Method and device for evaluating burning loss performance of tungsten electrode

An evaluation method and technology for tungsten electrodes, which can be applied in measuring devices, material analysis by electromagnetic means, material weighing, etc., and can solve problems such as abnormal changes in quality and evaluation deviation of tungsten electrode welding burnout performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] This embodiment provides a method for evaluating the burning performance of tungsten electrodes. Samples 1 to 6 in Table 1 are tested according to the following method:

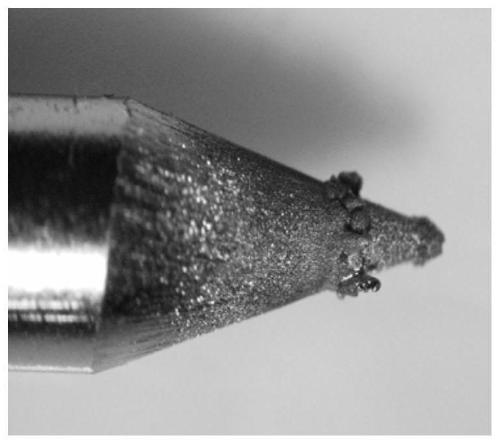

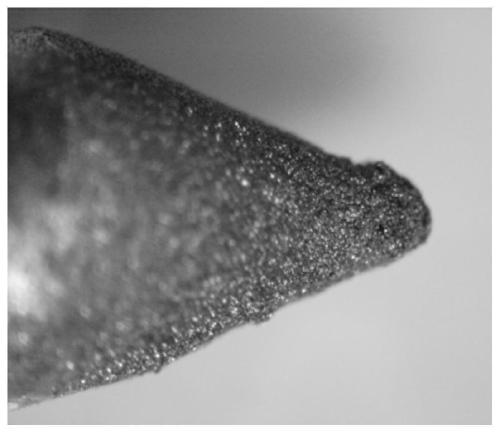

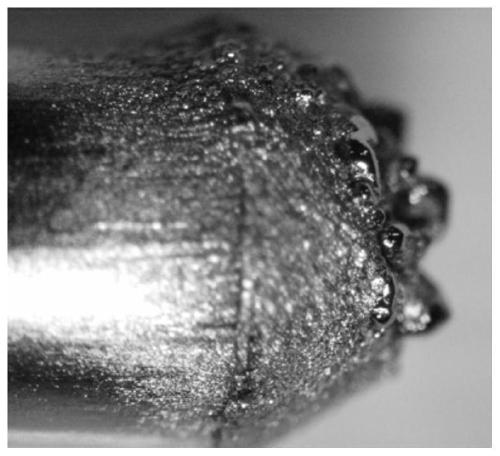

[0069](1) Grind the tip of the tungsten electrode to be evaluated into a 45° cone angle, put it into the welding torch, and fix it in the electrode holding device of the welding torch. The extension length of the tungsten electrode is 3mm, and connect it to the DC power supply as the cathode , and connected together with the water-cooled copper anode into a welding path. Among them, the copper block of the water-cooled copper anode has a smooth surface with a surface roughness of Ra=0.8 μm, and the distance between the discharge end of the tungsten electrode to be evaluated and the water-cooled copper anode is 3 mm.

[0070] (2) Turn on the welding power supply and weld under an argon atmosphere. The purity of argon is 99.999%, and the flow rate of argon is 7L / min; cooling water is used in the welding ...

Embodiment 2

[0076] This example provides an evaluation method for the burning performance of tungsten electrodes. Samples 1 to 6 in Table 1 are tested using a method similar to that of Example 1. The difference is that in this example, the arc voltage to be up to 1.05 times U 1 , cut off the test current and stop arcing.

[0077] The test results of this example are similar to those of Example 1, and the judging results are the same as those of Example 1, which shows that the evaluation method of Example 2 can achieve accurate measurement of the burning loss performance.

Embodiment 3

[0079] This example provides an evaluation method for the burning performance of tungsten electrodes. Samples 1 to 6 in Table 1 are tested using a method similar to that of Example 1. The difference is that in this example, the arc voltage to be up to 1.15 times U 1 , cut off the test current and stop arcing.

[0080] The test results of this example are similar to those of Example 1, and the judgment results are the same as those of Example 1, which shows that the evaluation method of Example 3 can achieve accurate measurement of the burning loss performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com