Quantitative packaging equipment for tallow oil protection scraping pad for powdery degreasant production

A quantitative packaging and degreasing agent technology, applied in packaging, packaging protection, transportation and packaging, etc., can solve the problems of product quality including oil film, powder adhesion, powder structure deformation consumption, etc. Reagent particle phenomenon, effect to ensure balance and sufficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

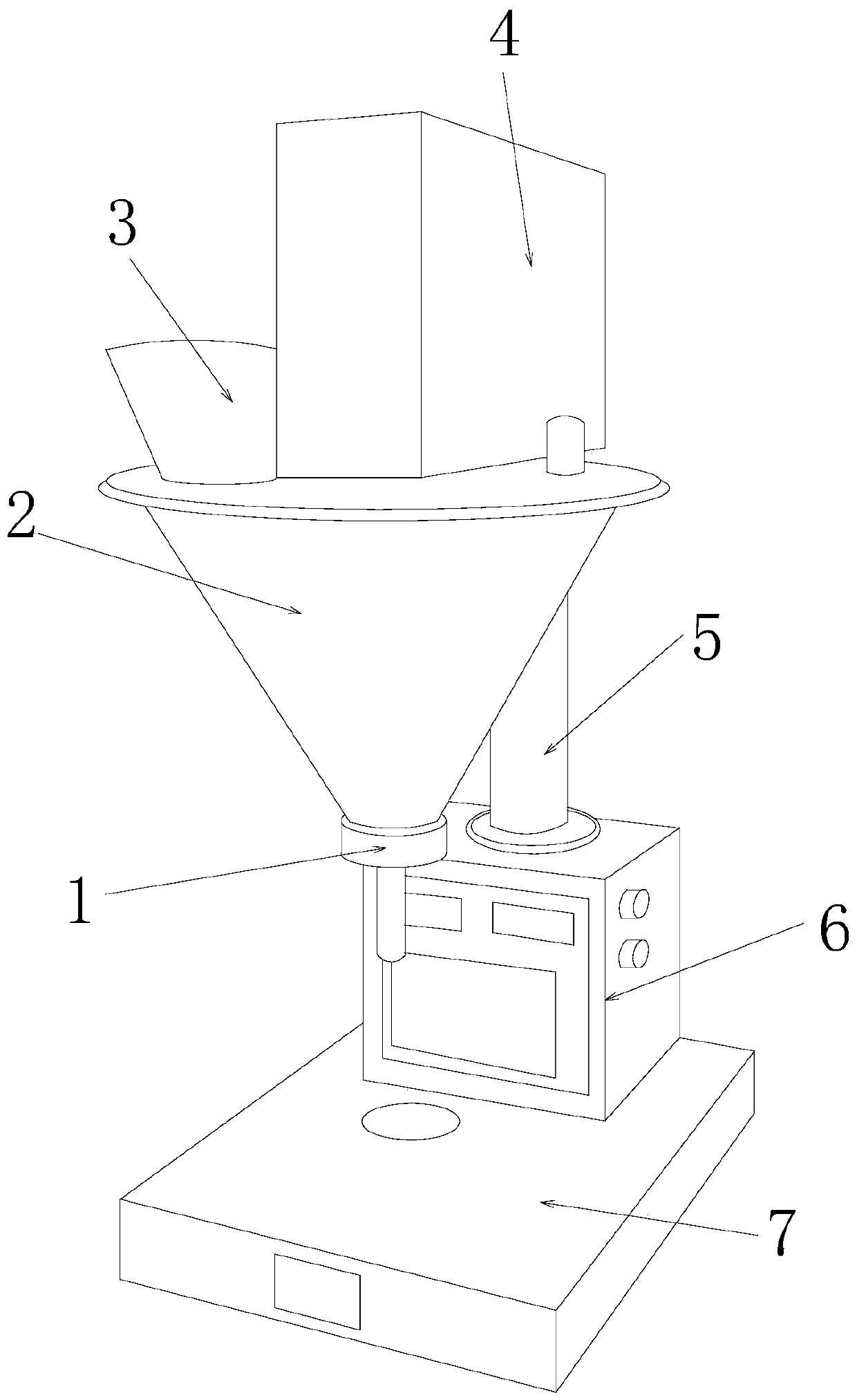

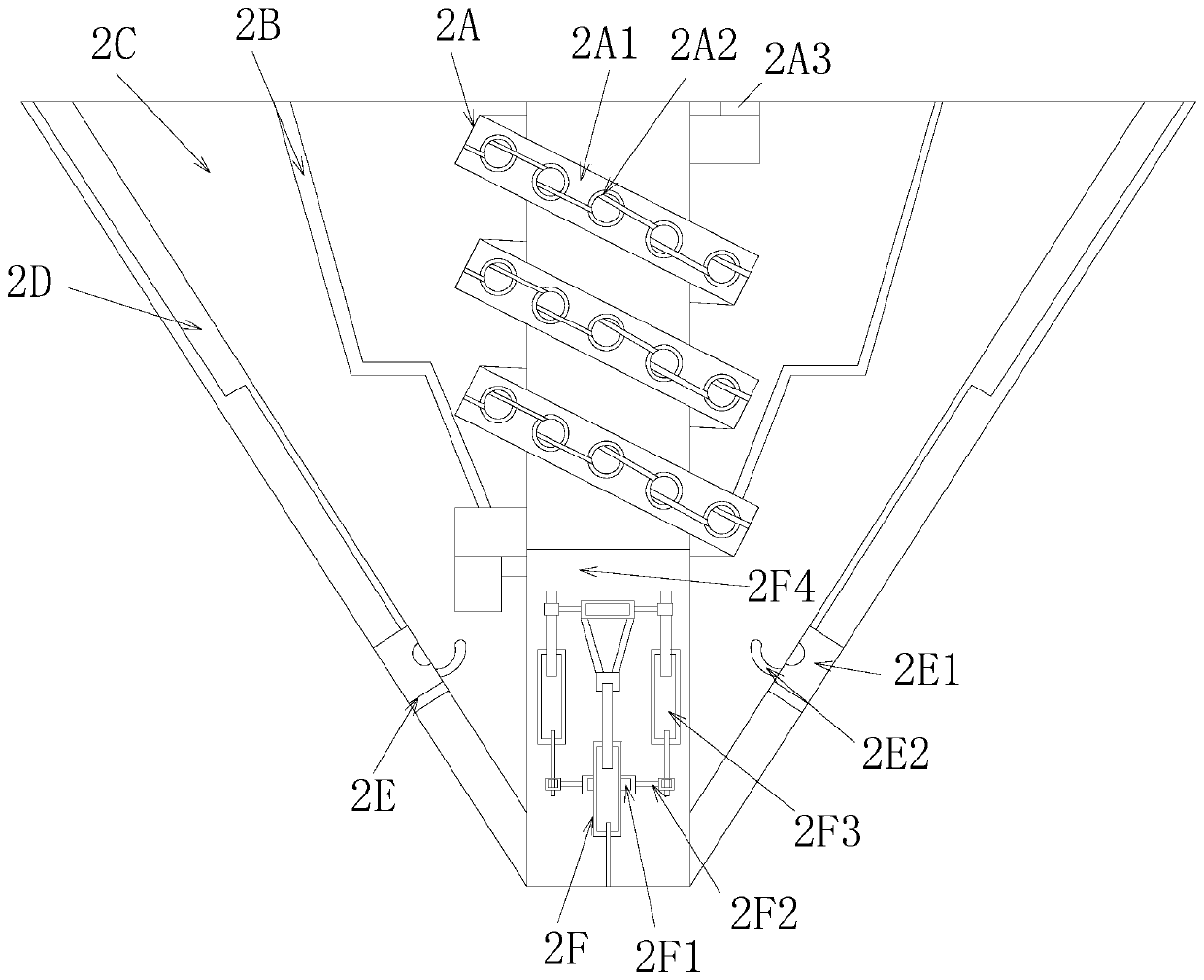

[0032] see Figure 1-Figure 6, the present invention provides a quantitative packaging equipment for grease protection scraper pads used in the production of powdery degreasing agents. Axis column holding arm lever 5, power distribution base 6, bottom backing plate 7, the feeding detection tank 2 is nested on the top of the fixed syringe 1 and the axes are collinear, and the side material guide plate 3 is inserted Embedded in the upper left corner of the feeding detection tank 2, the shaft motor box 4 is installed directly above the feeding detection tank 2, and the shaft motor box 4 is nested on the top of the shaft holding arm 5 And on the same vertical plane, the power distribution base 6 is close to the top surface of the base plate 7 and is on the same horizontal plane, and the power distribution base 6 is electrically connected to the shaft column arm lever 5 through a wire And perpendicular to each other, the feeding detection tank 2 is provided with a centrifugal spri...

