Conservation tillage method for total returning of maize straws in rows

A corn stalk and protective technology is applied in the field of protective farming where the corn stalk is returned to the field in full, which can solve the problems of underutilized agricultural crop resources, many corn planting and production links, difficulty in ensuring the quality of sowing, and the like, so as to increase production. Significant income increase, beneficial to soil fertility, and significant social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

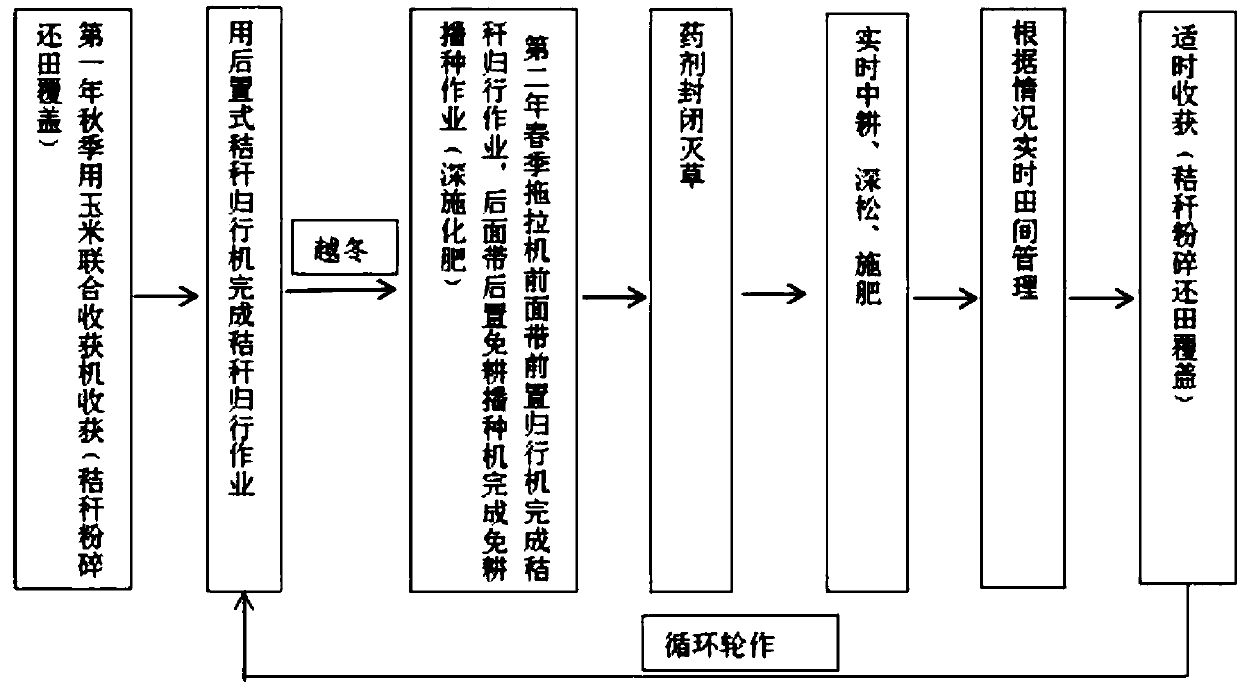

[0022] Maize is planted in a wide and narrow row rotation pattern of conservation tillage, such as figure 1 As shown, in the autumn of the first year, the corn combine harvester is used for harvesting, the straw crushing device is turned on, and the straw is crushed and sprayed evenly on the field at the same time as harvesting. The stalks are collected to the planting row (with stubble) of the first year, and the fallow row of the first year is left for planting corn in the second year and overwintering. In the spring of the second year, after a winter of wind blowing and livestock trampling, some of the stalks returned in the fall of the first year were scattered on the sowing belt of the second year. Therefore, in the spring of the second year, the tractors carried forward The built-in straw return machine can thoroughly clean up a small amount of straw on the sowing belt, so that it will not have any impact on the sowing, and the no-tillage seeder will go into the field at...

Embodiment 2

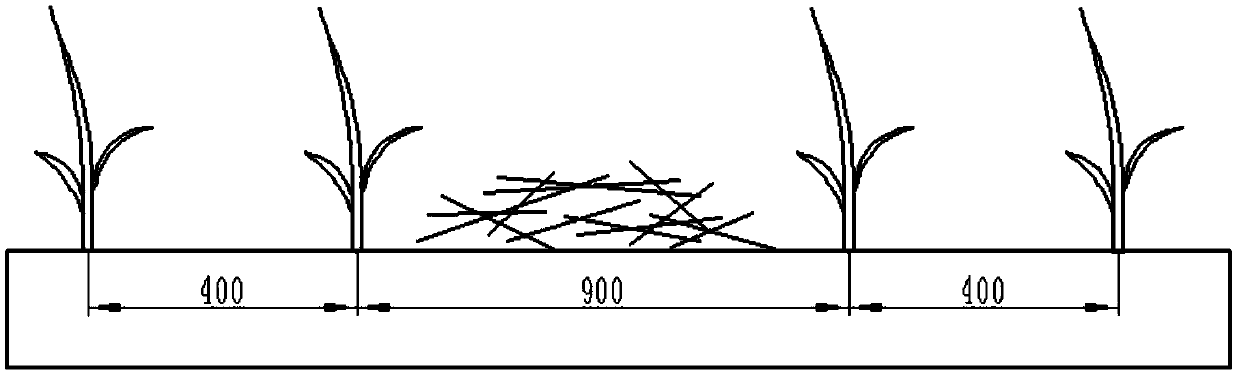

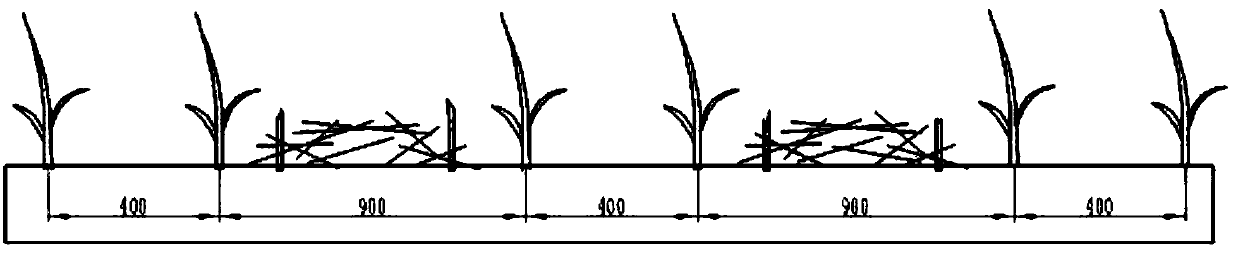

[0024] Such as figure 2 As shown, the corn is planted in the rotation pattern of wide and narrow rows (wide row 900mm, narrow row 400mm) of conservation tillage, and the crushed straw in the autumn harvest of the first year is collected to the planting row of the first year (400mm wide) by the straw returning machine. ), clear the sowing belt and reserve it for no-till sowing corn in the second year. Such as image 3 As shown, in the second year, the leisure row (900mm) of the first year is cleaned out and becomes the sowing belt (400mm wide) of the second year, and the straw is gathered on the sowing belt of the first year (with a width of 400mm) by the straw returning machine. There are root stubbles, 400mm wide), the sowing belt in the first year becomes the leisure row in the second year, the straw is placed alternately, and the sowing belt is alternately rotated. Through the action of wind, sun, rain and soil microorganisms, the straw is gradually reduced and returned ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com