Al and Ti microalloyed high-strength, high-toughness and medium-entropy alloy and preparation method thereof

A technology of micro-alloying and entropy alloying, which is applied in the field of material processing, can solve the problems of less influence of plastic deformation on the structure and properties of medium-entropy alloys, poor mechanical properties of the workpiece, and high hardness, so as to improve the structure and performance, and improve the strength and toughness , the effect of excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method comprises the following steps:

[0029] 1) Put Co, Ni, Fe, Al and Ti pellets / blocks in a proportioned proportion and place them in a vacuum electric arc furnace, and evacuate to 1×10 -2 ~1×10 -3 Pa, the protective gas is argon, and the pressure in the furnace is 0.05-0.06MPa. During the smelting process, the ingot is continuously turned over at least 5 times to be smelted into an ingot, and the as-cast alloy ingot is homogenized and annealed.

[0030] 2) Forging the cast alloy ingot after homogenizing annealing, and performing homogenizing annealing on the forged alloy block.

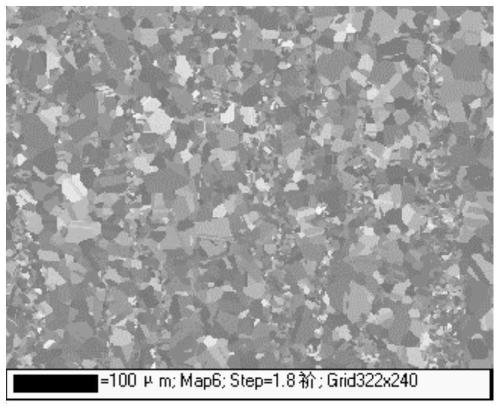

[0031] 3) Heating the forged alloy block to 800-1000° C. for rolling, and performing annealing heat treatment on the rolled alloy block.

[0032] The purity of the Co, Ni, Fe, Al and Ti particles / blocks described in step 1) is all 99.97wt.%.

[0033] The smelting described in step 1) is vacuum arc smelting, and the range of smelting current is 100-300A.

[0034] The ho...

