P91 material welding and heat treatment method

A heat treatment method, P91 technology, applied in steel material welding and heat treatment, P91 material welding and heat treatment field, can solve the problem of high residual stress in welded joints, improve structure and performance, improve oxidation resistance and high temperature steam corrosion resistance, Effect of Reducing Residual Stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the technical solutions of the present invention clearer and clearer to those skilled in the art, the present invention will be further described in detail below in conjunction with the examples and accompanying drawings, but the embodiments of the present invention are not limited thereto.

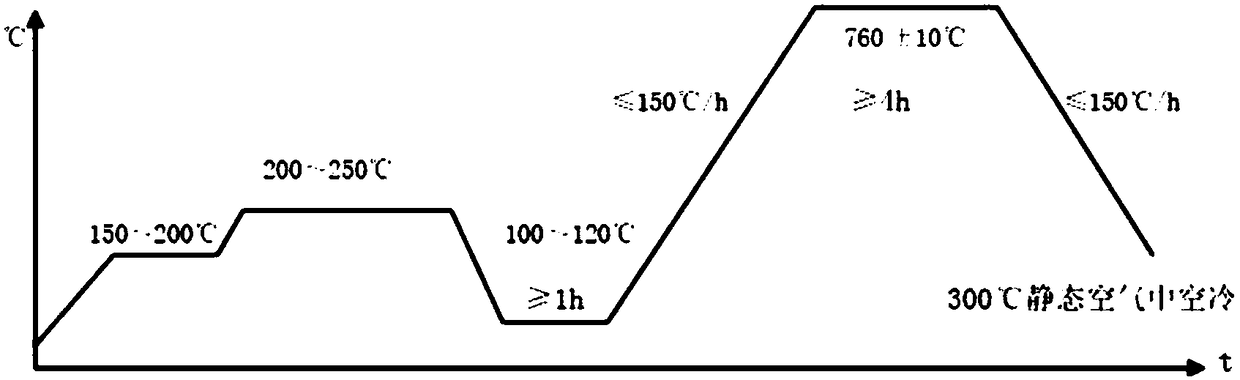

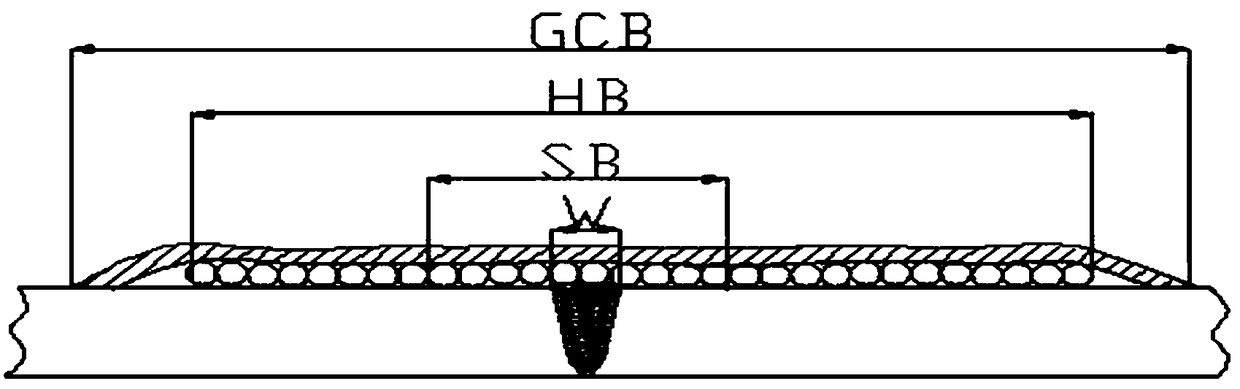

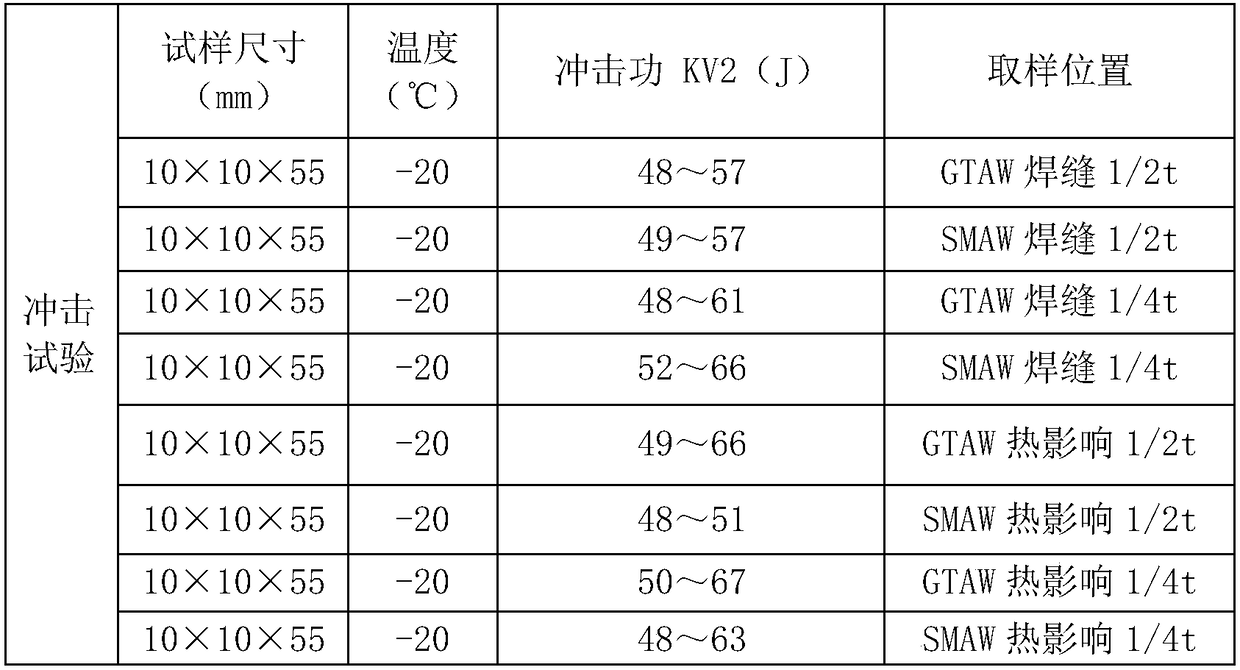

[0035] Such as figure 1 and figure 2 As shown, a kind of P91 material welding and heat treatment method provided in this embodiment includes the following steps:

[0036] Step 1: Preheat

[0037] Set the preheating temperature to 150-200°C and keep it warm for 0.5h;

[0038] Step 2: Soldering

[0039] Use GTAW welding, set the welding current to 130-180A, set the welding voltage to 10-14V, and protect the back of the weld with argon gas with a purity of 99.99%;

[0040] Or use SMAW welding, set the welding current to 160-180A, set the welding voltage to 21-24V, and control the interlayer temperature at 200-250°C;

[0041] Step 3: Keep warm and cool slowly

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com