Wave-absorbing shielding adhesive film and preparation method thereof

A technology of adhesive film and adhesive film layer, applied in the direction of magnetic field/electric field shielding, adhesive, film/sheet adhesive, etc., can solve the problem of demanding product thickness, unsatisfactory thickness and absorption frequency, complex interference of electromagnetic waves and Serious problems, to achieve the effect of suppressing electronic noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

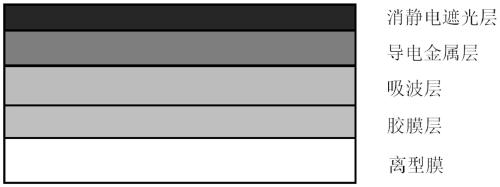

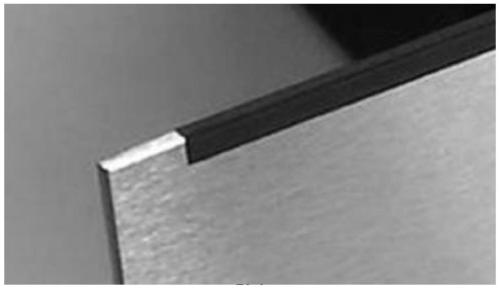

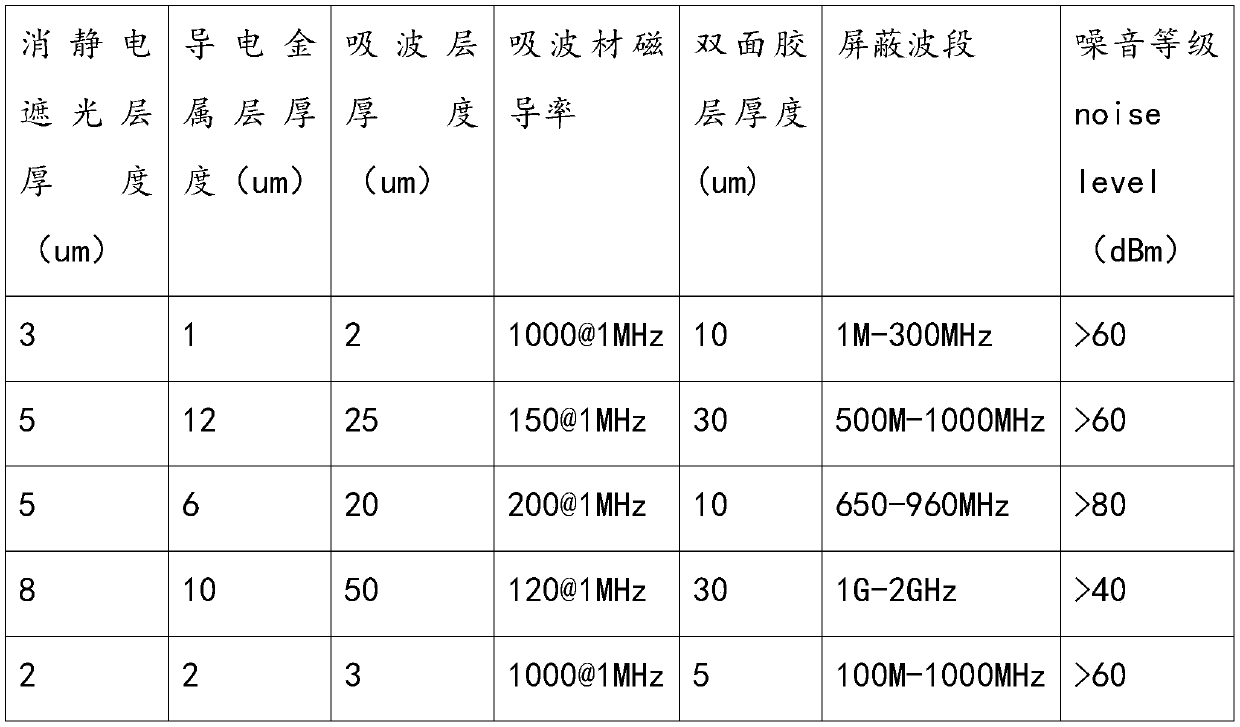

[0024] refer to Figure 1-Figure 2 As shown, the present invention discloses a wave-absorbing shielding adhesive film, which includes an adhesive film layer, a wave-absorbing layer, a conductive metal layer, and a static-dissipating light-shielding layer arranged in sequence. The wave-absorbing layer is made of a soft magnetic alloy material, and the static-dissipating light-shielding layer is Conductive ink or polyimide.

[0025] The conductive metal layer can be copper foil, which has better shielding performance and better thermal conductivity than metal foils such as aluminum foil. The thickness of the conductive metal layer can be 1-50um.

[0026] The adhesive film can be a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com