High-yield and high-quality cultivating method for brassica oleracea var.acephala in plant factory condition

A cultivation method and kale technology are applied in the field of high-yield and high-quality cultivation of kale under plant factory conditions, which can solve problems such as premature senescence, accumulation of nitrates, imbalanced proportions, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0060] The plant factory laboratory is equipped with three independent plant factories that can be tested at the same time. Each plant factory is equipped with 6 sets of aluminum profile prefabricated cultivation racks, three-layer structure, layer spacing 50cm, size length 1200mm * width 660mm * height 2350mm. Each group of cultivation racks has an independent circulation system, and the liquid supply of each layer is centralized and returned.

[0061] Smart plant factory IoT mobile APP control interface, which can realize remote detection and control of environmental data, light intensity, temperature, humidity, CO 2 Concentration, nutrient solution EC, pH value, etc.

[0062] The day and night (light 12h, dark 12h) temperature in the plant factory is 25±1°C / 22±1°C, the humidity is 65%, and the CO 2 The concentration is the outside atmospheric CO 2 concentration, the intensity of the light is 200 μmol m -2 ·s -1 .

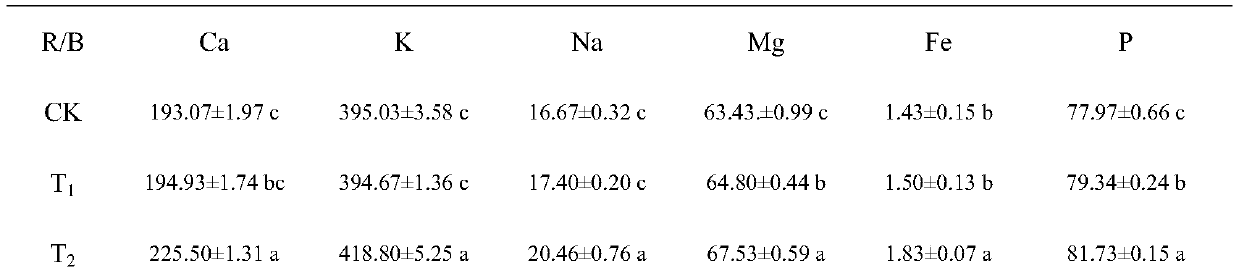

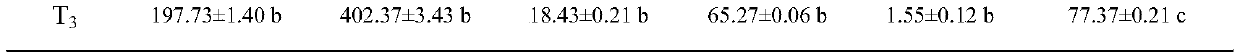

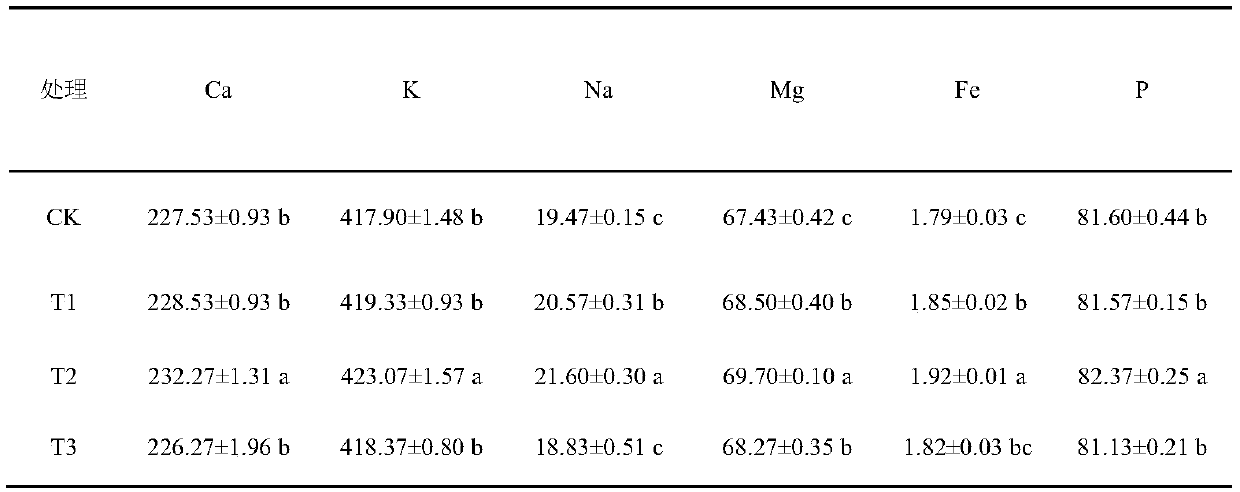

[0063] The tested kale (Brassica oleracea var.acephala...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com