Power battery thermal management system based on tab and module bottom combined liquid cooling heat dissipation

A heat management system, liquid cooling and heat dissipation technology, applied in the direction of secondary batteries, circuits, electrical components, etc., can solve the problems of low thermal conductivity, poor heat transfer effect, and poor thermal conductivity of diaphragm materials, so as to achieve good heat dissipation effect and prevent The effect of external short circuit phenomenon and high temperature uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

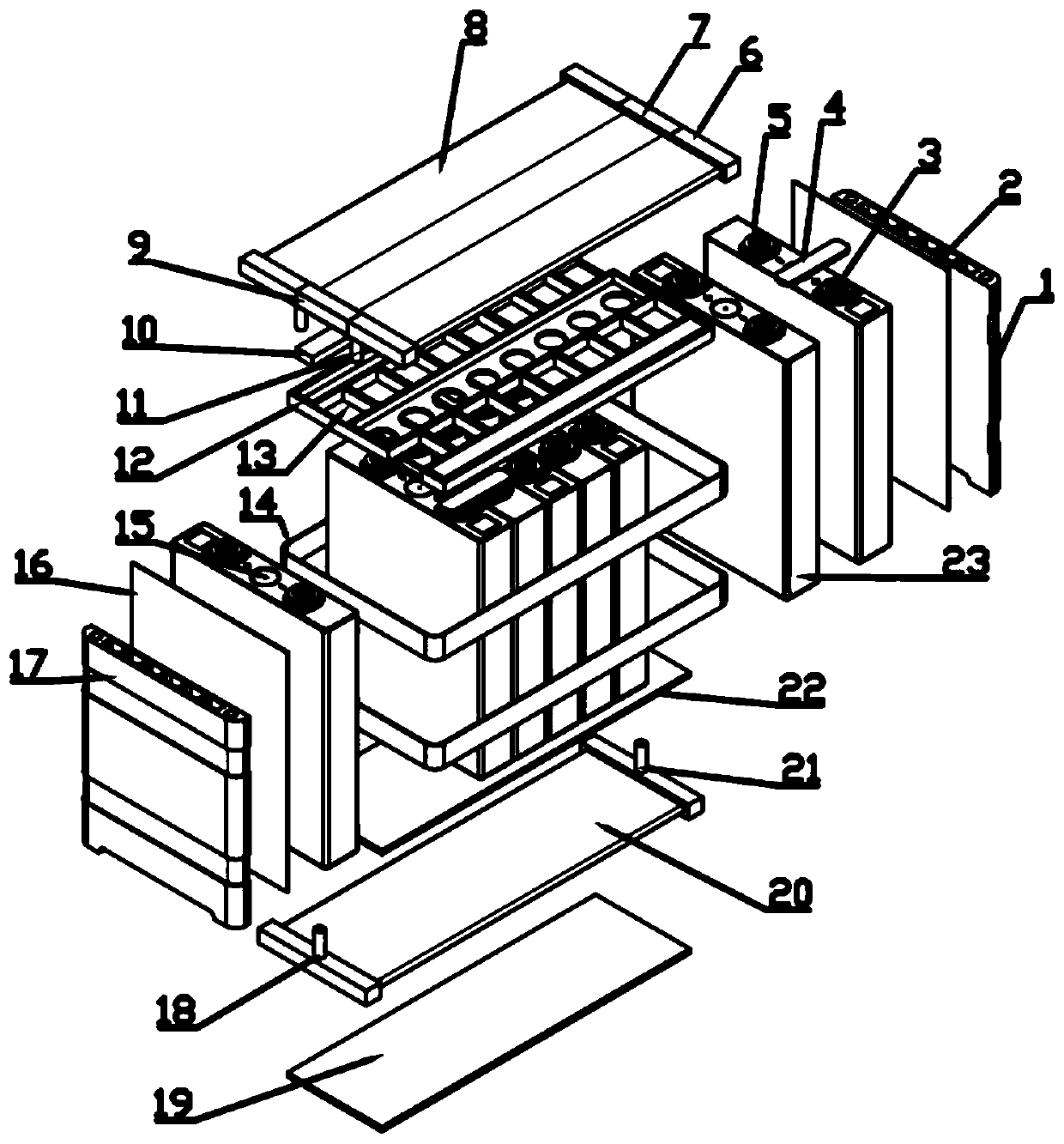

[0016] The present invention is described in more detail below in conjunction with accompanying drawing example:

[0017] combine figure 1 , the present invention provides a power battery thermal management system based on the joint liquid cooling and heat dissipation of the tabs and the bottom of the battery cell. The battery pack is clamped by the liquid cooling plate on the top and bottom of the system, and the combination of multiple spatial dimensions is used for efficient liquid cooling and heat dissipation; isolation The thermally conductive filling glue provided in the frame increases the heat exchange contact area between the tab and the top liquid cooling plate. The present invention couples the heat management method of tab heat dissipation, which can greatly reduce the heat transfer resistance of the system, efficiently dissipate heat from the battery module, ensure that the power battery is in a suitable temperature range, and further improve the temperature unifo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com