Embodiment 1

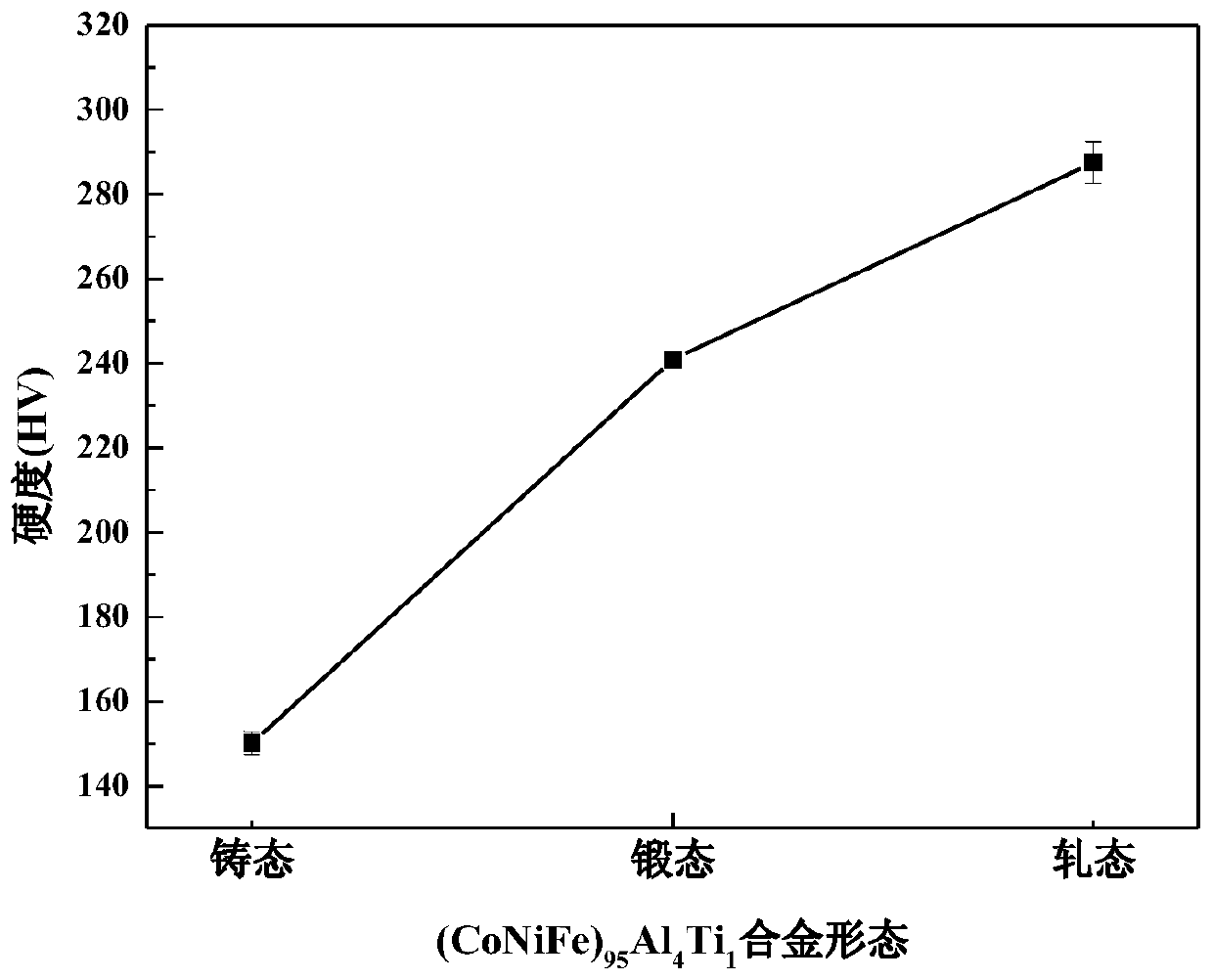

[0040] The composition of the Al and Ti microalloyed high strength and toughness medium entropy alloy of the present invention is (CoNiFe) 95 Al 4 Ti 1 .

[0041] The steps of the preparation method of the above-mentioned Al and Ti microalloyed high-strength and toughness medium-entropy alloy are as follows:

[0042] 1) Put 16.52g of Co ingot, 16.45g of Ni ingot, 15.65g of Fe ingot, 0.96g of Al ingot and 0.42g of Ti ingot into the vacuum arc melting furnace, and evacuate to 1×10 -3 Pa, the protective gas is argon, the pressure in the furnace is 0.05MPa, and the ingot is smelted by repeated turning and melting 5 times. The as-cast alloy ingot was homogenized annealed at 1000°C, kept for 12 hours, and air-cooled.

[0043]2) Forging the alloy ingot after homogenization annealing, and performing homogenization annealing on the forged alloy block.

[0044] First, place the forged alloy ingot in a muffle furnace and heat it to 900°C, then place the cast alloy ingot on the platf...

