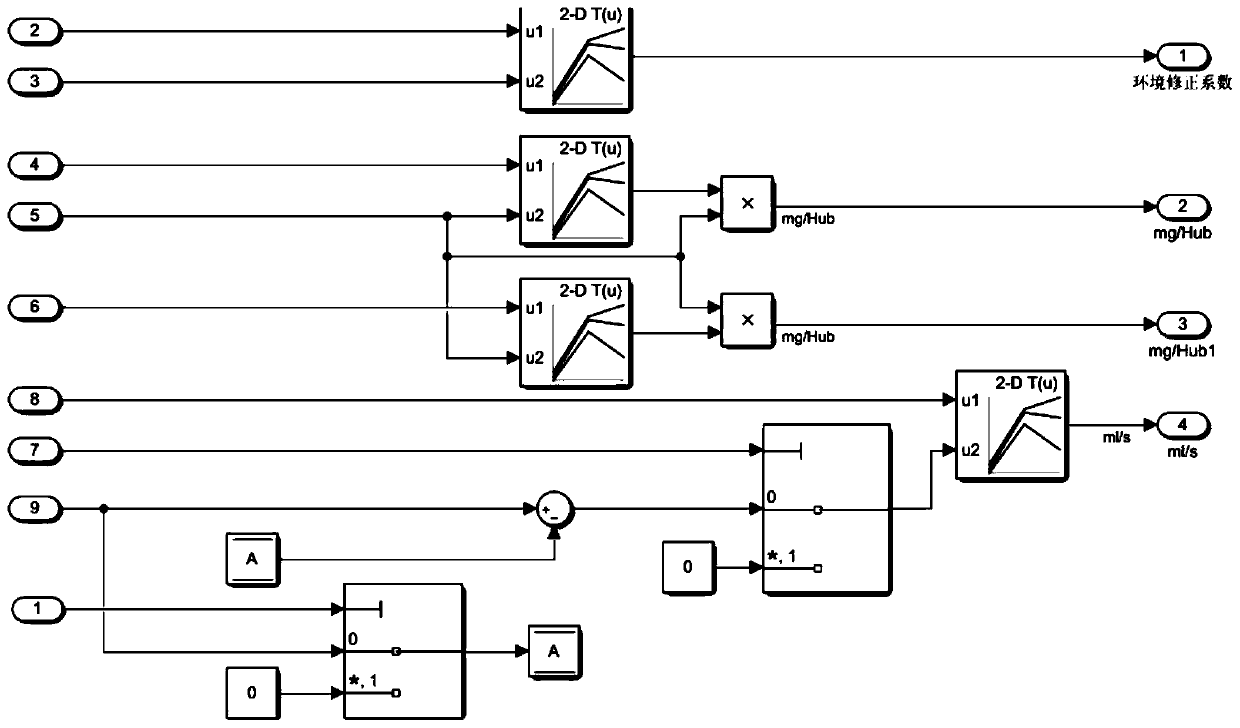

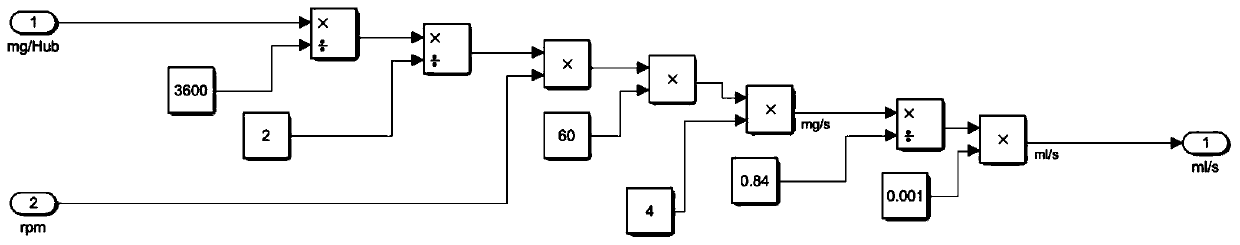

[0026] (2) According to the rail pressure and the MAP output oil dilution coefficient of the far rear fuel injection quantity q, multiply the far rear fuel injection quantity q to obtain the base fuel quantity in the engine oil, and obtain the fuel growth rate in the engine oil per unit time after unit conversion q1(mg / s);

[0027] (3) Carry out environmental factor correction, the fuel growth rate q1 is multiplied by the coefficient a obtained from the revised MAP of the ambient pressure and the ambient temperature, and the fuel growth rate a*q1 (ml / s) in the engine oil a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com