Embodiment 2

[0039] see Figure 1-Figure 6 , the present invention provides a kind of quantitative packing equipment of the grease protection scraping pad that powdery degreasing agent is used for production, and other respects are identical with embodiment 1, and difference is:

[0040] see figure 2 , the sorting swivel frame tube 2F is composed of a wheel ring horizontal buckle block 2F1, a short frame rod 2F2, a lifting slide cylinder 2F3, and a swivel frame tube block 2F4. Together and perpendicular to each other, the short frame rod 2F2 and the lifting slide cylinder 2F3 are installed inside the swivel frame block 2F4, and the lifting slide cylinder 2F3 is formed by crossing the upper and lower settling materials through the lock of the wheel ring horizontal buckle block 2F1. As a result, the plugging phenomenon of the quantitative guarantee can be dredged by pushing the cylinder pressure.

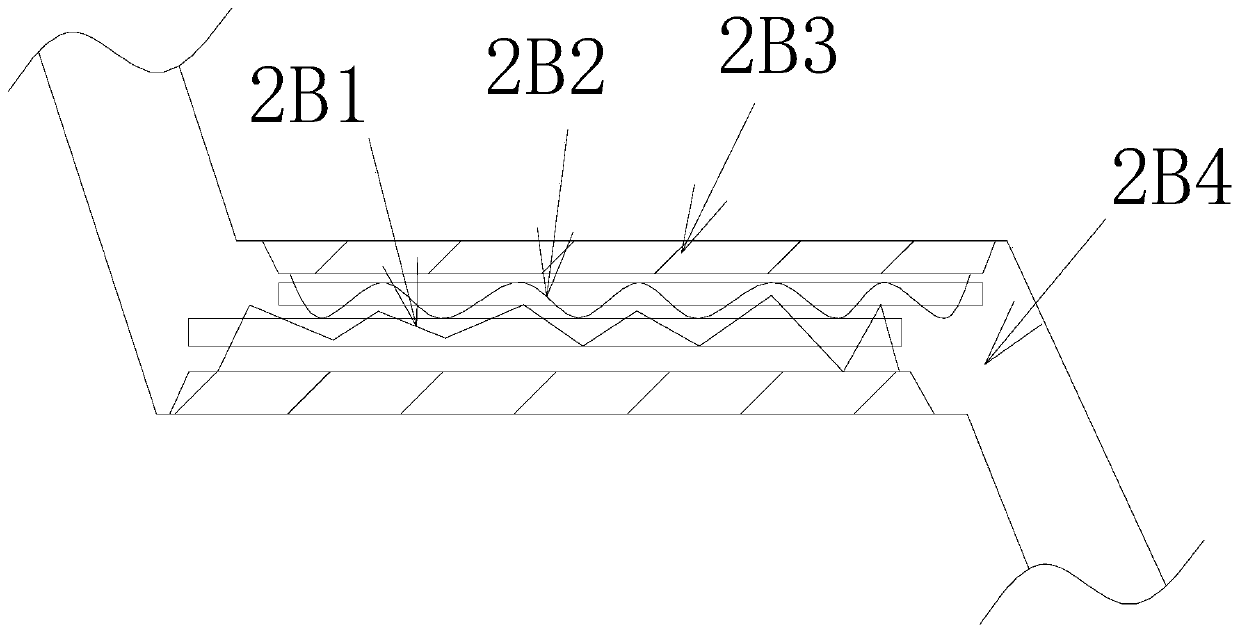

[0041] see Image 6 The horizontal buckle block 2F1 of the wheel ring is composed of an ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com