Environment-friendly dredging vessel for hydraulic engineering

A water conservancy engineering and environmental protection technology, which is applied in the direction of earth movers/shovels, mechanically driven excavators/dredgers, construction, etc. Small and other problems, to achieve the effect of convenient linear motion, small footprint, and increased placement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

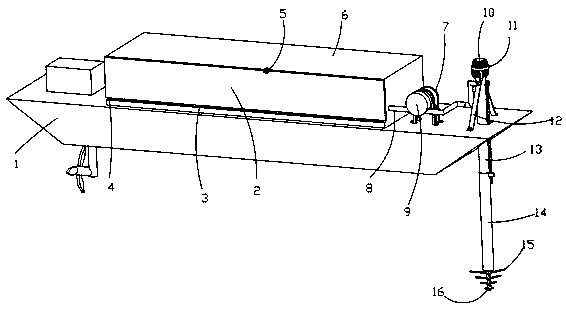

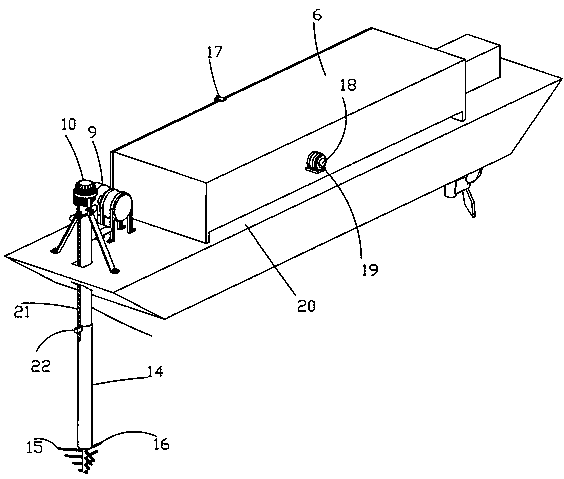

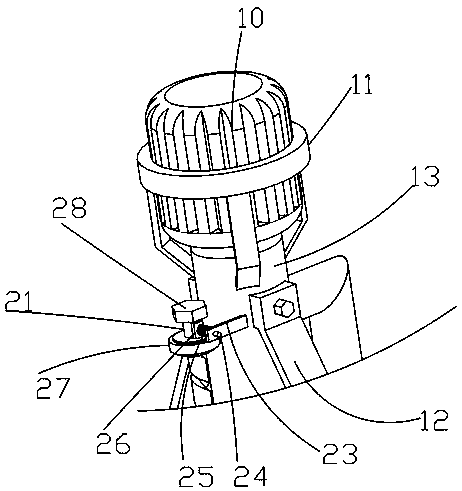

[0031] like Figure 1-7 The shown a kind of environment-friendly dredging ship for water conservancy projects includes a hull 1, and the hull 1 is fixedly connected with a sludge filter box 6, a first mounting frame 7 and a third mounting frame 12, the first mounting frame 7 and the third mounting frame The mounting frame 12 is fixedly connected with the hull 1 by fixing bolts, and the front and rear side walls of the sludge filter box 6 are respectively provided with a horizontal hole 4 and a sewage discharge hole 20, and the bottom of the horizontal hole 4 is flush with the top of the sewage discharge hole 20, and the horizontal hole 4 The top is evenly and fixedly connected with a hinge 3, the hinge 3 is fixedly connected with a door panel 2, the top of the door panel 2 is provided with a movable connection structure, the sludge filter box 6 is provided with a sludge extrusion structure, and the sludge extrusion structure includes a fourth mounting frame 19, an extrusion Pi...

Embodiment 2

[0033] Embodiment 2 is a further improvement to Embodiment 1.

[0034] An environment-friendly dredging ship for water conservancy projects, comprising a hull 1, a sludge filter box 6, a first installation frame 7 and a third installation frame 12 are fixedly connected to the hull 1, and the front and rear side walls of the sludge filter box 6 are respectively provided with The horizontal hole 4 and the sewage discharge hole 20, and the bottom of the horizontal hole 4 is flush with the top of the sewage discharge hole 20, the top of the horizontal hole 4 is evenly and fixedly connected with the hinge 3, the hinge 3 is fixedly connected with the door panel 2, and the top of the door panel 2 is provided with a movable The connection structure, the movable connection structure includes a bump 5 and a latch 17, the sludge treatment box 6 and the door panel 2 are fixedly connected with a bump 5, and the bump 5 is inserted with a latch 17 through a straight hole provided; the sludge fi...

Embodiment 3

[0036] Embodiment 3 is a further improvement to Embodiment 1.

[0037] An environment-friendly dredging ship for water conservancy projects, comprising a hull 1, a sludge filter box 6, a first installation frame 7 and a third installation frame 12 are fixedly connected to the hull 1, and the front and rear side walls of the sludge filter box 6 are respectively provided with The horizontal hole 4 and the sewage discharge hole 20, and the bottom of the horizontal hole 4 is flush with the top of the sewage discharge hole 20, the top of the horizontal hole 4 is evenly and fixedly connected with the hinge 3, the hinge 3 is fixedly connected with the door panel 2, and the top of the door panel 2 is provided with a movable connection structure, the sludge filter box 6 is provided with a sludge extruding structure, the first installation frame 7 is fixedly connected with a sludge pump 9, and both ends of the sludge pump 9 are fixedly connected with a sludge delivery pipe 8, and the slu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com