Embodiment 2

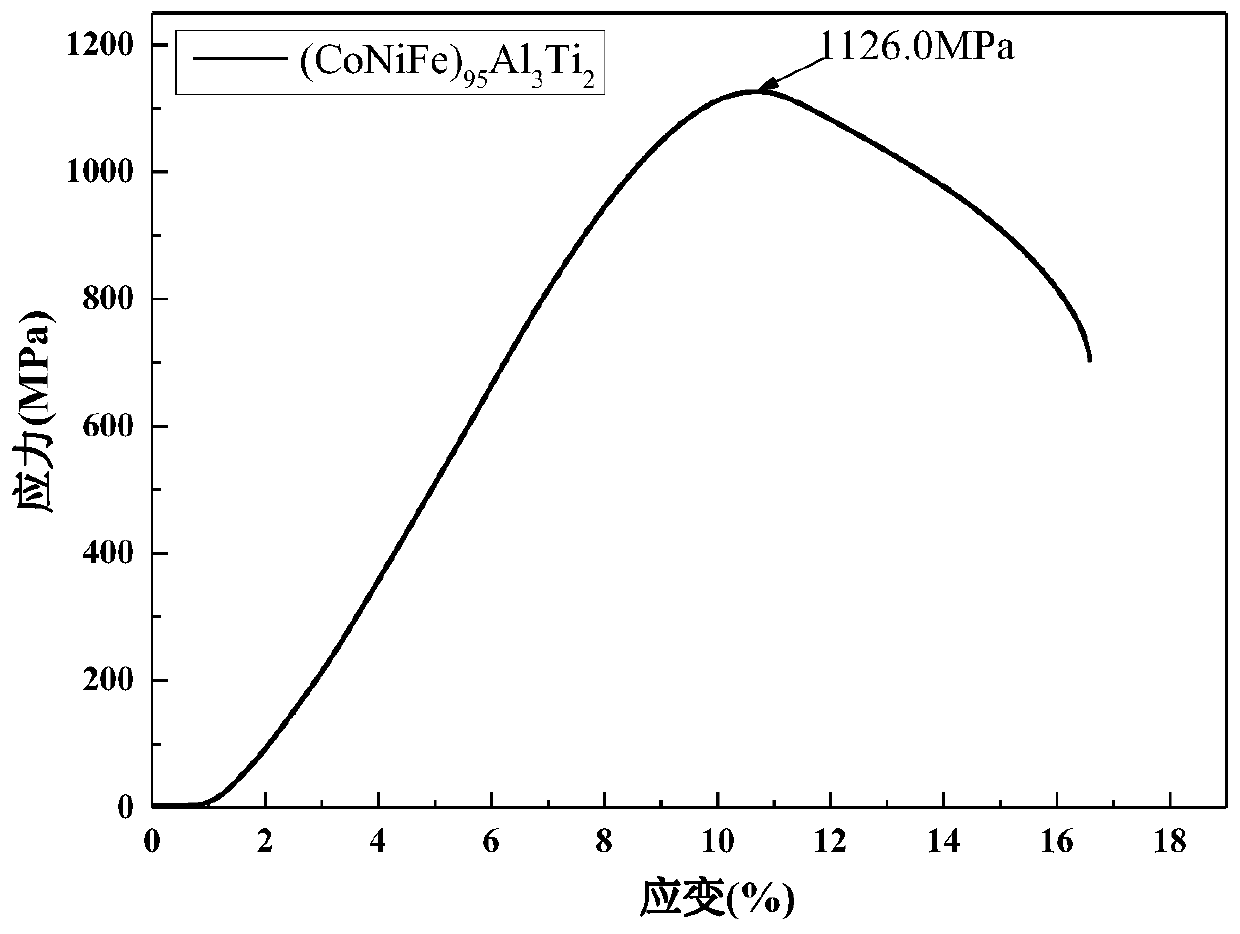

[0048] A kind of Al and Ti microalloying high strength and toughness medium entropy alloy composition of the present invention is (CoNiFe) 95 Al 3 Ti 2 .

[0049] The steps of the preparation method of the above-mentioned Al and Ti microalloyed high-strength and toughness medium-entropy alloy are as follows:

[0050] 1) Put 16.46g of Co ingot, 16.39g of Ni ingot, 15.60g of Fe ingot, 0.71g of Al ingot and 0.84g of Ti ingot into the vacuum arc melting furnace, and evacuate to 1×10 -3 Pa, the protective gas is argon, the pressure in the furnace is 0.05MPa, and the ingot is smelted by repeated turning and melting 5 times. The as-cast alloy ingot was homogenized annealed at 1000°C, kept for 12 hours, and air-cooled.

[0051] 2) Forging the alloy ingot after homogenization annealing, and performing homogenization annealing on the forged alloy block.

[0052] First, place the forged alloy ingot in a muffle furnace and heat it to 900°C, then place the cast alloy ingot on the plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com