Power battery tab heat dissipation system based on coupling of phase change material and U-shaped flat heat pipe

A flat heat pipe and phase change material technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of low thermal conductivity of diaphragm materials, poor heat transfer effect, poor thermal conductivity, etc., to improve safety and reliability, reduce Risk of external short-circuit accident, effect of reducing functional breakdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

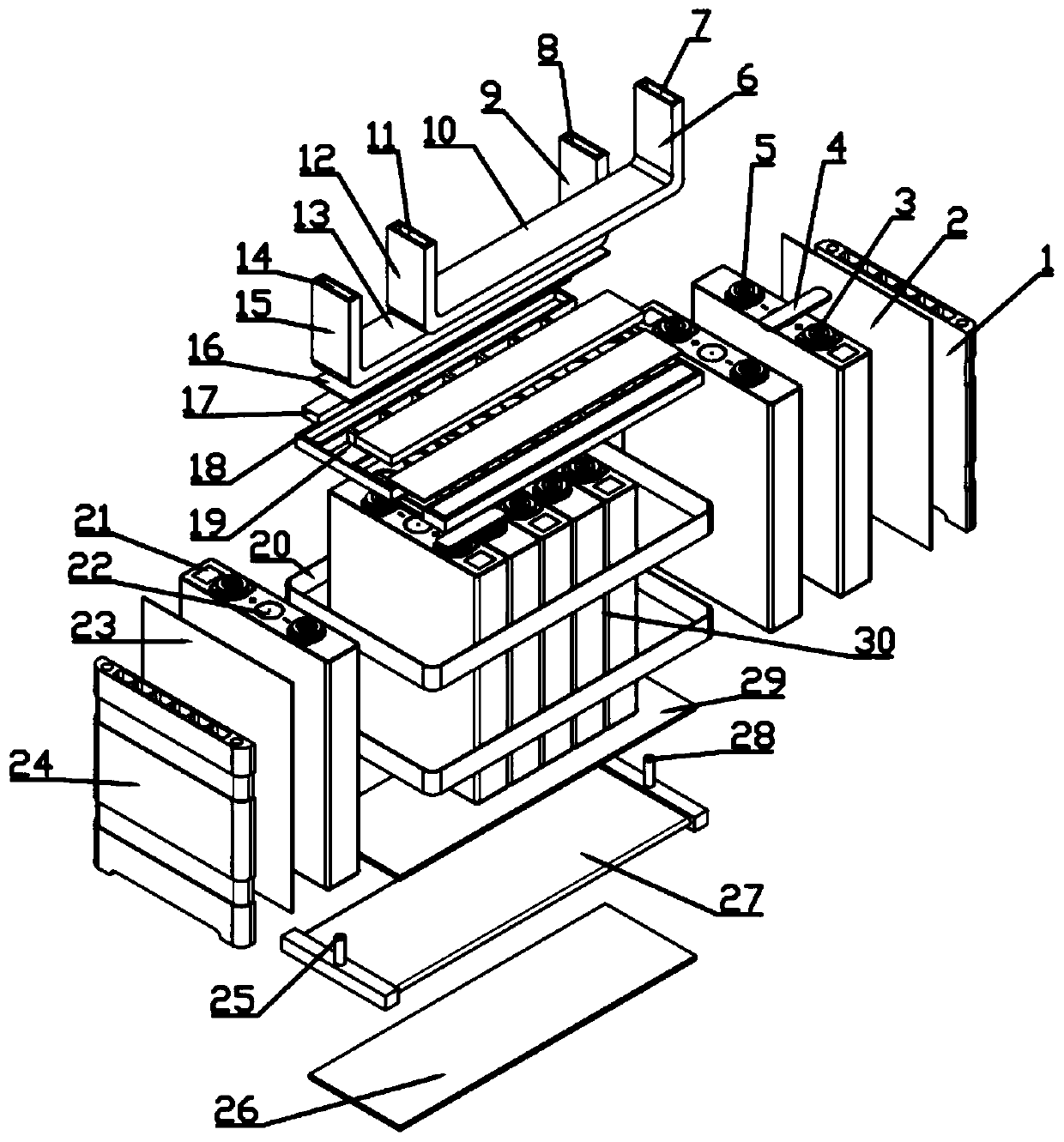

[0017] The present invention is described in more detail below in conjunction with accompanying drawing example:

[0018] combine figure 1 , the present invention provides a power battery tab heat dissipation system based on the coupling of phase change materials and U-shaped flat heat pipes, through the combined heat dissipation of the battery tabs and the bottom, and coupling phase change materials, heat pipes and three different heat management methods of liquid cooling technology , to realize the complementary advantages of each; the U-shaped flat heat pipe can efficiently dissipate heat from the battery module, dissipate heat to the phase change material module in a timely and rapid manner, and further improve the temperature uniformity of the system. The specific embodiments of the present invention are as follows.

[0019] Such as figure 1 As shown, the present invention is a power battery tab cooling system based on the coupling of phase change materials and U-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com